Nanometer zirconia base acetone sensitive material

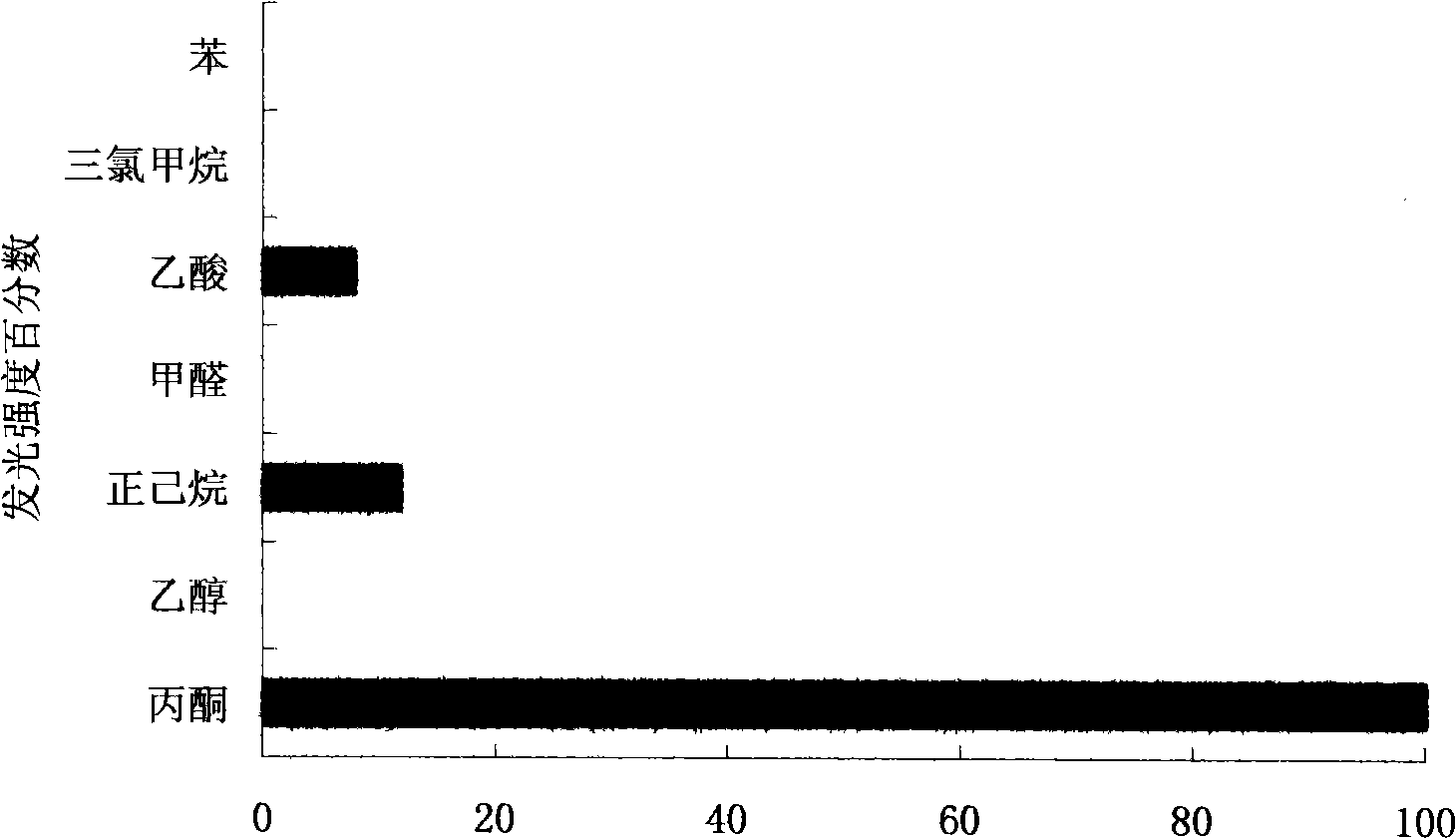

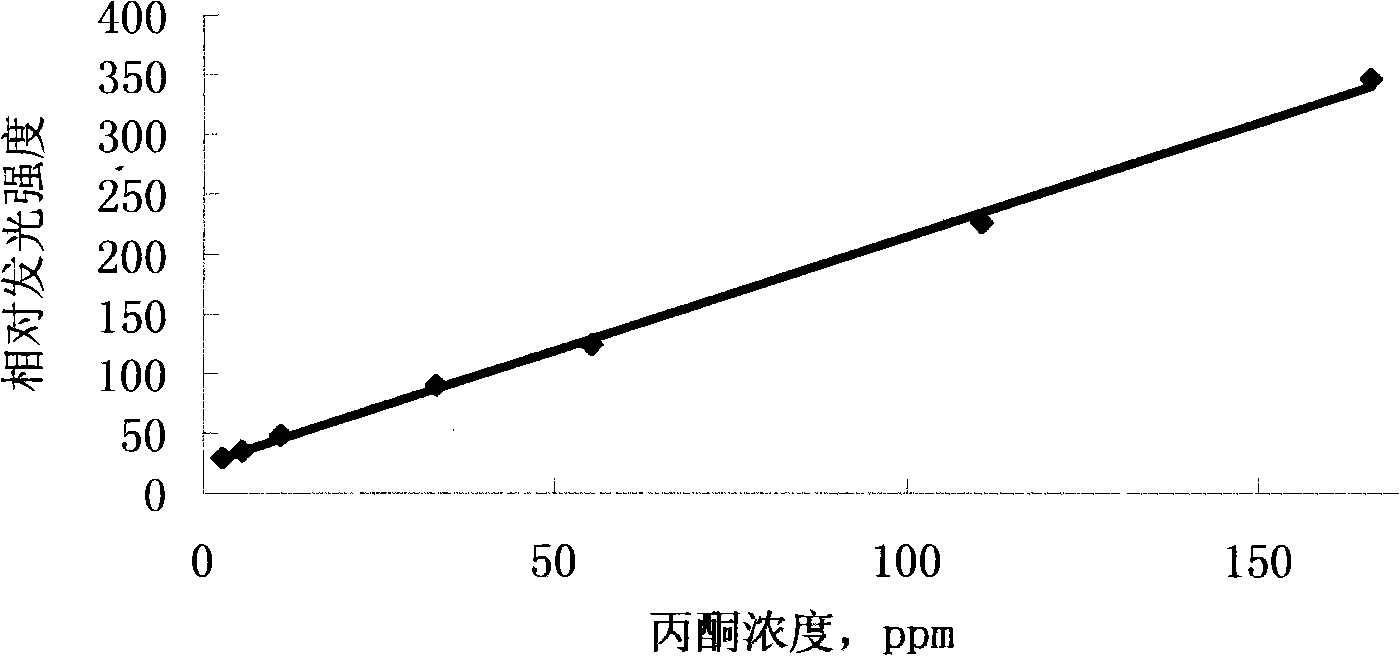

A zirconia-based acetone, sensitive material technology, applied in the direction of chemical reaction of materials for analysis, chemiluminescence/bioluminescence, etc., can solve problems such as interference, and achieve improved selectivity, real-time monitoring is beneficial, and response speed is fast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Take 20mL 0.1mol / LZr(NO 3 ) 4 ·3H 2 O, add 4mL Tween-80, and stir evenly in a sonicator. Add 20mL of 3mol / L ammonia water dropwise to form a precipitate. After precipitation, centrifuge for about 20 minutes, then dry in an oven at 110°C for 2 hours, then heat-treat at 600°C in an aerobic atmosphere for 3 hours, take it out and cool it, and grind it thoroughly to get zirconia nanopowder.

[0024] Weigh 1 part of zirconia nanopowder and 0.117 part of erbium oxide powder, put them in a container, add distilled water to stir into a thin paste, mix well, put them in a drying oven at 110°C for 2 hours, and place them in a muffle furnace Treat at 600°C for 3 hours, take it out and cool it down and grind it thoroughly. During heat treatment in the muffle furnace, do not close the door of the muffle furnace, and leave a gap in the door to ensure that there is sufficient oxygen in the furnace to remove residual organic matter in the material.

example 2

[0026] Take 20mL 0.1mol / LZr(NO 3 ) 4 ·3H 2 O, add 4mL Tween-80, and stir evenly in a sonicator. Add 20mL of 3mol / L ammonia water dropwise to form a precipitate. After precipitation, centrifuge for about 20 minutes, then dry in an oven at 110°C for 2 hours, then heat-treat at 600°C in an aerobic atmosphere for 3 hours, take it out and cool it, and grind it thoroughly to get zirconia nanopowder.

