Antibacterial nano fiber and preparation method thereof

A nanofiber and fiber technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of low cost and good spinnability, and achieve the effects of low cost, strong application value and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First add 100 grams of cocoons to 1 liter of 0.5w / v% Na 2 CO 3 In the aqueous solution, boil for 30min, repeat the treatment three times, fully wash with distilled water, put it in a drying oven at 45°C after washing, and dry to obtain degummed silk fibers; 2 :C 2 h 5 OH:H 2 The molar ratio of O=1:2:8 is used to prepare a ternary solvent, and the silk fiber is hydrolyzed at a constant temperature in a water bath at 70° C. for 1 hour at a bath ratio of 1:10 to obtain a completely dissolved brownish-yellow silk fiber hydrolysis solution; Put the hydrolyzed solution into a dialysis bag, dialyze with distilled water for 72 hours, put the dialyzed silk fiber hydrolyzed solution into -80°C for 12 hours, and then freeze-dry it at -58°C until dry to obtain white, loose porous, spongy Silk fibroin: Compared with the existing commercially available silk fibroin, the silk fibroin prepared by the above steps of the present invention has the advantages of uniform molecular weigh...

Embodiment 2

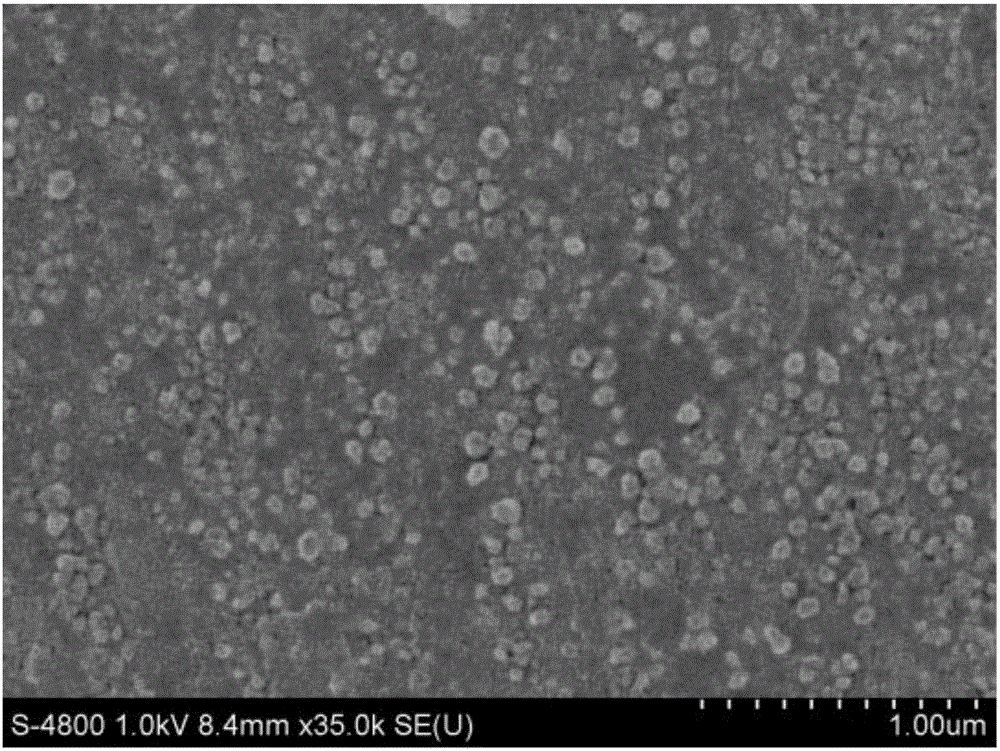

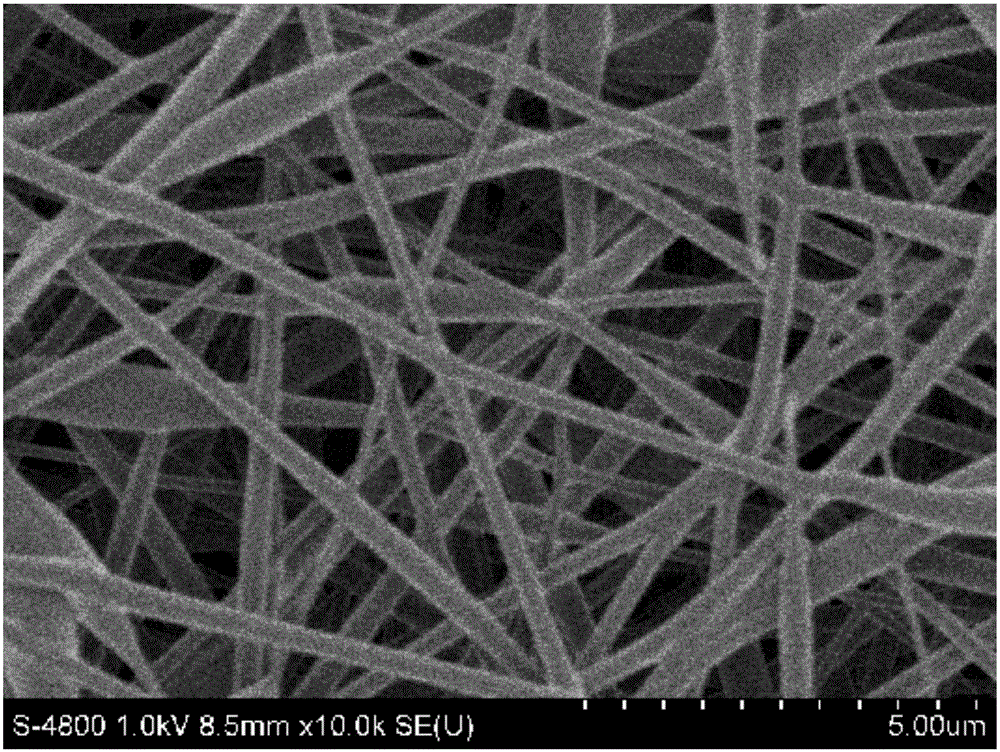

[0034]Disperse 0.01 g of nano-cuprous oxide powder in 10 ml of deionized water, ultrasonicate for 2 hours, add 2.0 g of silk fibroin prepared in Example 1 and stir until completely dissolved to obtain a silk fibroin solution; dissolve 0.2 g of polyethylene oxide in 10 In milliliters of deionized water, stir until fully dissolved to obtain a polyethylene oxide solution with a mass fraction of 2.0%. 