Bake type single-layer waterborne flashing paint for aluminum alloy hub and preparation method of waterborne flashing paint

An aluminum alloy wheel, flash paint technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as limitations, and achieve excellent recoating adhesion, good weather resistance, salt spray resistance, and acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

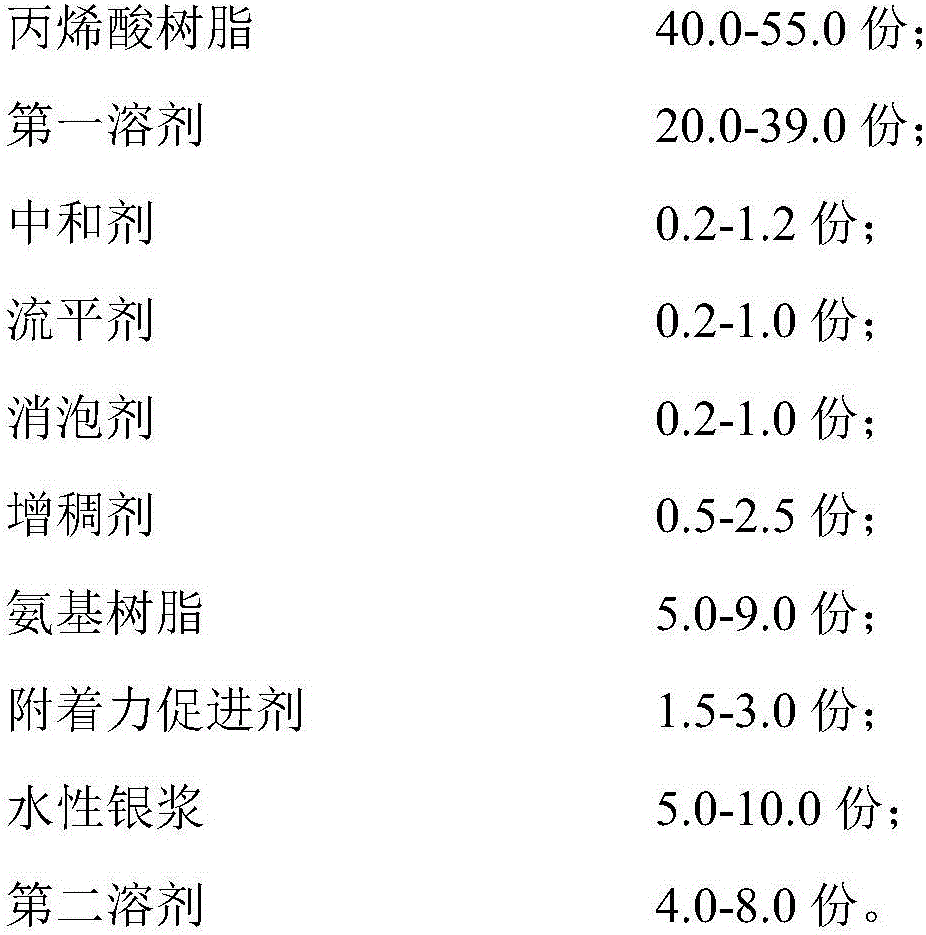

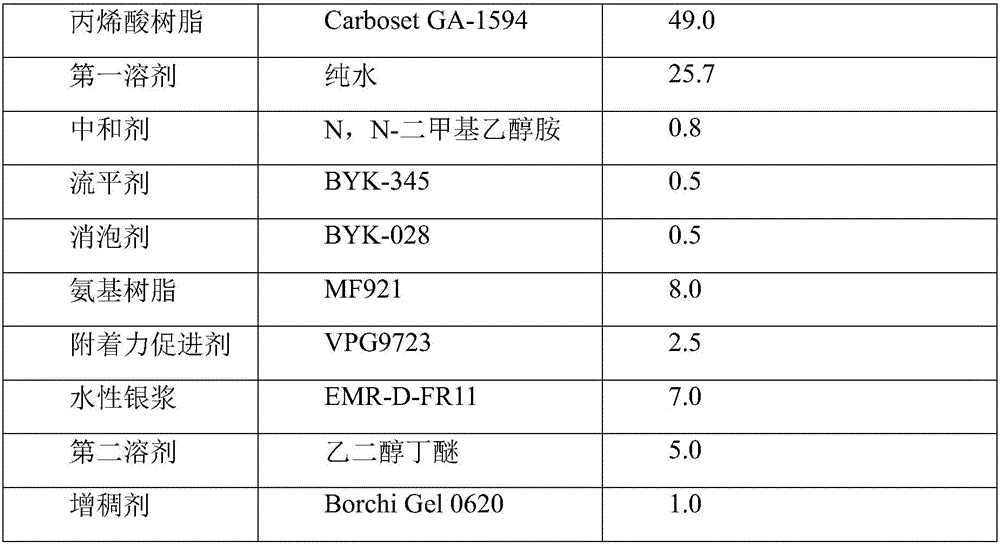

[0031] The aluminum alloy wheel hub of the present embodiment is made up of following composition with baking type single-layer water-based flash paint:

[0032] Table 1: Baking type single-layer water-based flash paint (embodiment 1) for aluminum alloy wheels

[0033]

[0034]

[0035] The preparation method of the baking-type single-layer water-based flash paint for the aluminum alloy wheel hub of the present embodiment may further comprise the steps:

[0036] S1: Add the water-based silver paste to the reaction kettle A, then add the second solvent and thickener, stir until it becomes a uniform slurry, then soak for 2 hours under this condition, and set aside;

[0037] S2: Add the acrylic resin to the reaction kettle B, and add a neutralizing agent to adjust the pH value to 7.5-8.5 under the condition of a rotating speed of 500 RPM;

[0038] S3: Add the first solvent into the reaction kettle B, and disperse for 10 minutes at a rotation speed of 500 RPM;

[0039] S4:...

Embodiment 2

[0045] The aluminum alloy wheel hub of the present embodiment is made up of following composition with baking type single-layer water-based flash paint:

[0046] Table 2: Baking type single-layer water-based flash paint (embodiment 2) for aluminum alloy wheels

[0047]

[0048]

