Conductive microfiber synthetic leather and production method thereof

A production method and synthetic leather technology, applied in the manufacture of conductive/antistatic filaments, single-component polyamide artificial filaments, textiles and papermaking, etc., can solve the problem of carbon black and other fillers sedimentation, agglomeration, and limited product use environment , Unstable electrical conductivity and other issues, to achieve the effect of solving uneven electrical conductivity, stable product performance, and solving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

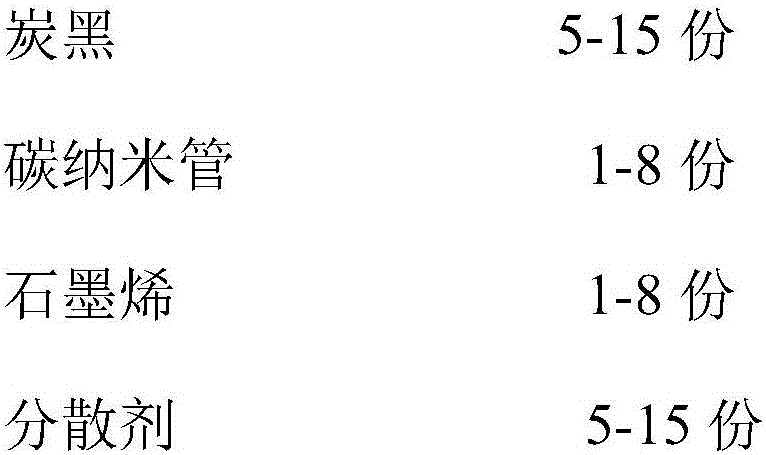

[0016] Proportion of conductive color masterbatch: (parts by weight)

[0017]

[0018]

[0019] Mix and granulate carbon black, carbon nanotubes, graphene, dispersant, heat stabilizer, antioxidant and nylon to obtain conductive color masterbatch;

[0020] After stirring and mixing the masterbatch and nylon evenly, the weight content of the masterbatch is 15%, and then the base fabric is made according to the above normal production steps, using the GBT 22845-2009 standard, and using a clamp-on multimeter (HIOKI 3280-10) Test the resistivity, and the resistivity of the base cloth is 1.0×104-7×104Ω-1.cm-1. The surface of the base cloth is relatively uniform without black spots.

Embodiment 2

[0022] Proportion of conductive color masterbatch: (parts by weight)

[0023]

[0024] Mix and granulate carbon black, carbon nanotubes, graphene, dispersant, heat stabilizer, antioxidant and nylon to obtain conductive color masterbatch;

[0025] After stirring and mixing the masterbatch and nylon evenly, the weight content of the masterbatch is 15%, and then the base fabric is made according to the above normal production steps, using the GBT 22845-2009 standard, and using a clamp-on multimeter (HIOKI 3280-10) The resistivity was tested, and it was found that the resistivity of the base cloth was 1.0×103-9×103Ω-1.cm-1, and the surface of the base cloth was relatively uniform without black spots.

Embodiment 3

[0027] Proportion of conductive color masterbatch: (parts by weight)

[0028]

[0029] Mix and granulate carbon black, carbon nanotubes, graphene, dispersant, heat stabilizer, antioxidant and nylon to obtain conductive color masterbatch;

[0030] After stirring and mixing the masterbatch and nylon evenly, the weight content of the masterbatch is 20%, and then the base fabric is made according to the above normal production steps, using the GBT 22845-2009 standard, and using a clamp multimeter (HIOKI 3280-10) The resistivity was tested, and the resistivity of the base cloth was 5.0×102-9×102Ω-1.cm-1, and the surface of the base cloth was relatively uniform without black spots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com