Thin type double-layer solid wood heated floor

A geothermal floor and solid wood technology, applied to layered products, wood layered products, floors, etc., can solve problems such as unreasonable structure and unsatisfactory heat transfer effect, and achieve structure saving, overall thickness reduction, and difficulty in absorbing water deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

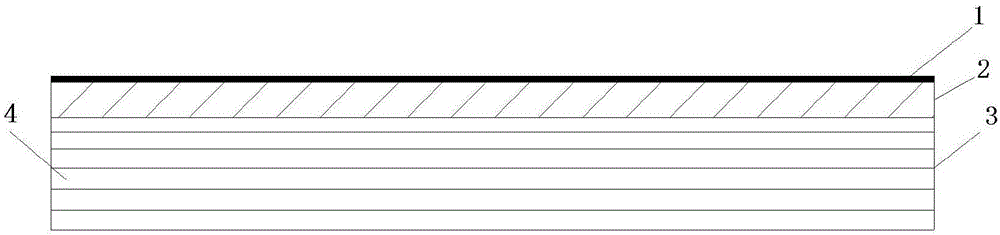

[0014] A kind of thin double-layer solid wood geothermal floor of the present embodiment, as figure 1 As shown, it includes a solid wood substrate 3, grooves and tenons are provided around the solid wood substrate 3, a solid wood panel 2 is provided above the solid wood substrate 3, a layer of topcoat 1 is provided on the solid wood panel 2, and a moisture-proof paint layer is provided below; The substrate is composed of 5-7 layers of veneers 4 .

[0015] The top paint 1 of this embodiment is vegetable oil.

[0016] The solid wood panel 2 in this embodiment is made of teak or oak.

[0017] The thickness of the solid wood substrate 3 in this embodiment is between 11mm-17mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com