Hypersonic speed propulsion wind tunnel control system based on PLC

A hypersonic and operation control technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of scattered control parts, high risk, and large number of detection signals, so as to simplify the structure and improve monitoring management level, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

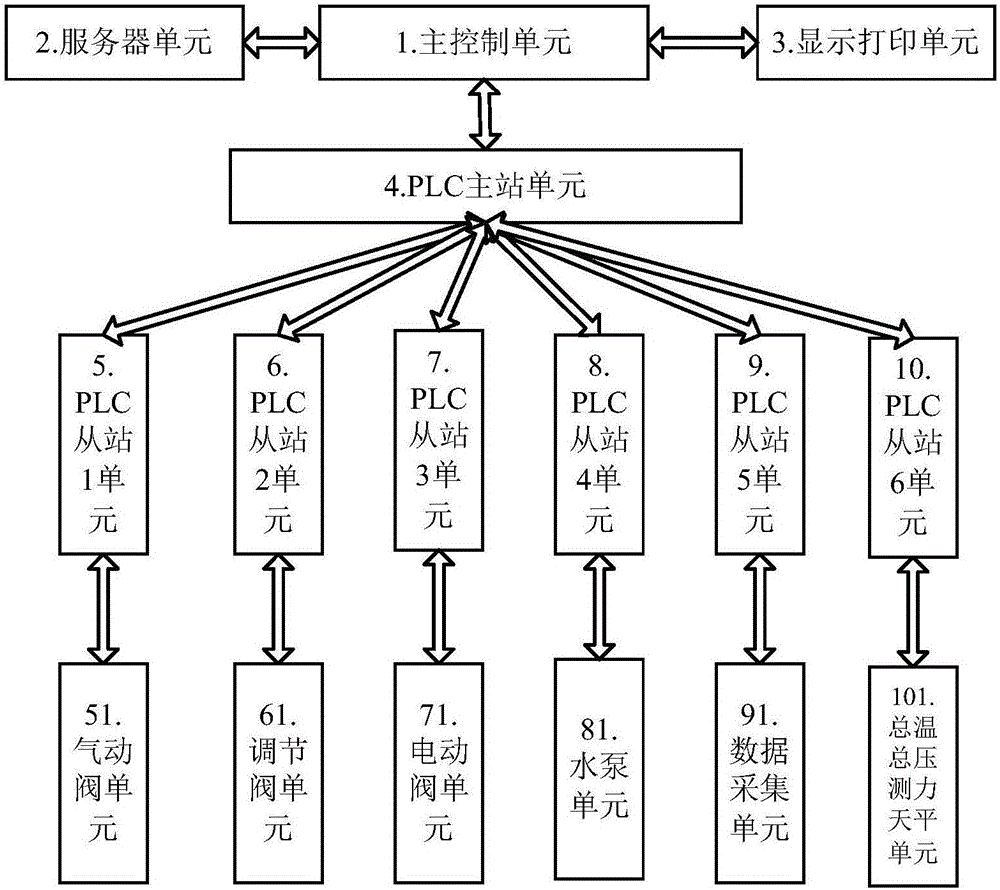

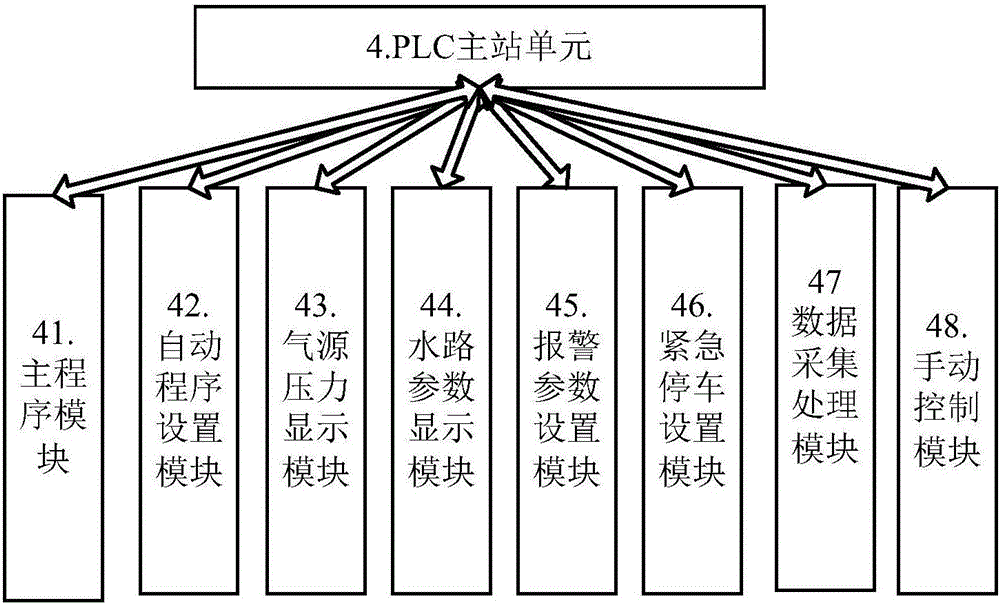

[0027] Example 1: see figure 1 , figure 2 , A hypersonic operation control system, including: main control unit 1, server unit 2, display printing unit 3, PLC master unit 4, PLC slave unit 1 unit 5, PLC slave station 2 unit 6, PLC slave station 3 unit 7, PLC slave station 4 unit 8, PLC slave station 5 unit 9, PLC slave station 6 unit 10, pneumatic valve unit 51, regulating valve unit 61, electric valve unit 71, water pump unit 81, data acquisition unit 91, total temperature Pressure sensing unit 101;

[0028] The main control unit 1 uses an industrial computer as a carrier, adopts WinCC configuration software to control the field equipment by man-machine interaction, and performs control program design through step7; the main control unit 1 is used for the compilation of control programs and remote field equipment Control and operation, data acquisition, display and transmission, as well as the downloading and debugging of PLC programs; the main control unit 1 and the PLC main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com