Method for manufacturing image display device and image display device

A technology of an image display device and a manufacturing method, applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of liquid crystal cell gap change, ripple, visibility problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

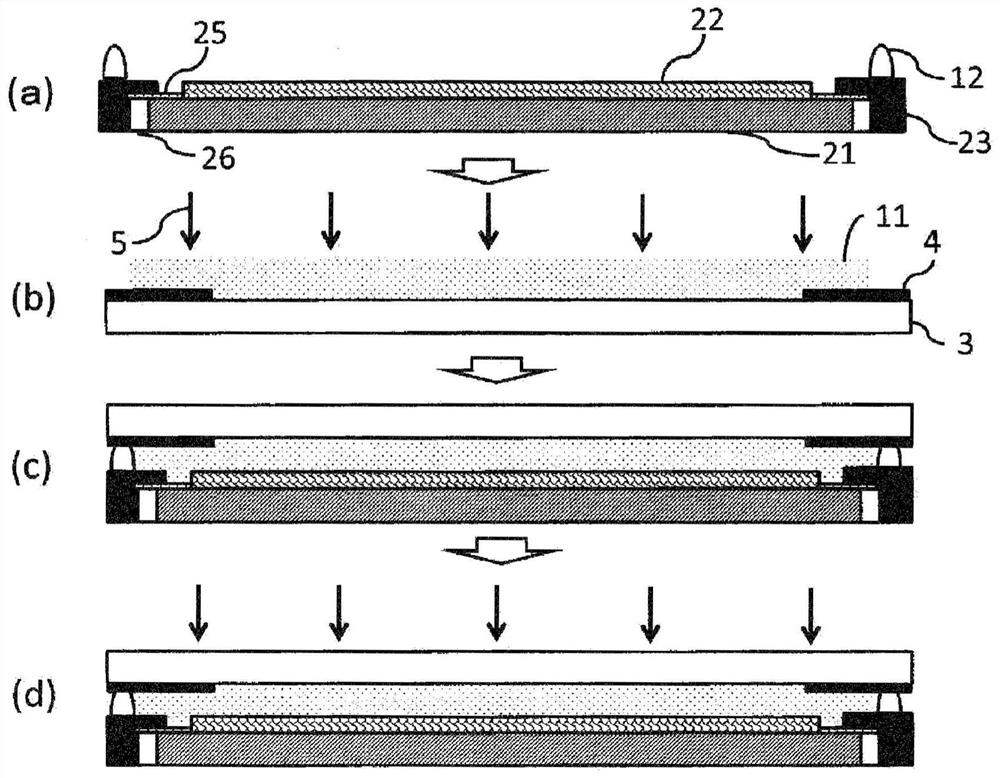

[0056] figure 1 It is a process drawing which shows 1st Embodiment of the manufacturing process of the optical member of this invention.

[0057] This method is a method of obtaining an optical member (image display device) by bonding the liquid crystal display unit 1 and the protective plate 2 together.

[0058] The liquid crystal display unit 1 is a liquid crystal display unit in which a liquid crystal material is sealed between a pair of substrates on which electrodes are formed, and includes a polarizing plate, a driving circuit, a signal input cable, and a backlight unit.

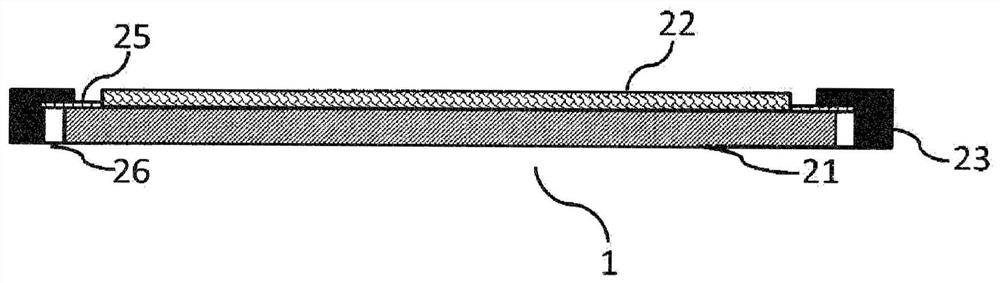

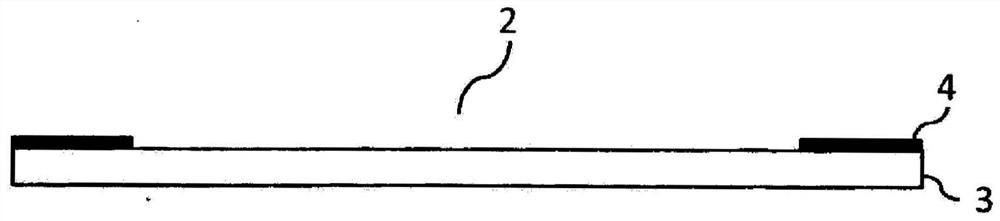

[0059] figure 2 It is a cross-sectional view showing a main part of an example of the liquid crystal display unit 1 . Such as figure 2 As shown, this liquid crystal display unit 1 has a configuration in which a polarizing plate 22 is disposed on a liquid crystal display cell 21 , and a sealing body 23 is disposed on the liquid crystal display cell 21 so as to surround the polarizing plate 22 . He...

no. 2 approach

[0155] The optical member of the present invention can also be produced by the second embodiment modified as follows from the first embodiment.

[0156] [Process A]

[0157] First, if Figure 5 As shown in (a), the 2nd curable resin composition 12 containing a (meth)acrylate (A) and a photoinitiator (B) is apply|coated on the surface in which the light-shielding part 4 was formed on the guard plate 2.

[0158] [Process B]

[0159] Then, if Figure 5 As shown in (b), the first curable resin composition 11 is coated on the surface of the protective plate 2 on which the light-shielding portion 4 is formed, and then the obtained coating film is irradiated with ultraviolet rays 5 to obtain a The cured product layer exists in the cured portion on the lower side of the layer (the transparent substrate side viewed from the curable resin composition) and the uncured portion on the upper side of the coating layer (the side opposite to the transparent substrate side).

[0160] At this ...

no. 3 approach

[0168] The optical member of the present invention can also be produced by the third embodiment modified as follows on the basis of the first embodiment and the second embodiment.

[0169] [Process A]

[0170] First, if Figure 6 As shown in (a), the second curable resin composition 12 containing (meth)acrylate (A) and photopolymerization initiator (B) is coated on the display surface of the liquid crystal display unit 1 and the protective plate 2. On the surface of the face of the light shielding part 4 .

[0171] [Process B]

[0172] Then, if Figure 6 As shown in (b), the first curable resin composition 11 containing (meth)acrylate (A) and photopolymerization initiator (B) is coated on the display surface of the liquid crystal display unit 1 and the protective plate 2. On the surface of the face of the light shielding part 4 .

[0173] The obtained coating film was irradiated with ultraviolet rays 5 to obtain a cured portion existing on the lower side of the coating fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com