Comprehensive aging treatment method for railway traffic equipment large metal component

A technology for metal components and aging treatment, applied in the field of rail transit equipment testing, to achieve the effect of strong operability, elimination of residual stress, and high elimination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

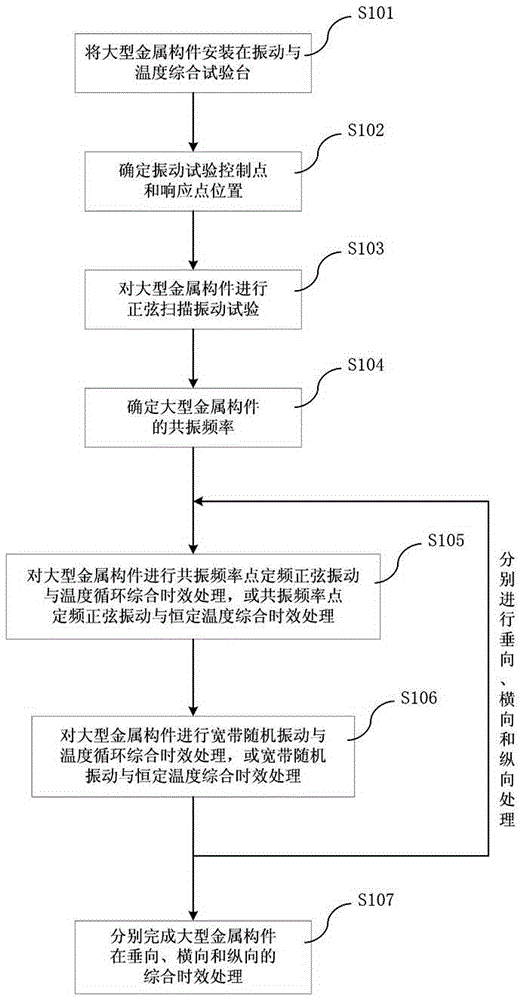

[0083] as attached figure 1 As shown, a specific embodiment of a comprehensive aging treatment method for large metal components of rail transit equipment, comprising the following steps:

[0084] S101: Install the large metal component 1 on the vibration and temperature comprehensive test bench;

[0085] S102: Determine the location of the vibration test control point and response point;

[0086] S103: Conduct a sinusoidal scanning vibration test on the large metal component 1;

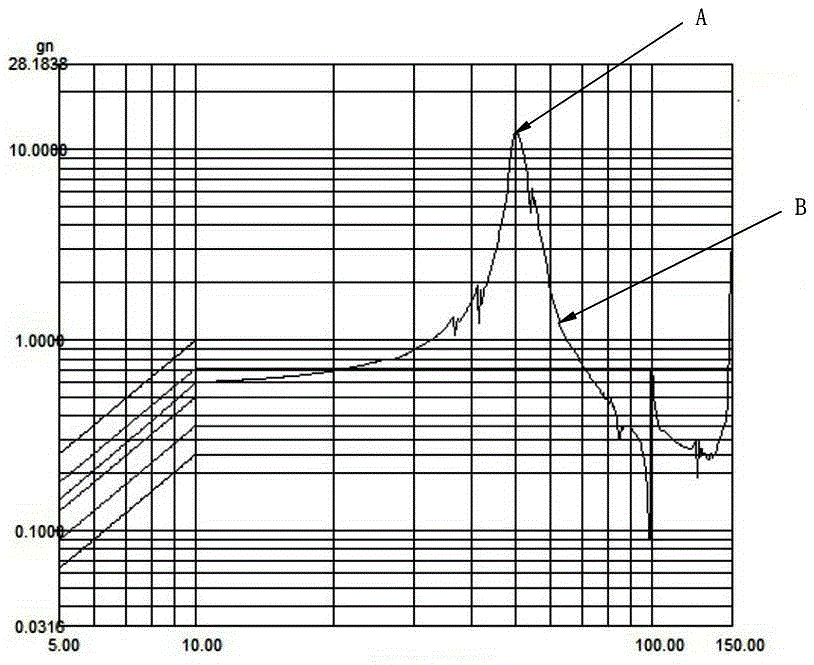

[0087] S104: determining the resonance frequency of the large metal component 1;

