Product dimension sub-pixel measurement method under industrial microscale motion blurred imaging condition

A technology for motion blur and imaging conditions, applied in measuring devices, image enhancement, image analysis, etc., can solve problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

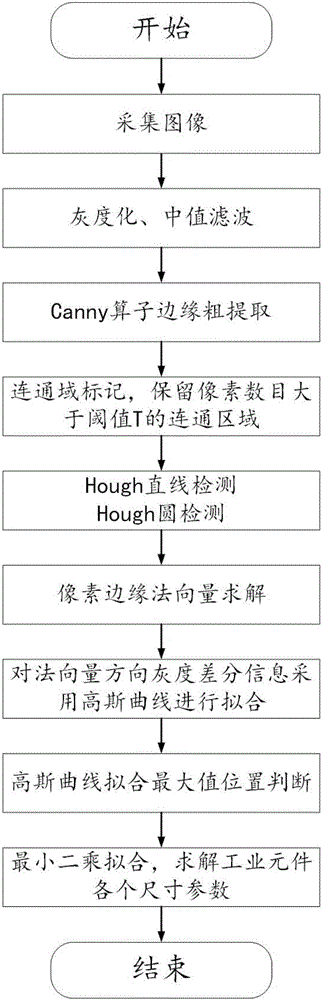

[0043] Embodiment 1: Combining Figure 1 to Figure 5 Describe this embodiment,

[0044]A sub-pixel measurement method of product size under the condition of industrial small-scale motion blur imaging, comprising the following steps:

[0045] Step 1: Perform grayscale and median filter processing on the industrial component image collected by the industrial camera to obtain the original grayscale image;

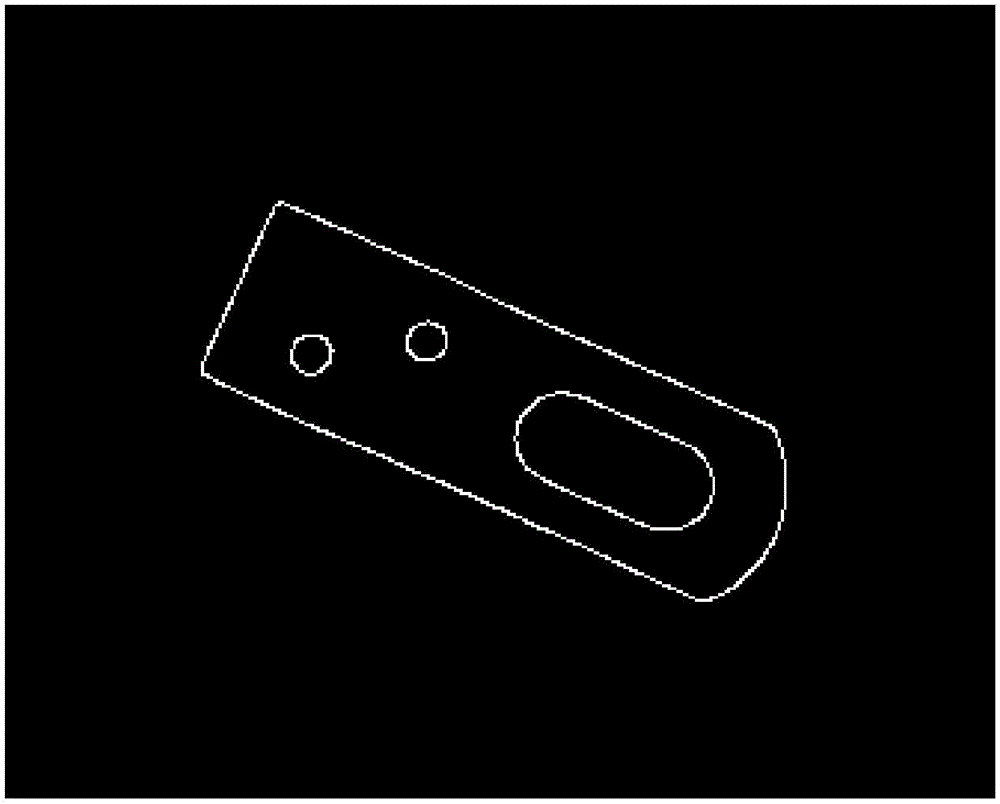

[0046] Step 2: For the original grayscale image, use the Canny operator to perform rough edge extraction to determine the edge position; perform local connected domain processing on the extracted edge pixels to obtain a complete edge binary image;

[0047] Step 3: Marking the connected domain on the complete edge binary image, screening the marked connected area, and retaining the connected area where the number of pixels contained in the connected area is greater than the preset threshold T;

[0048] Step 4: For the complete edge binary image obtained in step 3 after filter...

specific Embodiment approach 2

[0053] Specific implementation mode 2: Combining Figure 2a and Figure 2b Describe this embodiment,

[0054] The specific steps of performing local connected domain processing on the extracted edge pixels to obtain a complete edge binary image described in step 2 of this embodiment are as follows:

[0055] Step 21: Traverse each pixel on the edge position obtained by the rough extraction of the Canny edge;

[0056] Step 22. For each pixel, take the pixel as the center, and select a neighborhood window with a size of 3x3;

[0057] Step 2 and 3: If the number of connected domains in the neighborhood window is greater than or equal to 2, fill pixels between these connected domains to form a complete connected domain; otherwise, do not perform any operation; finally get Complete edge binary image;

[0058] Among them, the connected domain refers to the set of pixels that satisfies the 8-connectivity between the pixel positions.

[0059] Other steps and parameters are the sam...

specific Embodiment approach 3

[0061] The specific steps of screening the marked connected regions described in step 3 of this embodiment and retaining the connected regions with the number of pixels contained in the connected regions greater than the preset threshold T are as follows:

[0062] Step 31: Mark the connected domain of the complete edge binary image, at this time each complete edge is regarded as a connected domain and assigned a unique number;

[0063] Step 32: Analyze each connected domain: determine whether the number of pixels contained in the connected domain is greater than a preset threshold T;

[0064] Step 33: If it is greater than the preset threshold T, keep the connected domain; otherwise, remove the connected domain.

[0065] Other steps and parameters are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com