Feed conditioning device

A conditioning and feed technology, applied in the direction of feed, food science, application, etc., can solve the problems of feed clogging pores, unfavorable heat utilization, large energy consumption, etc., to promote heat, strengthen shearing, and prolong conditioning time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

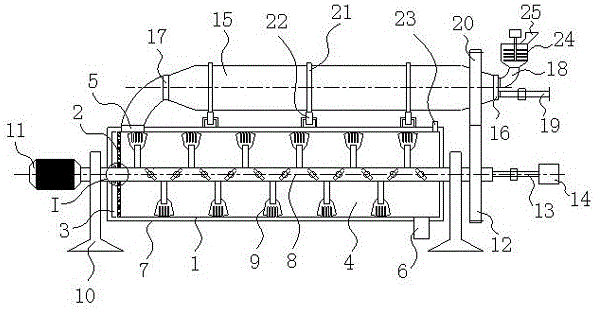

[0020] Attached below figure 1 ~ 7 further elaborate the present invention.

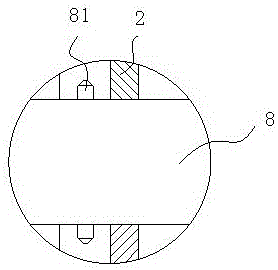

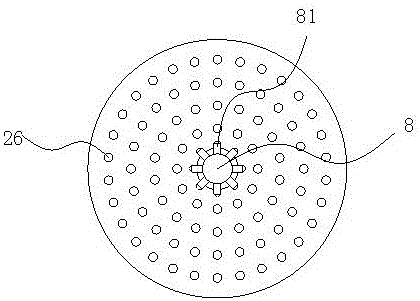

[0021] A feed conditioning device, comprising a cylindrical conditioner 1, inside the conditioner 1 there is a circular gas distribution plate 2, in order to make the distribution of superheated steam more uniform, the gas distribution plate 2 is uniformly provided with gas The distribution hole 26 and the gas distribution plate 2 are fixedly connected to the inner wall of the shell of the conditioner 1. The gas distribution plate 2 divides the interior of the conditioner 1 into a steam chamber 3 and a conditioning chamber 4. The first feed port 5 communicating with the interior of the quality chamber 4, the lower part of the other end of the shell 4 is provided with the first discharge port 6 communicating with the interior of the tempering chamber 4, and the shell of the conditioner 1 is covered with a layer of insulation clip The sleeve 7 reduces the heat loss of the conditioner 1 caused by the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com