Automatic steam heater and control method thereof

A heating machine and steam technology, which is applied to steam cooking utensils, cooking utensils, household utensils, etc., can solve the problems of low efficiency, uniform mixing, uneven heating, etc., and achieve the effects of improving efficiency, heating uniformly, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

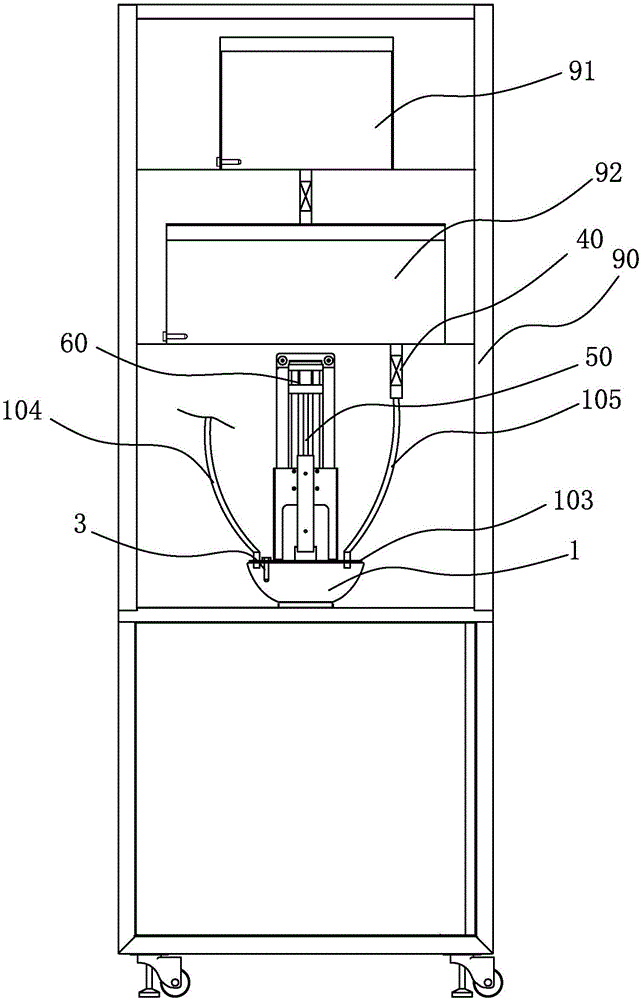

[0039] Such as Figure 1~6 In the specific embodiment shown, an automatic steam heating machine provided by this embodiment can be used in heating noodles, and can also be used in the process of heating other foods. The steam heating method is used to automatically heat noodles, reducing The operator's operating intensity reduces labor costs, improves efficiency, and heats evenly.

