Integrated double-layer vertically wound inductor and manufacturing method thereof

A manufacturing method and inductor technology, applied in the field of inductors, can solve the problems of open circuit or short circuit, bruised coil, virtual welding and other problems of finished products, and achieve the effect of enhancing load capacity guarantee, ensuring connection reliability, and improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

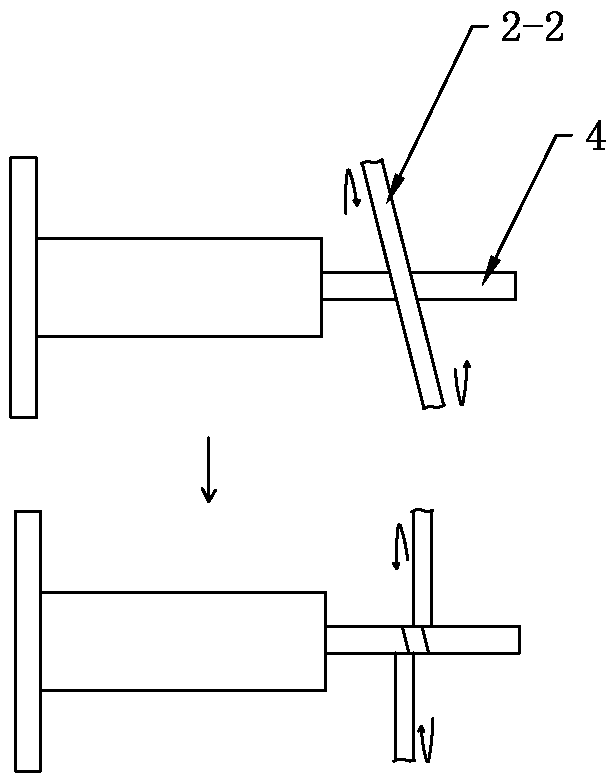

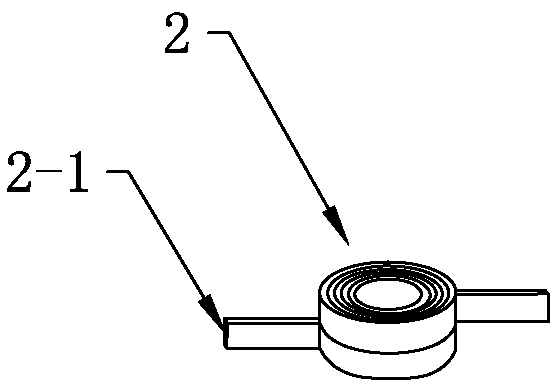

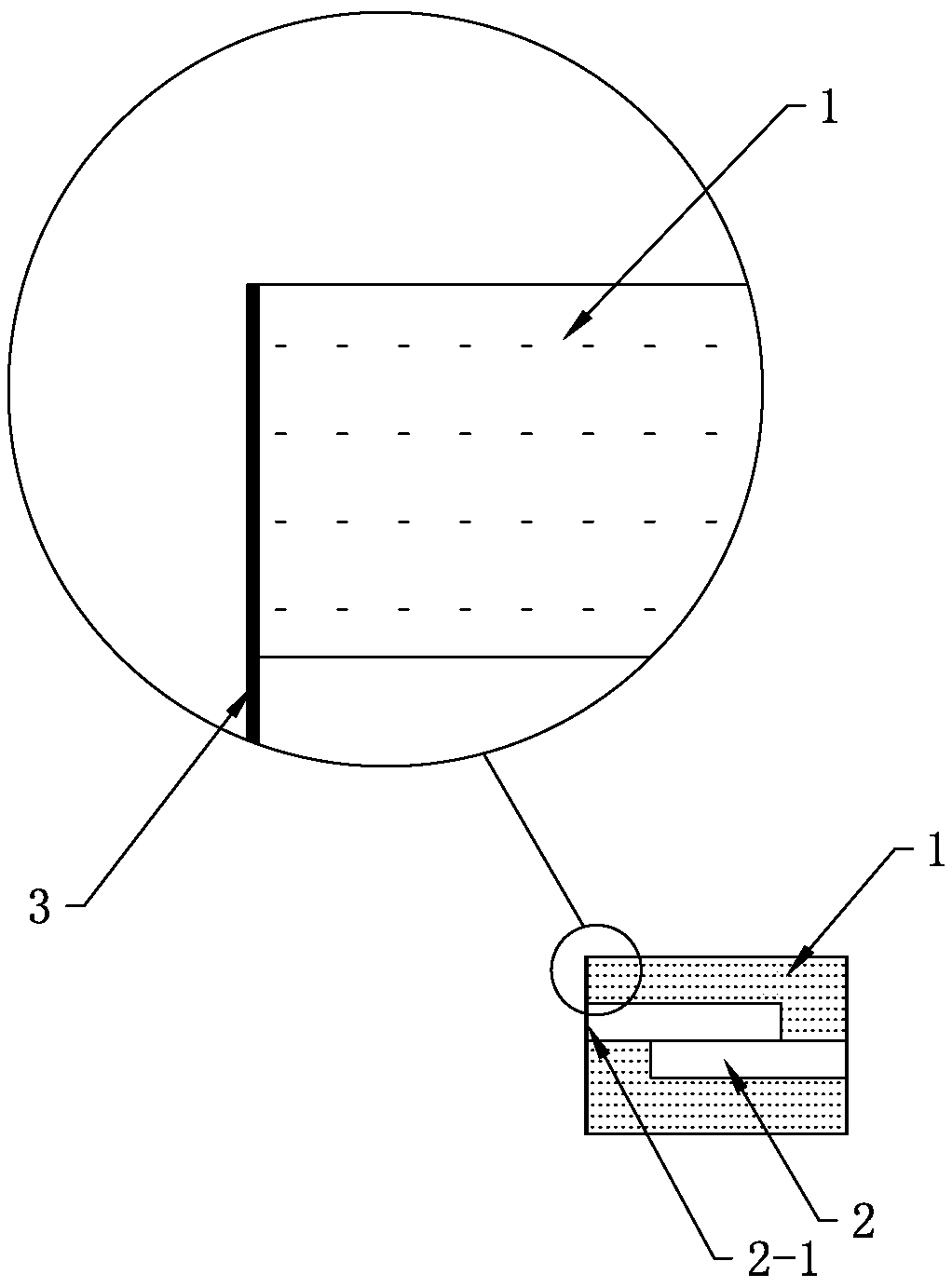

[0045] see Figure 1 to Figure 3 The integrated double-layer vertically wound inductor of this embodiment includes a magnetic body 1, an air-core coil 2 and a covered electrode 3. The magnetic body 1 is pressed from magnetic powder, and the air-core coil 2 is buried in the magnetic powder and passed through high The integral molding structure of the air-core coil 2 and the magnetic body 1 is obtained by pressing, the coil end 2-1 of the air-core coil 2 is exposed to the magnetic body 1, wherein the air-core coil 2 is provided with two layers of coils, and the winding directions of the upper and lower layers of coils are consistent and The upper and lower coils have the same number of turns. In this embodiment, the coil shape of the air-core coil 2 is circular. The air-core coil 2 has a layer of coils on the upper and lower layers, and the winding direction of the two-layer coils is exactly the same as the number of turns. This type of air-core coil 2 has a tighter structure, h...

Embodiment 2

[0066] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The coil shape of the air core coil 2 in this embodiment is ellipse.

Embodiment 3

[0068] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. In the manufacturing method of the integrated double-layer vertical wound inductor, the first stage of step (2) was sintered at 70°C for 30 minutes, the second stage was heated at 115°C for 90 minutes, and the third stage was sintered at 155°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com