Foam cleaning disinfectant containing peracetic acid and application of foam cleaning disinfectant

A peracetic acid and disinfectant technology, applied in the direction of disinfectant, application, biocide, etc., can solve the problems of high operation requirements, low utilization rate of disinfectant solution, strong corrosion of sodium hypochlorite, etc., achieve high-efficiency disinfection effect and save disinfectant The effect of dosage and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

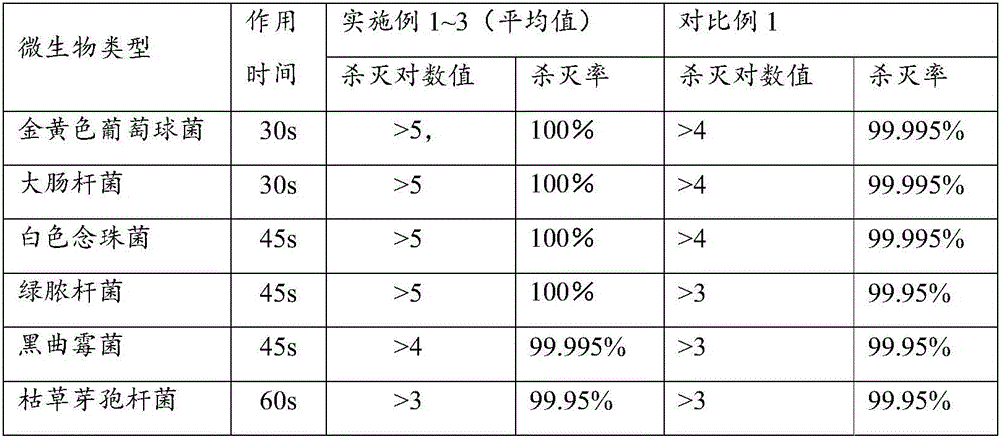

Examples

Embodiment 1

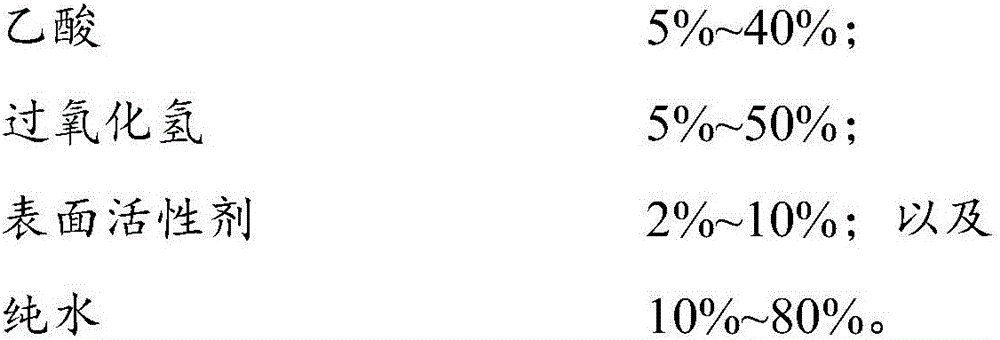

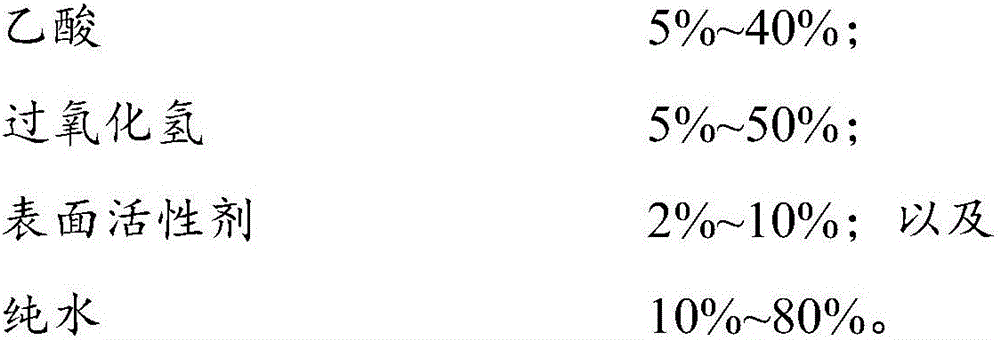

[0038] A peracetic acid foam cleaning and disinfecting agent is composed of the following raw materials by mass percentage, and the preparation process is as follows:

[0039] Add 7 parts of water, 1 part of acetic acid, and 1 part of hydrogen peroxide into a plastic bottle, stir and mix evenly; add 0.02 parts of sodium cetylsulfonate, and add N-dimethyl-hexadecylamine oxide to a content of 0.2 part, add 0.02 part of EDTA; add the remainder of water after stirring. The product is allowed to stand at room temperature for 1-7 days, and the concentration of peracetic acid is determined to be 0.28% by using quick test paper.

Embodiment 2

[0041] A peracetic acid foam cleaning and disinfecting agent is composed of the following raw materials by mass percentage, and the preparation process is as follows:

[0042] Add 5 parts of water, 3.5 parts of acetic acid, and 2 parts of hydrogen peroxide into a plastic bottle, stir and mix evenly; add 0.05 parts of sodium xylenesulfonate, and add 0.3 parts of N-dimethyl-hexadecylamine oxide, Add 0.02 parts of NTA; add the remainder of water after stirring. The product is allowed to stand at room temperature for 1-7 days, and the concentration of peracetic acid is determined to be 3.5% by using quick test paper.

Embodiment 3

[0044] A peracetic acid foam cleaning and disinfecting agent is composed of the following raw materials by mass percentage, and the preparation process is as follows:

[0045] Add 3 parts of water, 4 parts of acetic acid, and 2.5 parts of hydrogen peroxide into a plastic bottle, stir and mix evenly; add 0.05 parts of sodium xylene sulfonate, and add 0.4 parts of N-dimethyl-hexadecylamine oxide, Add 0.04 parts of EDTA; add the remainder of water after stirring. The product is allowed to stand at room temperature for 1-7 days, and the concentration of peracetic acid is determined to be 5.4% by using quick test paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com