Motor commutator finish machining workbench

A commutator and workbench technology, applied in the field of mechanical equipment, can solve the problems that the quality of the commutator cannot be uniform and stable, the debris cannot be blown away in time, and the labor intensity of the workers is high, so as to achieve simple structure, stable and convenient use Reliable, less labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

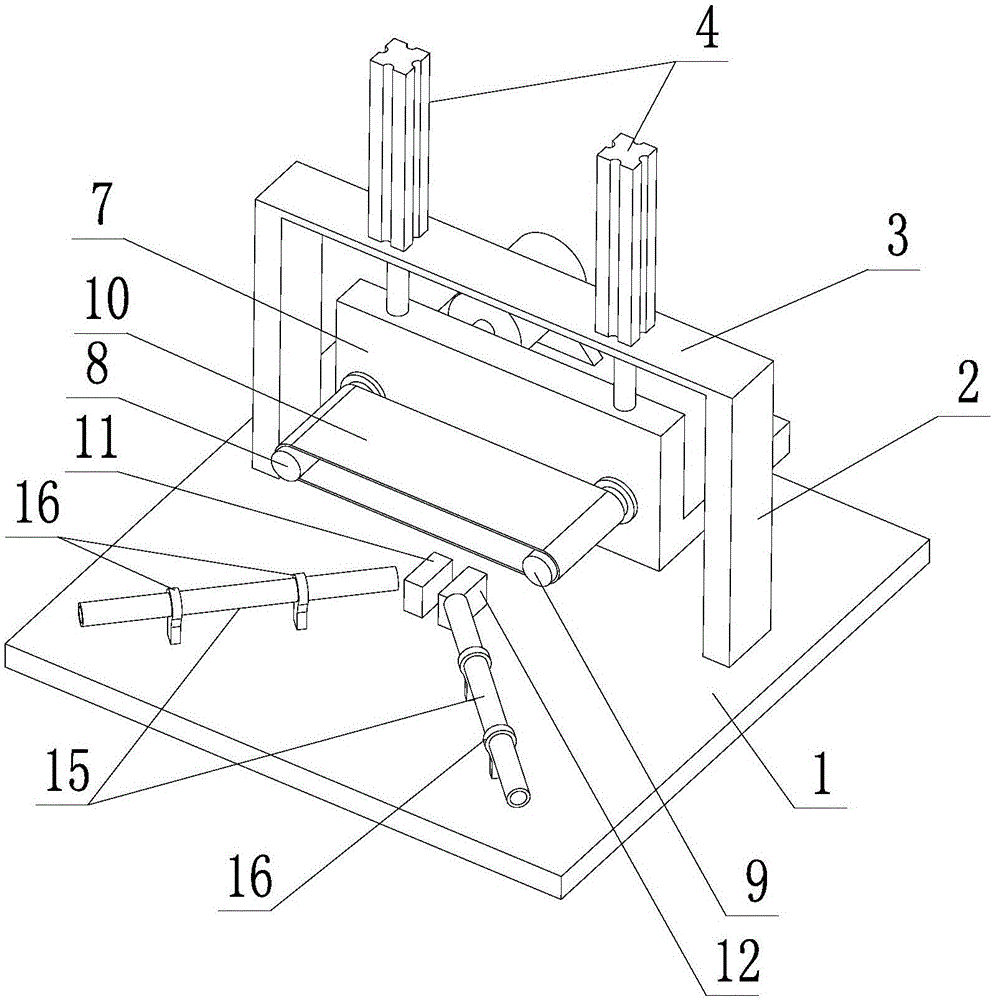

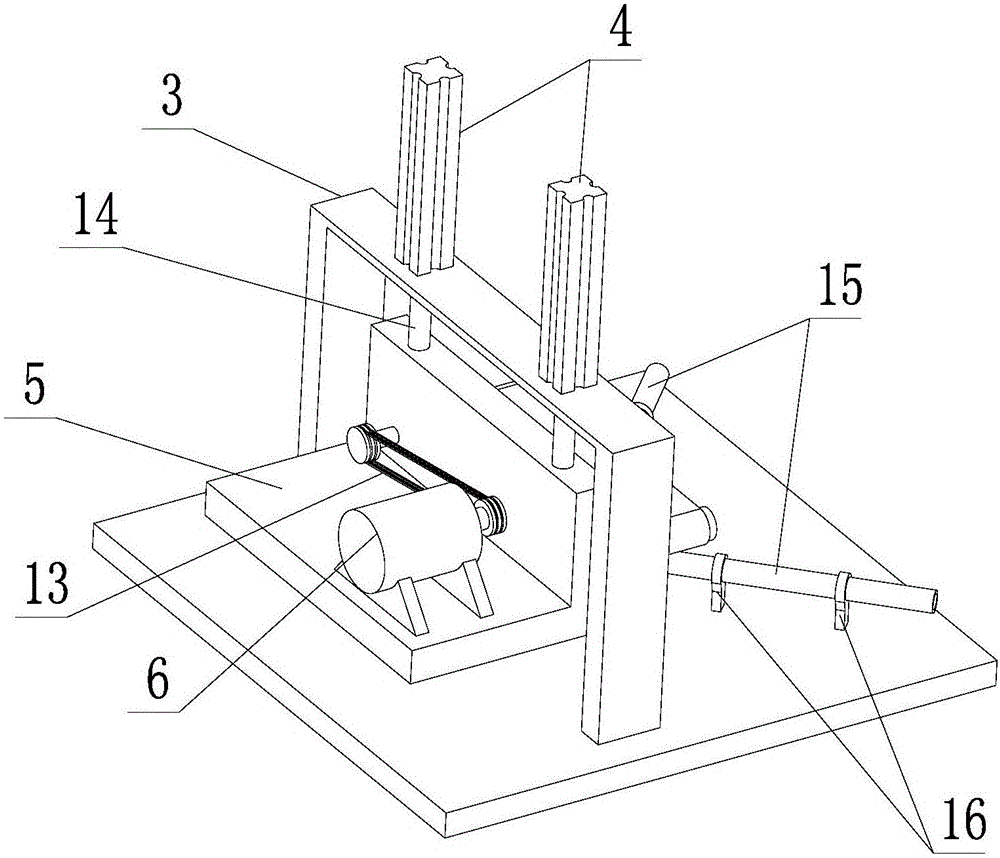

[0013] Specific examples: please refer to figure 1 with figure 2 , A commutator finishing workbench for a motor, comprising an operation table 1, a cylinder fixing column 2, a cylinder 4, a motor fixing plate 5 and a blower pipe 15. The bottom of the cylinder fixing column 2 is fixed on the operation table 1, so A cylinder fixing plate 3 is fixed on the top of the cylinder fixing column 2, the cylinder 4 is fixed on the cylinder fixing plate 3, the cylinder mandrel 14 passes through the cylinder fixing plate 3, the top of the cylinder mandrel 14 is fixed There is a roller fixing plate 7, the motor fixing plate 5 is fixed on the bottom of the roller fixing plate 7, a motor 6 is fixed on the motor fixing plate 5, and a driven roller 8 is provided on the roller fixing plate 7 And the driving roller 9, the motor 6 drives the driving roller 9 through the transmission belt 13, the driven roller 8 and the driving roller 9 are provided with a friction belt 10, and a product fixing belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com