Online non-woven fabric perforating system

A technology of non-woven fabrics and punching devices, which is applied to the cutting of non-woven fabrics, textiles and papermaking, and textile materials, can solve the problems of high processing cost, multi-manpower, and multi-process, so as to reduce labor costs and production. cost, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

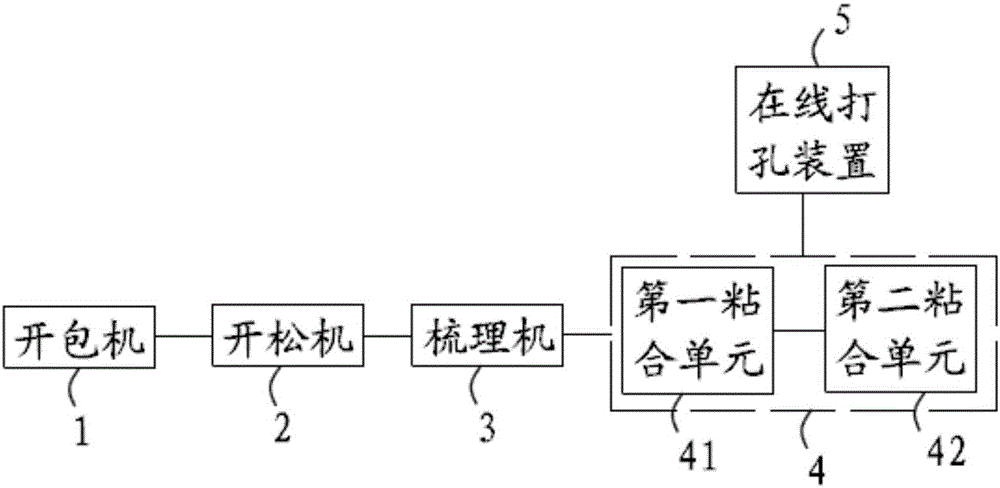

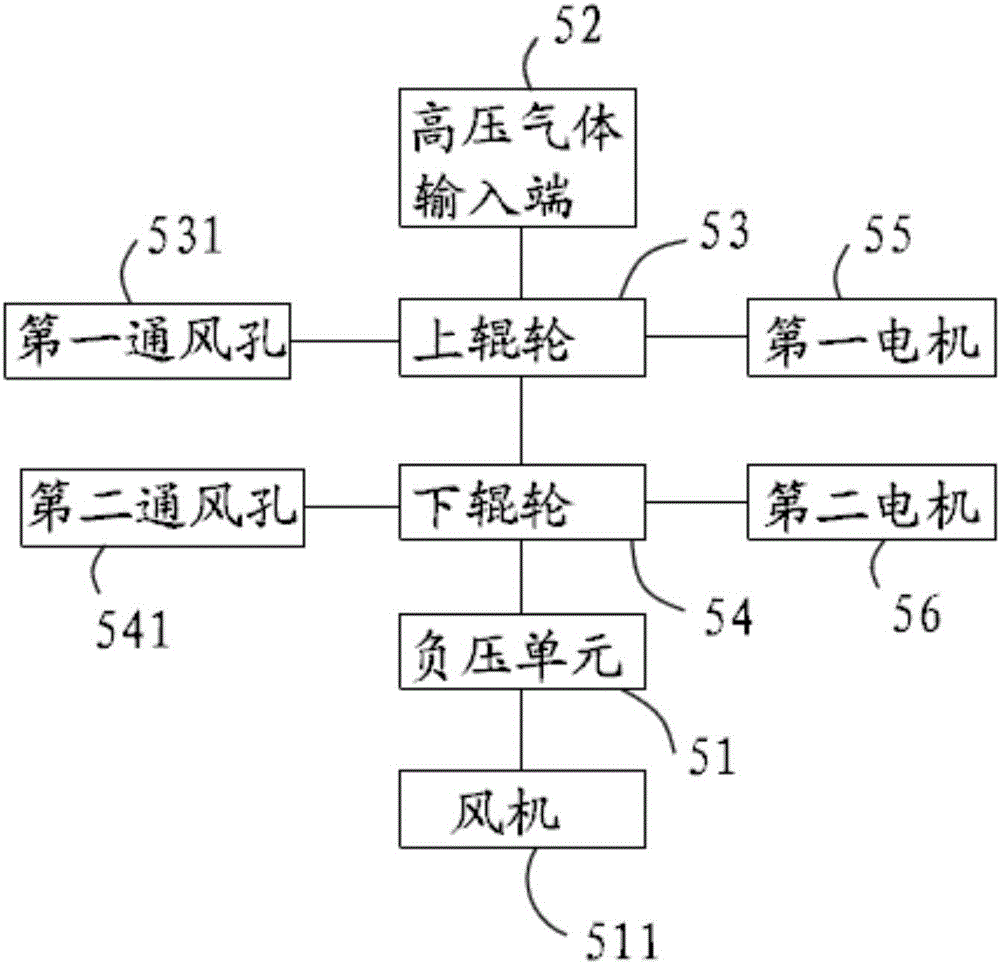

[0016] Such as figure 1 and figure 2 As shown, the non-woven fabric online punching system includes a bale opener 1, an opener 2, a carding machine 3, and a hot air bonding mechanism 4. The opener 2 corresponds to the bale opener 1, and the carding machine 3 corresponds to the opener 2. Correspondingly, the fibers pass through the bale opener 1, the opener 2, the carding machine 3 and the hot air bonding mechanism 4 in turn, and the hot air bonding mechanism 4 is provided with an online punching device 5, and the online punching device 5 includes a negative pressure unit 51 and a high pressure The gas input end 52 and the negative pressure unit 51 are arranged below the high pressure gas input end 52 .

[0017] When this non-woven online punching system is in use, after the unpacking machine 1 unpacks the fibers of different components, the unpacking machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com