[0049] The preparation method of the baking-type single-layer water-based flash paint for the aluminum alloy wheel hub of the present embodiment may further comprise the steps:

[0050] S1: Add the water-based silver paste to the reaction kettle A, then add the second solvent and thickener, stir until it becomes a uniform slurry, then soak for 1 hour under this condition, and set aside;

[0051] S2: Add the acrylic resin to the reaction kettle B, and add a neutralizing agent to adjust the pH value to 7.5-8.5 under the condition of a rotating speed of 1000 RPM;

[0052] S3: Add the first solvent into the reaction kettle B, and disperse for 5 minutes at a rotation speed of 1000 RPM;

[0053] S4: A...

Embodiment 3

[0059] The aluminum alloy wheel hub of the present embodiment is made up of following composition with baking type single-layer water-based flash paint:

[0060] Table 3: Baking type single-layer water-based flash paint (embodiment 3) for aluminum alloy wheels

[0061]

[0062]

[0063] The preparation method of the baking-type single-layer water-based flash paint for the aluminum alloy wheel hub of the present embodiment may further comprise the steps:

[0064] S1: Add the water-based silver paste to the reaction kettle A, then add the second solvent and thickener, stir until it becomes a uniform slurry, then soak for 2 hours under this condition, and set aside;

[0065] S2: Add the acrylic resin to the reaction kettle B, and add a neutralizing agent to adjust the pH value to 7.5-8.5 under the condition of a rotating speed of 800 RPM;

[0066] S3: Add the first solvent into the reaction kettle B, and disperse for 10 minutes at a rotation speed of 800 RPM;

[0067] S4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com