Minimally-invasive perforation surgical tool and machining method thereof

A surgical tool and processing method technology, applied in the field of perforation surgical tools, can solve the problems of inability to accurately determine the position of perforation, increase the risk of carcinogenic lesions, and inconvenience for doctors to operate, so as to reduce blood vessel and nerve damage, reduce the number of operations, The effect of avoiding bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

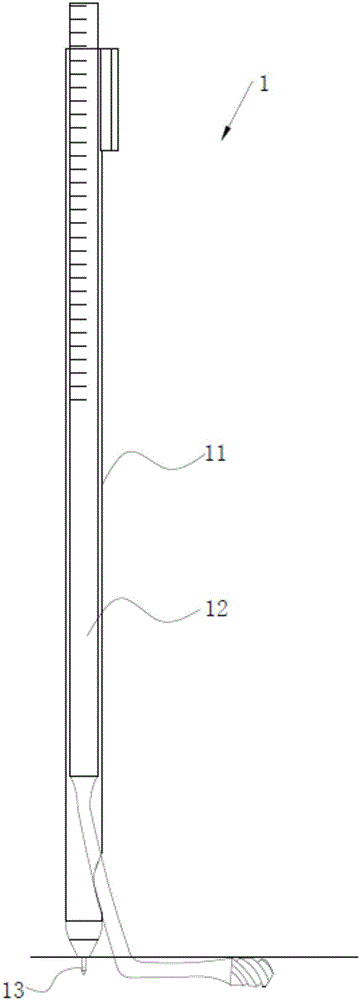

[0040] Such as figure 1 As shown, the minimally invasive perforation surgical tool 1 includes an open-circuit sleeve 11 and an open-circuit drill 12 disposed in the open-circuit sleeve 11 .

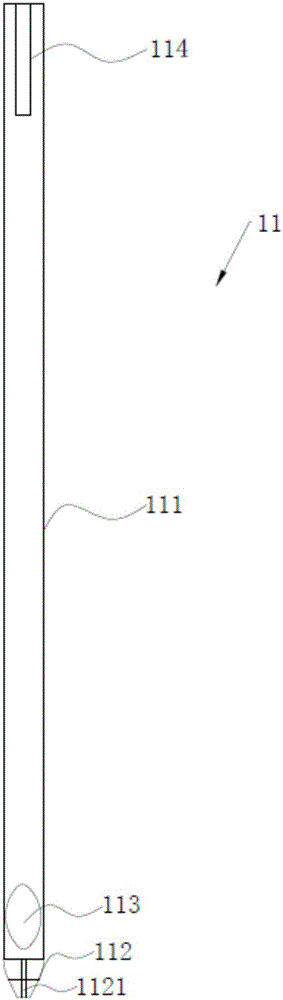

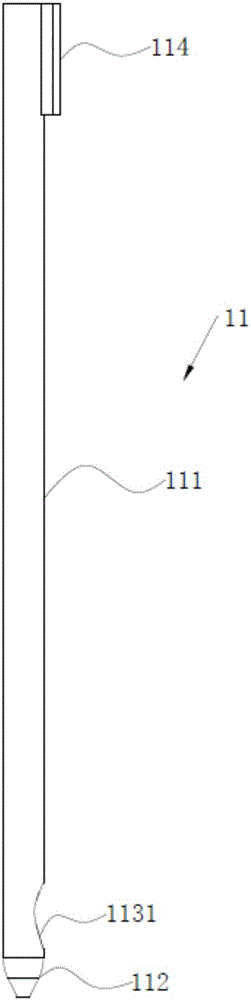

[0041] Please also refer to figure 2 and image 3 , the open-circuit sleeve 11 includes a sleeve body 111 and a core seat 112 that are connected to each other.

[0042] Please also refer to Figure 4 , the open circuit drill bit 12 includes a rod body 121 and a drill bit 122 , and also includes an elastic connecting rod 123 , and the drill bit 122 is connected to the rod body 121 through the elastic connecting rod 123 . The sleeve body 111 is provided with a drill bit outlet 113 , the rod body 121 is in the sleeve body 111 , and the drill bit 122 protrudes from the drill bit outlet 113 .

[0043]As mentioned above, the open-circuit sleeve 11 is used for positioning the needle, and the open-circuit drill bit 12 expands and contracts in the open-circuit sleeve 11 to perform perforation...

Embodiment 2

[0078] This embodiment provides a processing method of the minimally invasive perforating surgical tool 1 , which is used to manufacture the opening sleeve 11 and the opening drill 12 in the first embodiment. The open-circuit sleeve 11 is an integrally formed component, which is made by additive manufacturing. The open-circuit drill 12 is an integrally formed component, which is made by machining and grinding, and the open-circuit drill 12 is heat-treated.

[0079]The open-circuit sleeve 11 has a drill outlet 113 and a guide groove 1131. The open-circuit sleeve 11 is processed by an additive manufacturing method, which uses a computer to accurately control a high-energy laser beam or an electron beam to locally melt powdered metal materials and accumulate them layer by layer. According to the three-dimensional complex computer model, the solid parts with dense geometry are directly generated, so they are not limited by the processing structure. According to requirements, almos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com