10 mL of silk fibroin solution containing nano-cuprous oxide is mixed with 10 mL of polyethylene oxide solution so that the mass ratio of the two solutions is 1:1, then electrospinning, spinning conditions: voltage, 12 kV; receiving distance, 150 mm; spinning rate, 0.8 ml / hour, to obtain an antibacterial nanofiber membrane with an average fiber diameter of 289±70 nm.

Embodiment 3

[0036] Disperse 0.005 g of nano-cuprous oxide powder in 10 ml of deionized water, ultrasonicate for 2 hours, add 2.0 g of silk fibroin prepared in Example 1 and stir until completely dissolved to obtain a silk fibroin solution with a volume and mass dispersion of 20.0%; 1 gram of polyethylene oxide was dissolved in 10 milliliters of deionized water, stirred until completely dissolved to obtain a polyethylene oxide solution with a mass fraction of 2.0%, and 10 mL of silk fibroin solution containing nanometer cuprous oxide was mixed with 10 mL of polyethylene oxide solution to make The mass ratio of the two solutions is 1:1, and then electrospinning is carried out. The spinning conditions are: voltage, 12 kV; receiving distance, 150 mm; spinning rate, 0.8 ml / hour, and the average fiber diameter is 337 ± 62 Nano antibacterial nanofiber membrane.

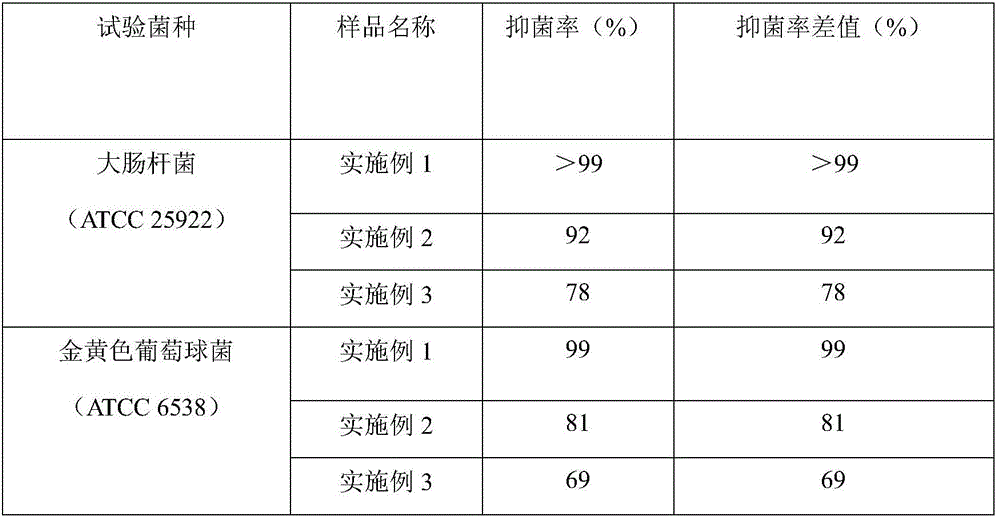

[0037] Before the antibacterial experiment, the antibacterial nanofiber membrane was treated with 75% ethanol vapor, which not only ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap