Winding machine control system

A control system and winding machine technology, applied in the electrical field, can solve the problems of difficult automatic control and low control precision, and achieve the effects of stable and reliable work, good control effect, and good dynamic and static characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

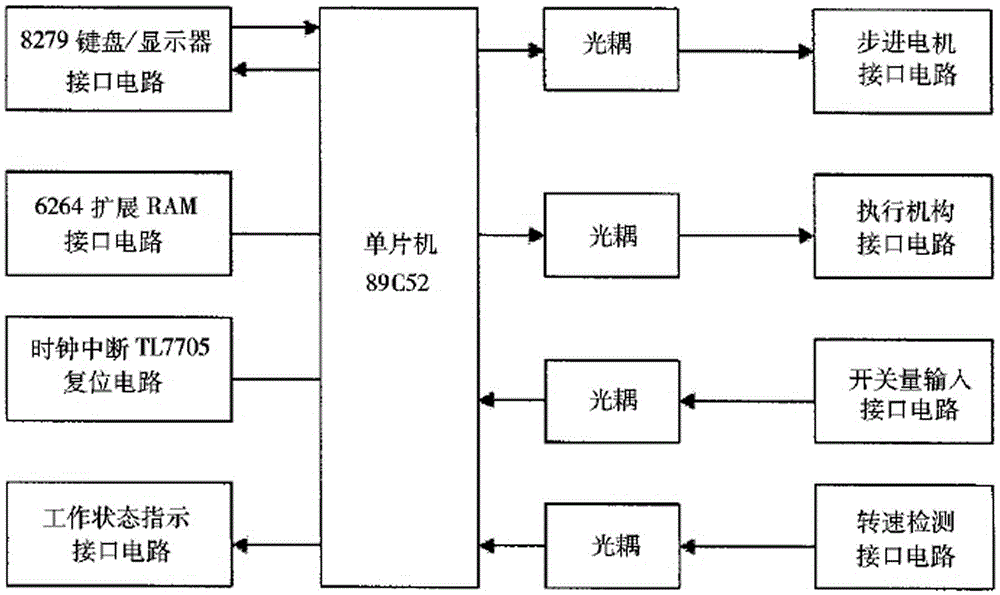

[0009] Such as figure 1 As shown, a winding machine control system, including microprocessor, display, 6264 extended RAM interface circuit, clock terminal TL7705 reset circuit, working status indication interface circuit, stepper motor interface circuit, actuator interface circuit, switch input The interface circuit and the rotating speed detection interface circuit are characterized in that: the display is connected to the output port of the single-chip microcomputer through the display interface circuit, the 6264 expansion RAM interface circuit, the clock terminal TL7705 reset circuit, and the working state indication interface circuit are connected to the state control port of the microprocessor, and the single-chip microcomputer The output port is connected to the interface circuit of the stepping motor and the interface circuit of the actuator through the optocoupler, and the interface circuit of the switch value input and the interface circuit of the speed detection are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com