Glass bottle defect detection system

A technology for defect detection and glass bottles, which is applied in the direction of optical testing for flaws/defects, measuring devices, and material analysis through optical means. It can solve problems that affect the appearance of products, do not propose specific solutions, and have low intelligence. Achieve the effect of eliminating background interference, improving convenience, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

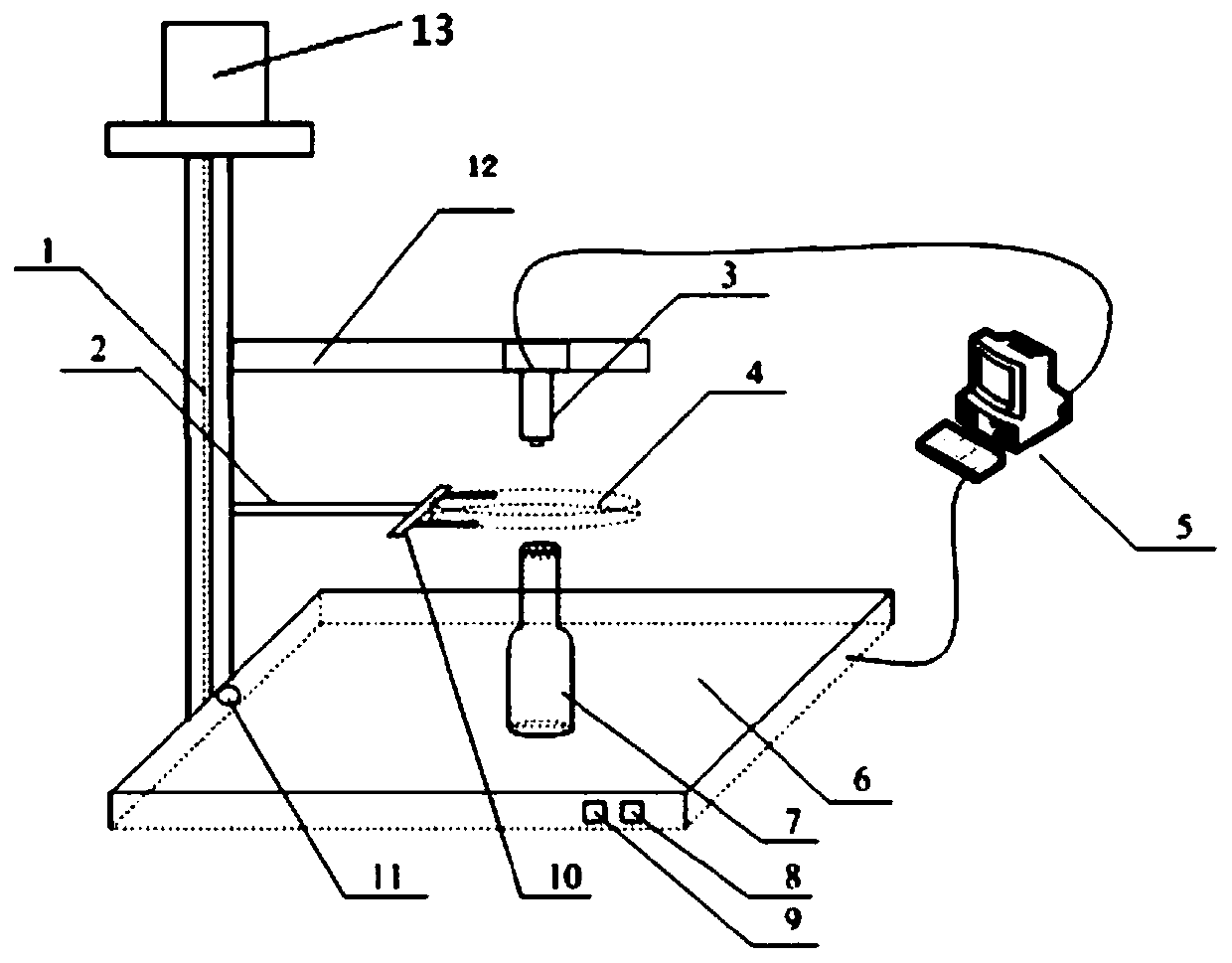

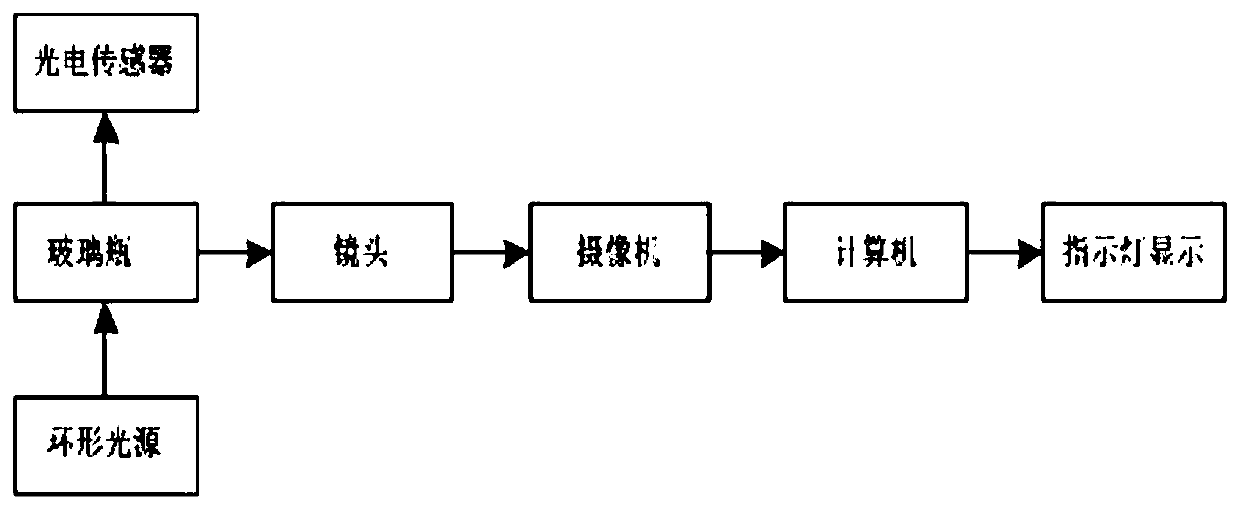

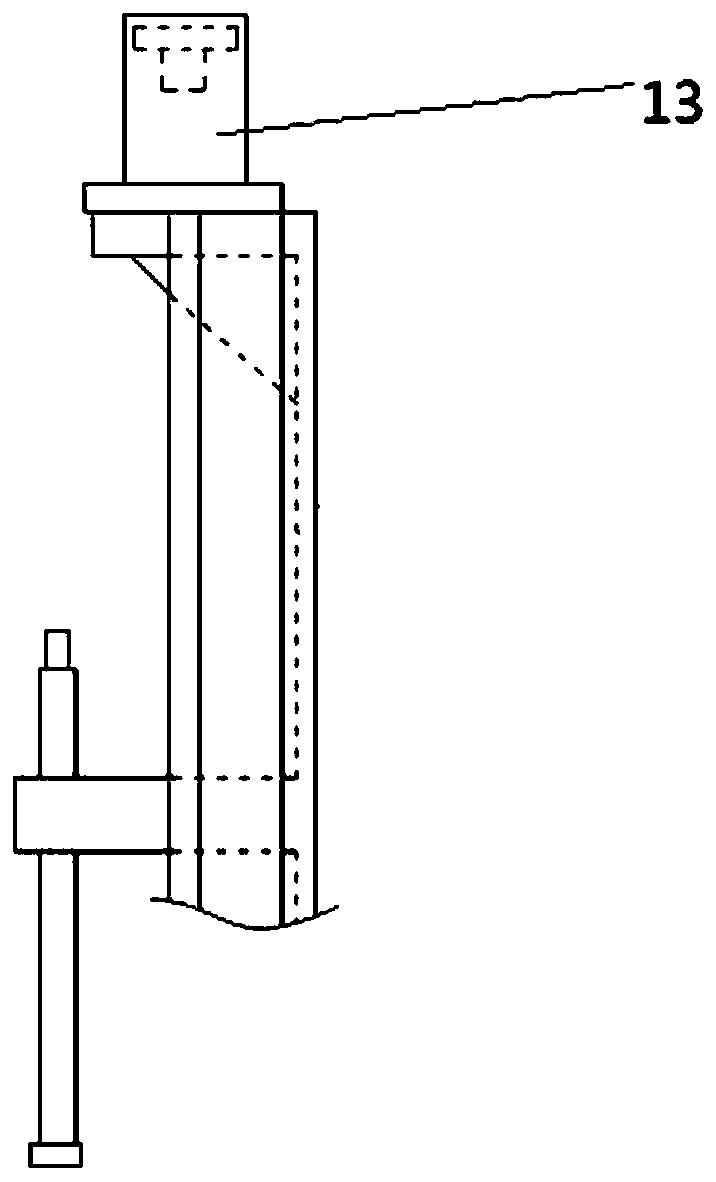

[0029] Such as figure 1 As shown, the present invention provides a glass bottle defect detection system, combined with figure 2 , the glass bottle defect detection system includes a carrying unit for carrying and rotating the glass bottle to be detected; a defect detection unit for determining whether there is a defect in the glass bottle; a judging unit for identifying and analyzing the defect information of the glass bottle The information processing unit is used for the analysis and processing of defect information; the adjustment support unit is used for adjusting the relative position between the defect detection unit and the glass bottle to be detected; the control unit is used for controlling the defect detection unit and the An adjustment support unit; the bearing unit is connected to the support adjustment unit, and the control unit is signal-connected to the defect detection unit, the adjustment support unit, the judgment unit and the information processing unit; wh...

Embodiment 2

[0033] Such as Figure 1-2 As shown, the present invention provides a glass bottle defect detection system, the glass bottle defect detection system includes a carrying unit for carrying and rotating the glass bottle to be detected; a defect detection unit for determining whether the glass bottle is defective; The unit is used to prompt whether there is a defect in the glass bottle to be detected; the judgment unit is used to identify and analyze the defect information of the glass bottle; the information processing unit is used to analyze and process the defect information; the adjustment support unit is used to adjust the defect information The relative position between the detection unit and the glass bottle to be detected; the control unit is used to control the defect detection unit and the adjustment support unit; the carrying unit is connected to the support adjustment unit, and the control unit is connected to the support adjustment unit The defect detection unit, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com