Side wing foundation scour-resistant reinforcing structure for enhancing stability of road shoulder wall

A technology for strengthening structures and foundations. It is used in infrastructure engineering, underwater structures, water conservancy projects and other directions. It can solve problems such as high engineering costs, increased section size and foundation depth, and poor integrity, and achieves investment savings and savings. Engineering cost and maintenance cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

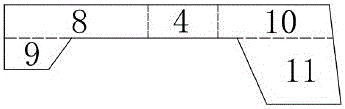

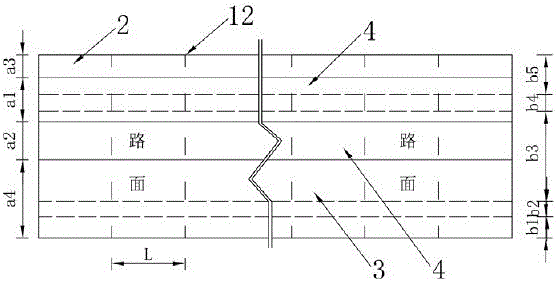

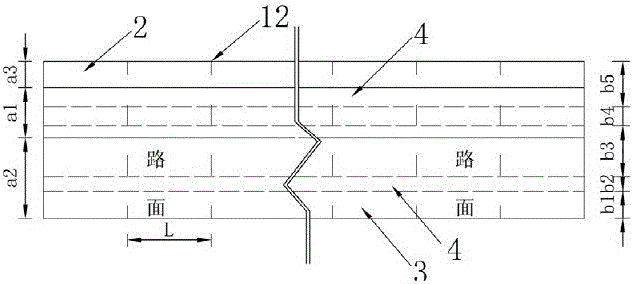

[0036] Embodiment one: if figure 1 , 2 , 3, and 4 show that the slope of the river is 140‰, and the subgrade height is 6m. On the river bed, build a 100m-long road shoulder wall 1, adopt the shoulder wall 1 with the L-shaped beam tooth wall foundation 2 at the wall toe and the L-shaped beam tooth wall foundation 3 at the wall heel, and adopt a convex line wall The interior surface 5 optimizes the structure of the inner wing of the shoulder wall 1 . First construct the L-shaped beam tooth wall foundation 2 at the wall toe and the L-shaped beam tooth wall foundation 3 at the wall heel, and then construct the upper wall 4 on the road. The inner and outer wings of the shoulder wall are respectively provided with a wall toe L-shaped beam tooth wall foundation 2 and a wall heel L-shaped beam tooth wall foundation 3 for reinforcement, and are connected with the upper wall body 4 as a whole.

[0037] A flank foundation anti-scour reinforcement structure for enhancing the stability ...

Embodiment 2

[0053] Embodiment two: if figure 1 , 5 As shown in , 6, the slope of the river is 52‰, and the subgrade height is 2.5m. A flank foundation anti-scour reinforcement structure for enhancing the stability of the shoulder wall includes a base embedded in the river bed, and an upper wall 4 established on the base, the base includes the upper wall 4, The wall toe L-shaped beam tooth wall foundation 2 on the outer two sides and the wall heel L-shaped beam tooth wall foundation 3, the wall outer side 6 of the upper wall 4 is an inclined plane, and the wall inner side 5 is a broken line surface .

[0054] The same as Embodiment 1 will not be repeated, the difference is: the L-shaped beam tooth wall foundation 3 at the wall heel is arranged on the inner side of the lower end surface of the upper wall 4, the wall heel pressure plate 8 and the wall heel tooth wall 9 The outer side is on the same vertical plane and is continuously connected with the inner side 5 of the wall, and the inn...

Embodiment 3

[0059] Embodiment three: as figure 1 , 2 , 3, 4, 7, and 8, a flank foundation anti-scour reinforcement structure for enhancing the stability of the shoulder wall includes a base embedded in the river bed, and an upper wall 4 set up on the base. The base includes a wall toe L-shaped beam tooth wall foundation 2 and a wall heel L-shaped beam tooth wall foundation 3 which are arranged on the inner and outer sides of the upper wall body 4. The wall outer surface 6 of the upper wall body 4 is One inclined plane, the inner side surface 5 of the wall is a broken line plane.

[0060] The same as the first embodiment will not be repeated, the difference is: when the shoulder wall 1 is eroded by the water flow at the head and tail ends of the longitudinal extension, the two single shoulder walls 1 at the head and tail ends are poured in a fully enclosed way To prevent water from entering the gap between the L-shaped beam tooth wall foundation 2 at the toe of the wall and the L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com