Pollution-free and clearly-printed colored tape and manufacturing process thereof

A manufacturing process and non-polluting technology, applied in printing, ink ribbon, textile and paper making, etc., can solve problems such as blurred text, difficult to distinguish handwriting, and affect the content of document transmission, etc., to achieve the effect of pollution-free printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

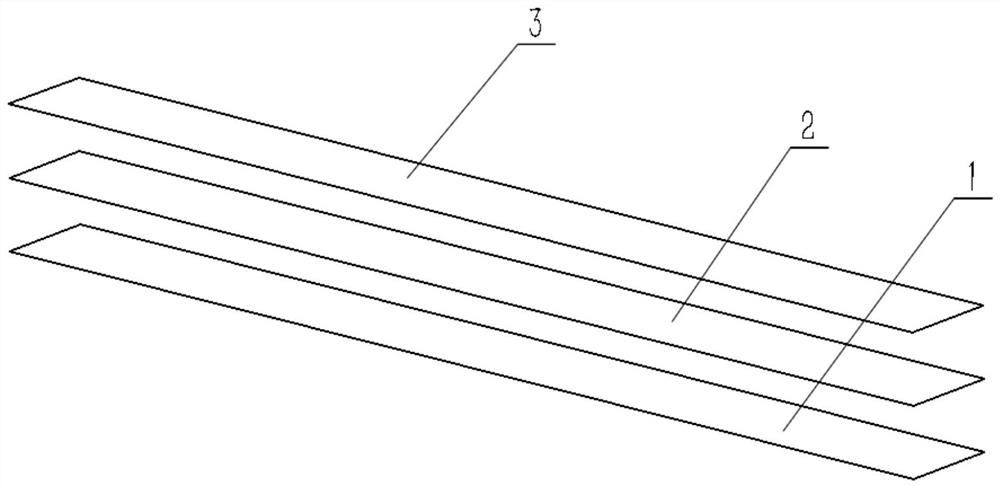

[0035] A pollution-free and clear-printed ribbon, which includes a ribbon fabric layer 1, an ink layer 2, and a wax layer 3 from the inside to the outside, and the ribbon fabric layer 1, ink layer 2, and wax layer 3 are closely attached to each other , The outermost wax layer will only print the ink on the paper when the printing needle hits and breaks, and no ink will leak out when the wax layer is hit and damaged, so it will not pollute the paper.

[0036] A pollution-free and clear printing ribbon manufacturing process, comprising the following steps:

[0037] a. Select nylon yarn to make ribbon fabric;

[0038] b. Carry out pre-shrinking scouring treatment on the ribbon fabric;

[0039] c. Soak the scoured ribbon gray cloth through the ink adsorption accelerator solution pool and squeeze it through the pressure roller to make the ribbon gray cloth fully absorb the accelerator solution;

[0040] d. Dry and shape the ribbon gray cloth;

[0041] e. Use a professional fusio...

Embodiment 2

[0053] A pollution-free and clear-printed ribbon, which includes a ribbon fabric layer 1, an ink layer 2, and a wax layer 3 from the inside to the outside, and the ribbon fabric layer 1, ink layer 2, and wax layer 3 are closely attached to each other , The outermost wax layer will only print the ink on the paper when the printing needle hits and breaks, and no ink will leak out when the wax layer is hit and damaged, so it will not pollute the paper.

[0054] A pollution-free and clear printing ribbon manufacturing process, comprising the following steps:

[0055] a. Select nylon yarn to make ribbon fabric;

[0056] b. Carry out pre-shrinking scouring treatment on the ribbon fabric;

[0057] c. Soak the scoured ribbon gray cloth through the ink adsorption accelerator solution pool and squeeze it through the pressure roller to make the ribbon gray cloth fully absorb the accelerator solution;

[0058] d. Dry and shape the ribbon gray cloth;

[0059] e, e. Use a professional melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com