Gasket size detection system and method based on machine vision, processing terminal and medium

A dimensional inspection and machine vision technology, applied in the field of gasket quality inspection and visual optical design, can solve the problems of inaccurate measurement, product rejection, and high maintenance costs, and achieve the effect of automatic full inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

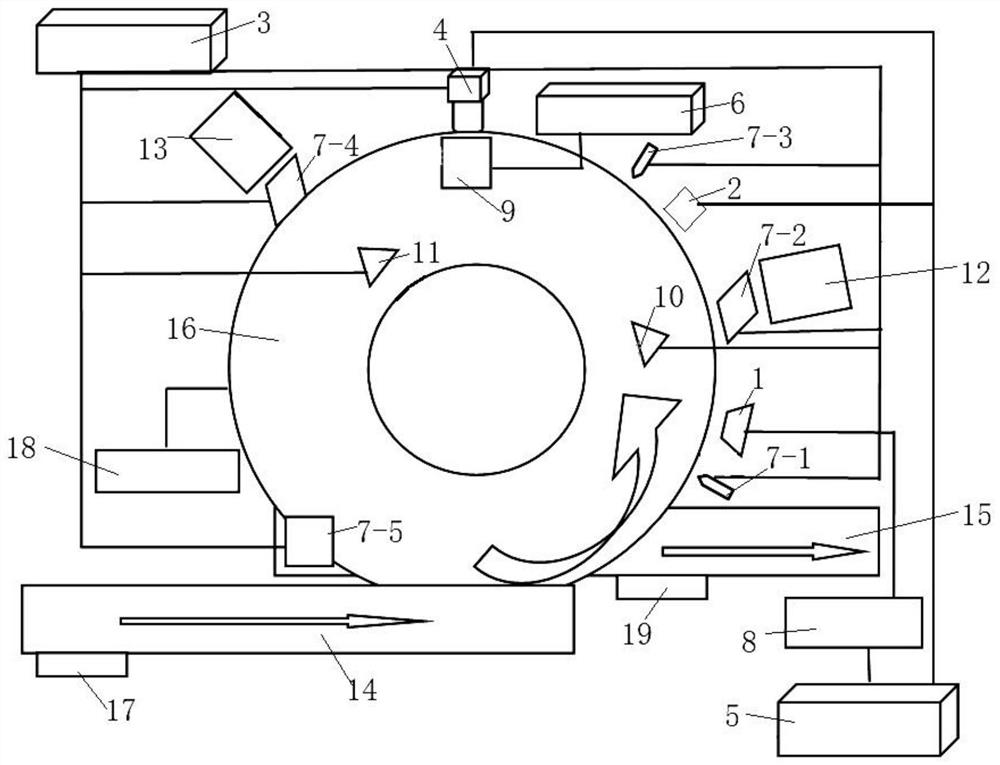

[0113] Such as figure 1 As shown, the visual inspection system of the present invention includes two detection stations (the point-to-shot laser detection station 1 and the camera detection station 2), two rejecting stations (the point-to-shot laser detection and removal station 12 and the camera Detection and rejection station 13), three transmission mechanisms (feeding transmission mechanism 14, unloading transmission mechanism 15, glass turntable transmission mechanism 16). It also includes sensors. There are 5 types of sensors, which are arranged in sequence on the transport direction of the workpiece to be detected; they are respectively used for the laser trigger sensor 7-1 of the shooting point, the laser detection sensor 7-2 of the laser removal point of the shooting point, and the camera triggering sensor. Sensor 7-3, camera rejecting station detection sensor 7-4 and qualified product blanking detection sensor 7-5; the sensors are all photoelectric sensors.

[0114]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com