Edge detection-based wall body crack identification method

A crack recognition and edge detection technology, applied in the field of digital image recognition, can solve the problems of large amount of calculation, poor real-time performance, difficult to remove dirt, poor adaptability of interference items, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

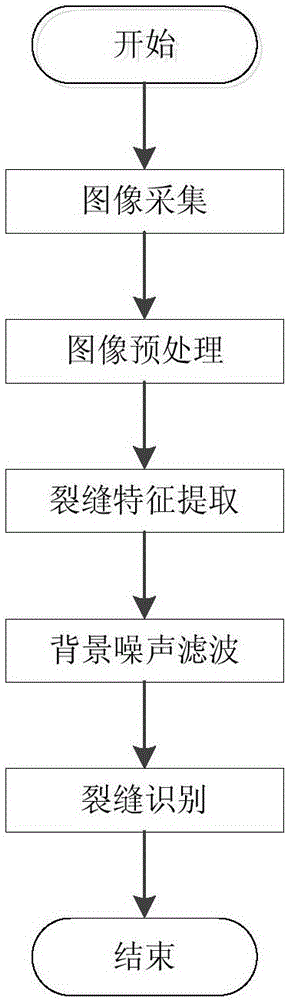

[0028] A method for identifying wall cracks based on edge detection, comprising:

[0029] Step 1, wall image acquisition;

[0030] The wall image acquisition described in step 1 is taken by a CCD lens or a digital camera. The present invention uses the visible light camera on the inspection robot to photograph the surface of the wall to obtain high-definition wall images.

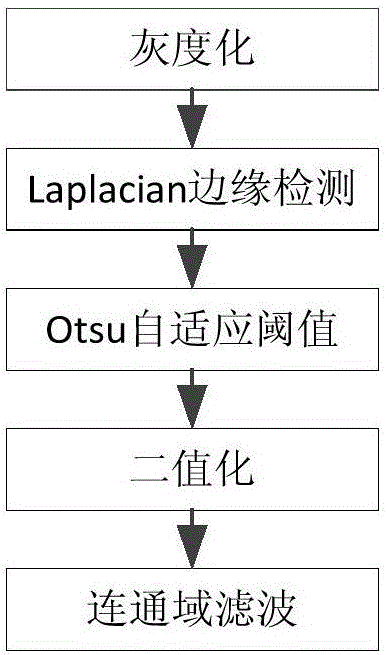

[0031] Step 2, image preprocessing;

[0032] The image preprocessing method described in step 2 is: first grayscale the collected original image, and use the gray average value of the OpenCV library to carry out weighted average of the red R, green G, and blue B channels of the original image, i.e. Gray=0.072169B+ 0.715160G+0.212671R to obtain a grayscale image; then Gaussian filtering is performed on the obtained grayscale image, and a 3×3 template is used for calculation to eliminate isolated points.

[0033] Step 3, crack edge extraction;

[0034] The method of crack edge extraction described in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com