Formula and preparation process of self-stretching high-smoothness transparent glaze slip

A transparent glaze, smoothing technology, applied in the field of transparent glaze paste, which can solve the problems of low gloss, high porosity and uneven glaze surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

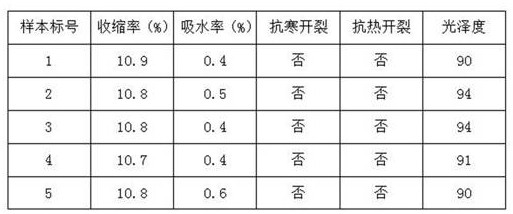

Examples

Embodiment 1

[0017] A self-stretching, high-smooth, transparent glaze formulation made of the following components by weight percentage:

[0018] Quartz: 10 parts; potassium feldspar powder: 10 parts; anorthite: 10 parts; clay: 5 parts; talc: 5 parts; double fly powder: 5 parts; alumina: 10 parts; silicon oxide: 5 parts; 4 parts; barium carbonate: 8 parts; frit: 20 parts;

[0019] The raw material composition of the frit is calculated by weight percentage: calcium oxide: 60 parts; calcium borate: 20 parts; borax: 20 parts.

[0020] The specific steps of the manufacturing process for preparing glazed tiles using self-stretching, high-smooth transparent glaze paste formula are as follows:

[0021] (1) Accurately weigh the raw materials according to the glaze formula, then ball mill the raw materials, and pass through a 325 mesh screen after ball milling to improve the uniformity of the particles;

[0022] (2) Then mix according to the ratio of ingredients: water = 2:1.5, mix these raw mate...

Embodiment 2

[0026] A self-stretching, high-smooth, transparent glaze formulation made of the following components by weight percentage:

[0027] Quartz: 15 parts; potassium feldspar powder: 5 parts; anorthite: 10 parts; clay: 5 parts; 5 parts; barium carbonate: 10 parts; frit: 20 parts;

[0028] The raw material composition of the frit is calculated by weight percentage: calcium oxide: 70 parts; calcium borate: 15 parts; borax: 15 parts.

[0029] The specific steps of the manufacturing process of preparing glazed tiles by using the self-stretching, high-smooth transparent glaze slurry formula are as follows:

[0030] (1) Accurately weigh the raw materials according to the glaze formula, then ball mill the raw materials, and pass through a 325 mesh screen after ball milling to improve the uniformity of the particles;

[0031] (2) Then mix according to the ratio of ingredients: water = 2:1, mix these raw materials and wet ball mill to make glaze slurry, adjust the performance to a specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com