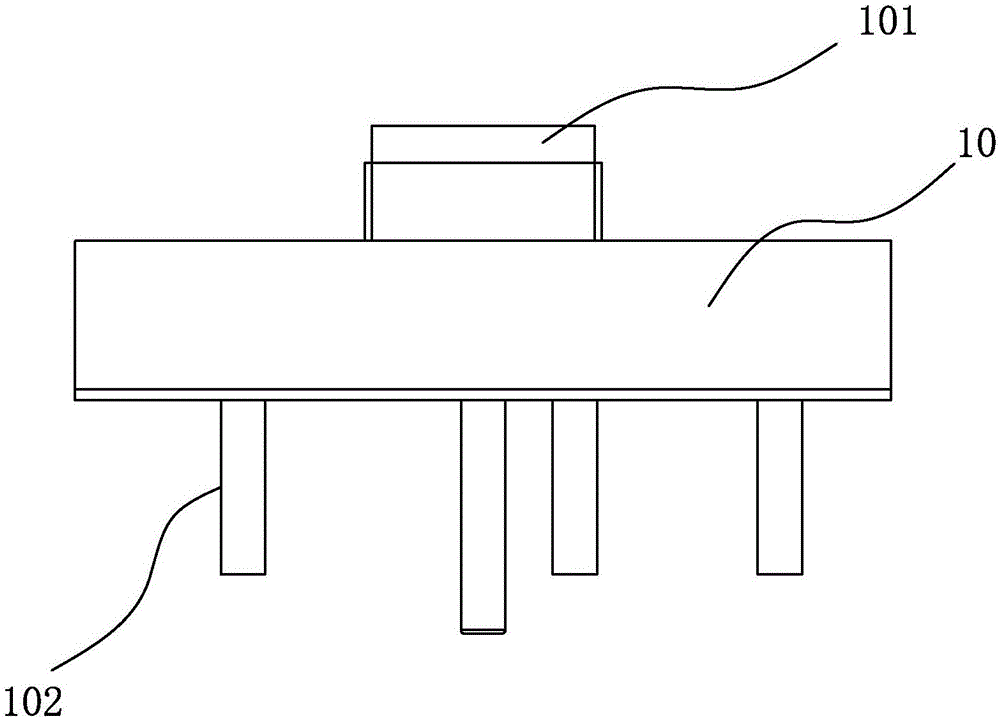

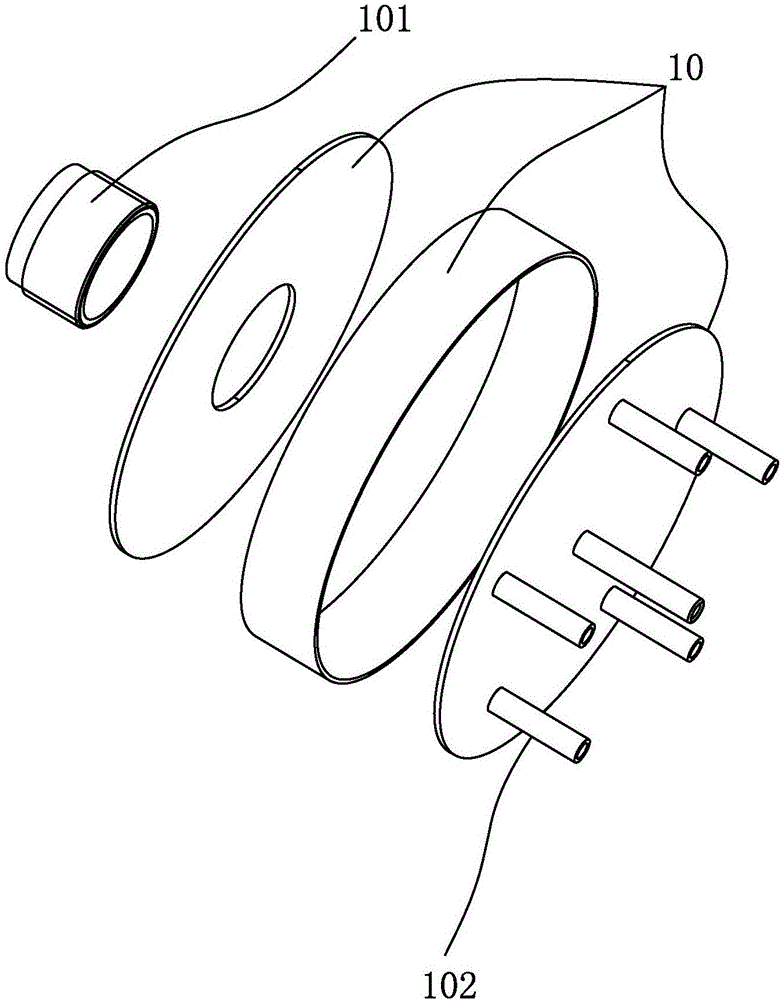

[0040] An automatic steam heating machine, including a frame 90, a nozzle 102, and a moving structure connected to the nozzle 102 and driving the nozzle 102 to move up and down. The moving structure is connected to the frame 90, and when working, it moves The structure drives the nozzle 102 to move to a designated position, mixes with the item to be heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com