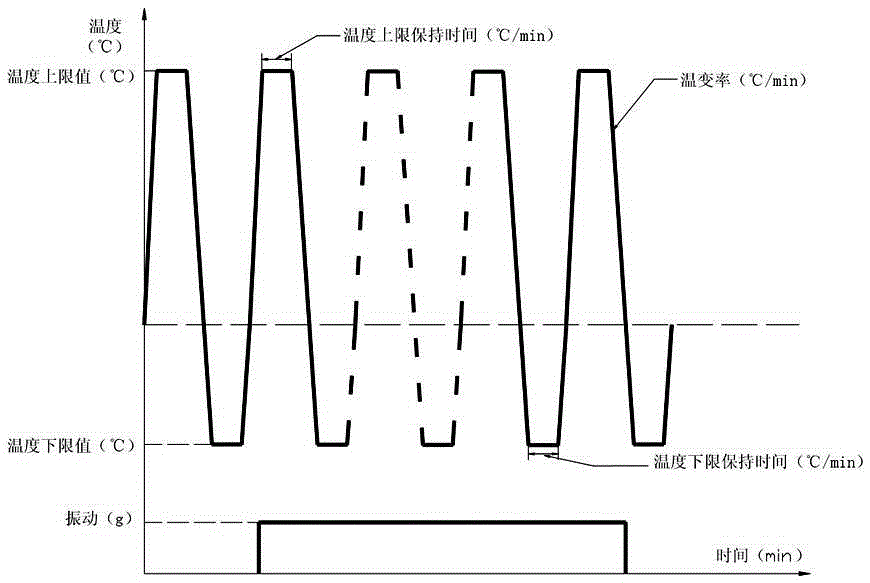

[0088] S105: Perform comprehensive aging treatment on the large metal component 1 with fixed-frequency sinusoidal vibration at the resonance frequency point and temperature cycle;

[0089] S106: Perform comprehensive aging treatment of broadband random vibration and temperature cycle on the large metal component 1;

[0090] S107: Repeat the above steps S102 to S106 to complete the comprehensive aging treatment of t...

Embodiment 2

[0129] Another specific embodiment of a comprehensive aging treatment method for large metal components of rail transit equipment, comprising the following steps:

[0130] S101: Install the large metal component 1 on the vibration and temperature comprehensive test bench;

[0131] S102: Determine the location of the vibration test control point and response point;

[0132] S103: Conduct a sinusoidal scanning vibration test on the large metal component 1;

[0133] S104: determining the resonance frequency of the large metal component 1;

[0134] S105: Perform comprehensive aging treatment of broadband random vibration and temperature cycle on the large metal component 1;

[0135] S106: Perform comprehensive aging treatment on the large metal component 1 with fixed-frequency sinusoidal vibration at the resonance frequency point and temperature cycle;

[0136] S107: Repeat the above steps S102 to S106 to complete the comprehensive aging treatment of the large metal member 1 in...

Embodiment 3

[0139] Embodiment 3 On the basis of the above-mentioned Embodiment 1 and Embodiment 2, the comprehensive aging treatment of fixed-frequency sinusoidal vibration and temperature cycle at the resonance frequency point, and the temperature cycle aging treatment in the comprehensive aging treatment of broadband random vibration and temperature cycle are replaced by constant Temperature aging treatment. The scheme of constant temperature aging treatment is adopted, for example: during the aging treatment of fixed-frequency sinusoidal vibration at the resonance frequency point or the aging treatment of broadband random vibration, a constant temperature (thermal stress) of 150-200°C is applied to the large metal component 1 at the same time and the set temperature is maintained. The time (usually 60~120min) can also achieve the effect of comprehensive aging of heat and vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com