led linear constant power drive circuit

A drive circuit and constant power technology, which is applied in the field of LED linear constant power drive circuit, can solve the problems of inconsistent average current value of LED lights, inability to achieve constant power output, and light strings that cannot be turned on and illuminated, so as to achieve high utilization of the light strings , good circuit effect and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

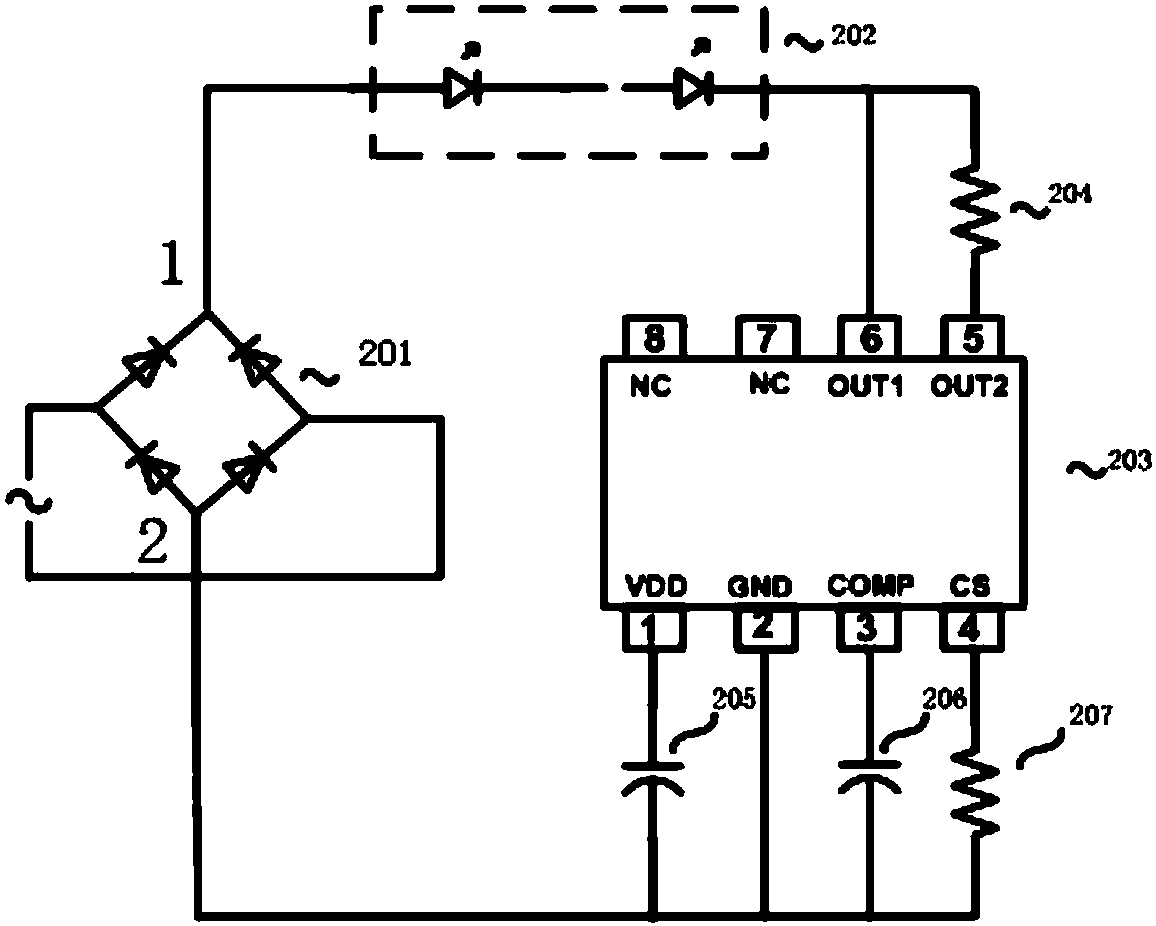

[0022] like figure 2 Shown is the LED linear constant power drive circuit described in the present invention, including AC power supply, rectifier bridge 201, LED light string 202, main control chip 203, voltage regulating resistor 204, voltage stabilizing capacitor 205, compensation capacitor 206 and current regulating resistor 207. The input terminal of the rectifier bridge 201 is connected to the AC power supply, and the output terminal 1 of the rectifier bridge 201 is connected to the positive terminal of the LED light string 202; connected; the negative end of the voltage regulating resistor 204 is connected to the OUT2 port of the main control chip 203; the positive end of the voltage stabilizing capacitor 205 is connected to the VDD port of the main control chip 203, and the negative end of the voltage stabilizing cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com