Grain drying machine dust chamber

A dust removal room and dryer technology, applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problems of a large amount of dust, polluted air, time-consuming and laborious drying, etc., and achieve the effect of preventing excessive dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

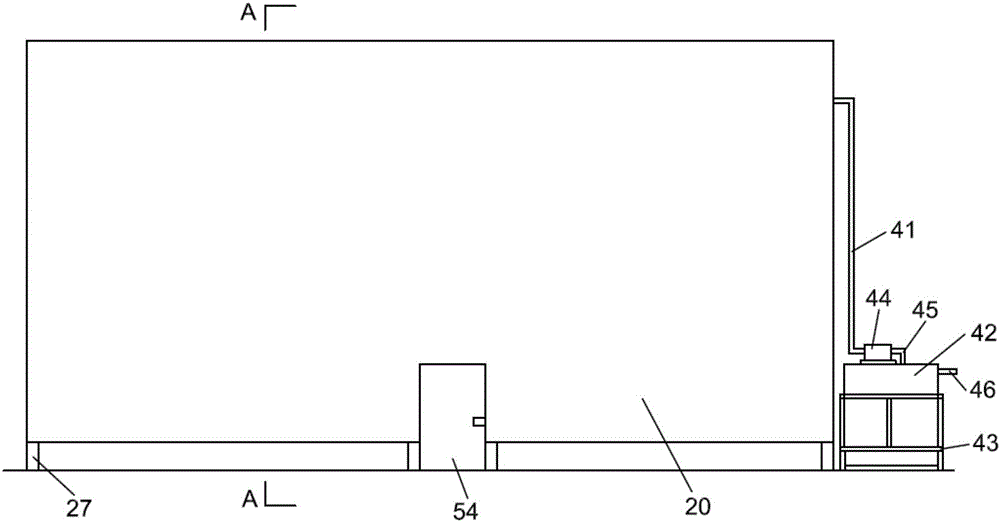

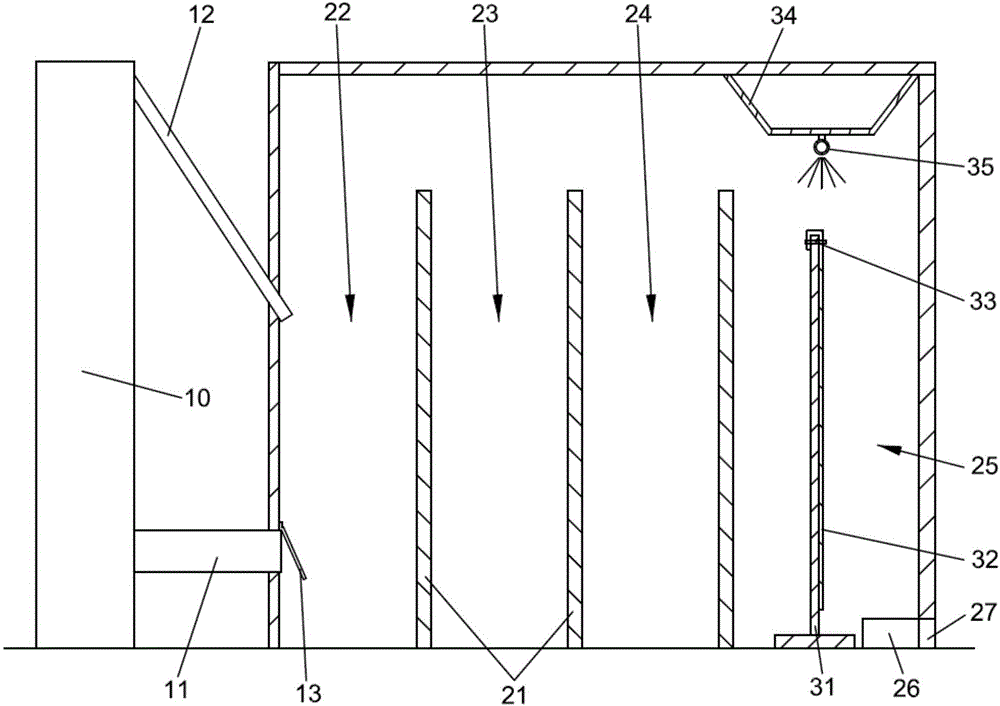

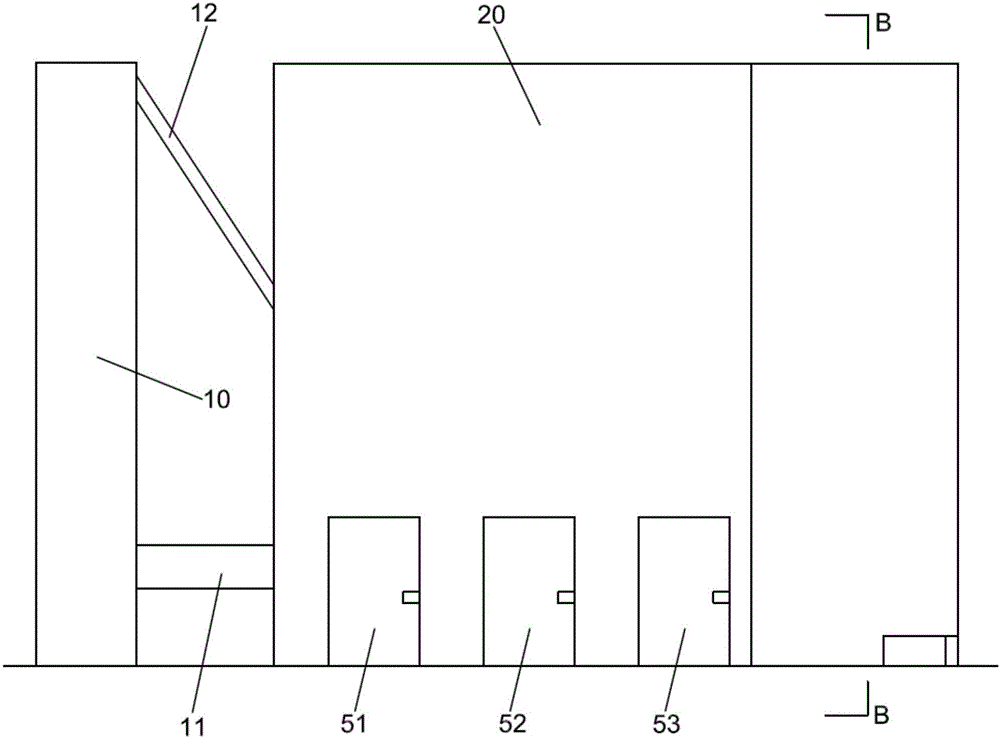

[0017] refer to Figure 1-Figure 4 , the present invention provides a dust removal room for a grain dryer, comprising a dust removal room body 20 and a grain dryer body 10, the dust removal room body 20 is provided with three partition walls 21 arranged in parallel, and the height of the three walls is lower than The height of the dedusting chamber, three partition walls 21 partition the interior of the dedusting chamber body 20 into the first partition chamber 22, the second partition chamber 23, the third partition chamber 24 and the fourth partition chamber 25; the bottom of the fourth partition chamber 25 is provided with The air outlet part 26 is provided with a support body 27 between the air outlet part 26 and the wall; the main air outlet pipe 11 is connected to the lower part of the grain dryer body 10, and the auxiliary air outlet pipe 12 is connected to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com