A kind of water-based coating solution of high weather resistance and heat and humidity resistance polyester film and preparation method thereof

A polyester film, moisture-resistant technology, applied in the direction of coating, can solve problems such as unfavorable long-term sustainable development, environmentally harmful substances, harm to human health, etc., and achieve the effect of reducing volume shrinkage, low volume shrinkage, and reducing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

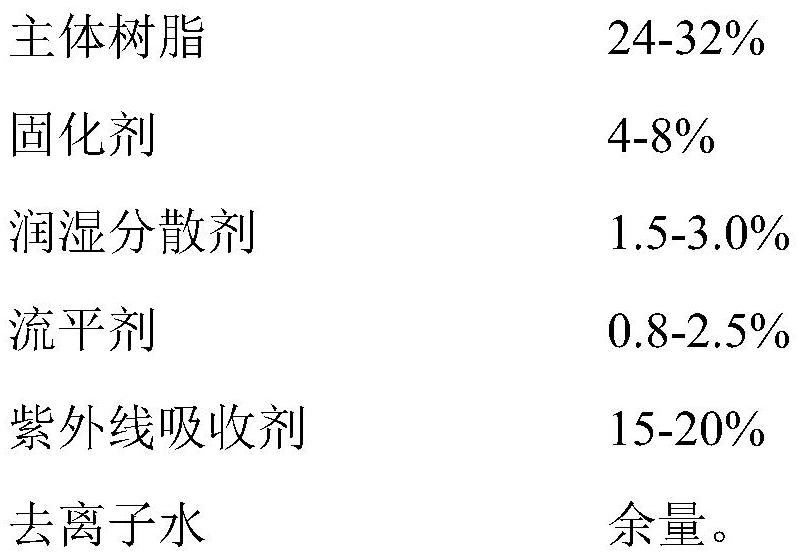

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: polyester modified acrylic resin 18%, thermoplastic acrylic resin 6%, blocked polyisocyanate 4%, DISPERBYK-180 1.8%, TEGO Glide 410 2.5%, rutile TiO 2 20%, the balance of deionized water.

[0027] Preparation:

[0028] (1) First add 1 / 2 of the formula content of polyester modified acrylic resin, rutile TiO 2 , DISPERBYK-180 were diluted with deionized water, and then mixed and stirred for 30 minutes;

[0029] (2) Use a ball mill to grind and disperse for 2 hours, and mix well;

[0030] (3) After grinding, slowly add the remaining polyester-modified acrylic resin, thermoplastic acrylic resin, and TEGO Glide 410 respectively, and continue stirring for 30 minutes;

[0031] (4) Slowly add blocked polyisocyanate, then add the remaining deionized water, and continue stirring for 1 hour.

[0032] The coating liquid is evenly coated on the surface of the polyester film through a slit coating head, and a coating with a thickness of 10 μm can be obtained after...

Embodiment 2

[0034] Raw materials: polyester modified acrylic resin 20%, thermoplastic acrylic resin 6.67%, blocked polyisocyanate 5.5%, DISPERBYK-180 2%, DISPERBYK-184 0.2%, TEGO Glide 482 1%, rutile TiO 2 15%, the balance of deionized water.

[0035] Preparation:

[0036] (1) First add 1 / 2 of the formula content of polyester modified acrylic resin, rutile TiO 2 , DISPERBYK-180, and DISPERBYK-184 were diluted with deionized water, and then mixed and stirred for 30 minutes;

[0037] (2) Use a ball mill to grind and disperse for 2 hours, and mix well;

[0038] (3) After grinding, slowly add the remaining polyester-modified acrylic resin, thermoplastic acrylic resin, and TEGO Glide 482, and continue to stir for 30 minutes;

[0039] (4) Slowly add blocked polyisocyanate, then add the remaining deionized water, and continue stirring for 1 hour.

[0040] The coating liquid is uniformly coated on the surface of the polyester film through a slit coating head, and a coating with a thickness of...

Embodiment 3

[0042] Raw materials: polyester modified acrylic resin 21%, thermoplastic acrylic resin 7%, blocked polyisocyanate 6%, DISPERBYK-184 2.1%, TEGO Glide 410 1.0%, TEGO Glide 482 0.4%, rutile TiO 2 18%, the balance of deionized water.

[0043] Preparation:

[0044] (1) First add 1 / 2 of the formula content of polyester modified acrylic resin, rutile TiO 2 , DISPERBYK-184 were diluted with deionized water, and then mixed and stirred for 30 minutes;

[0045] (2) Use a ball mill to grind and disperse for 2 hours, and mix well;

[0046] (3) After grinding, slowly add the remaining polyester-modified acrylic resin, thermoplastic acrylic resin, TEGO Glide 410, and TEGO Glide 482 respectively, and continue stirring for 30 minutes;

[0047] (4) Slowly add blocked polyisocyanate, then add the remaining deionized water, and continue stirring for 1 hour.

[0048] The coating liquid is uniformly coated on the surface of the polyester film through a slit coating head, and a coating with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com