[0027] Weigh 1 part of zirconia nanopowder and 1.55 parts of erbium oxide powder, put them in a container, add distilled water and stir into a thin paste, mix well and put them in a drying oven at 110°C for 2 hours, then dry in an aerobic atmosphere Heat treatment in a muffle furnace at 550°C for 3 hours, take it out and cool it down and grind it thoroughly. During heat treatment in the muffle furnace, do not close the door of the muffle furnace, and leave a gap in the door to ensure that there is sufficient oxygen in the furnace to remove residual organic matter in the material. ...

example 3

[0029] Take 20mL 0.1mol / LZr(NO 3 ) 4 ·3H 2 O, add 4mL Tween-80, and stir evenly in a sonicator. Add 20mL of 3mol / L ammonia water dropwise to form a precipitate. After precipitation, centrifuge for about 20 minutes, then dry in an oven at 110°C for 2 hours, then heat-treat at 600°C in an aerobic atmosphere for 3 hours, take it out and cool it, and grind it thoroughly to get zirconia nanopowder.

[0030] Weigh 1 part of zirconia nanopowder and 0.02 part of dysprosium oxide powder, put them in a container, add distilled water to stir into a thin paste, mix well, put them in a drying oven at 110°C for 2 hours, and put them in a muffle furnace Treat at 650°C for 2 hours, take it out and cool it, then grind it thoroughly. During heat treatment in the muffle furnace, do not close the door of the muffle furnace, and leave a gap in the door to ensure that there is sufficient oxygen in the furnace to remove residual organic matter in the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com