Design finalization external protective frame system used for assembly type building construction

A building construction and stereotyped technology, applied in the direction of construction, building structure, scaffolding supported by house structure, etc., can solve the problems of many safety hazards, many materials, repair work, etc., and achieve reliable structural design, high safety factor, and use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

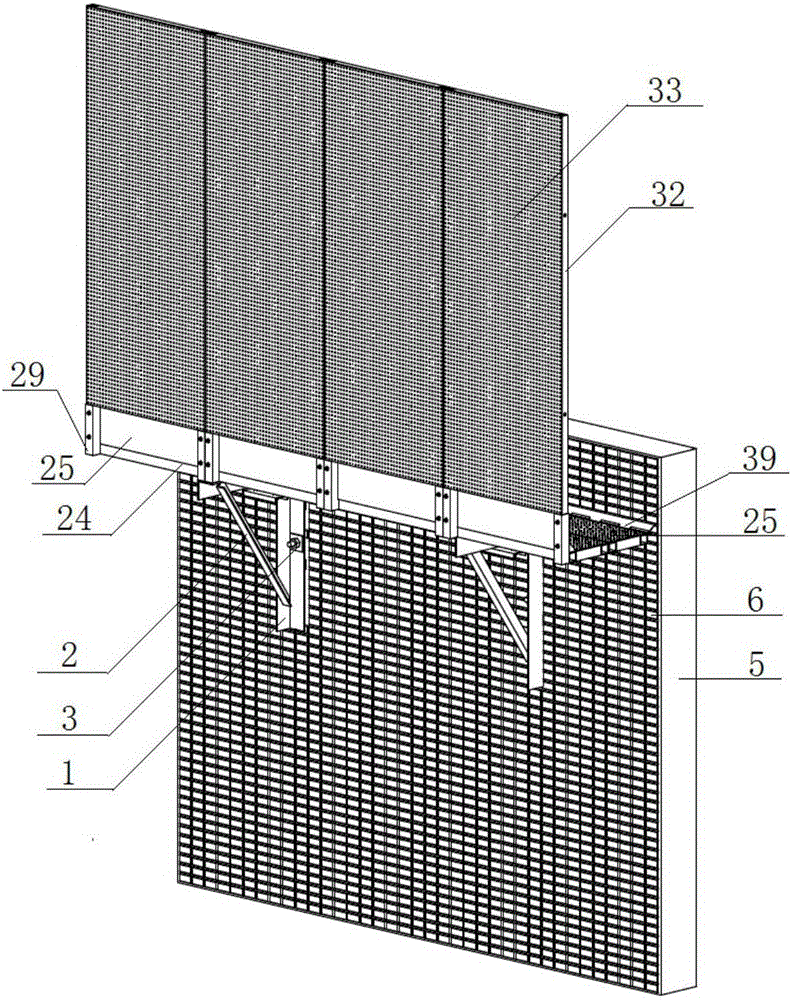

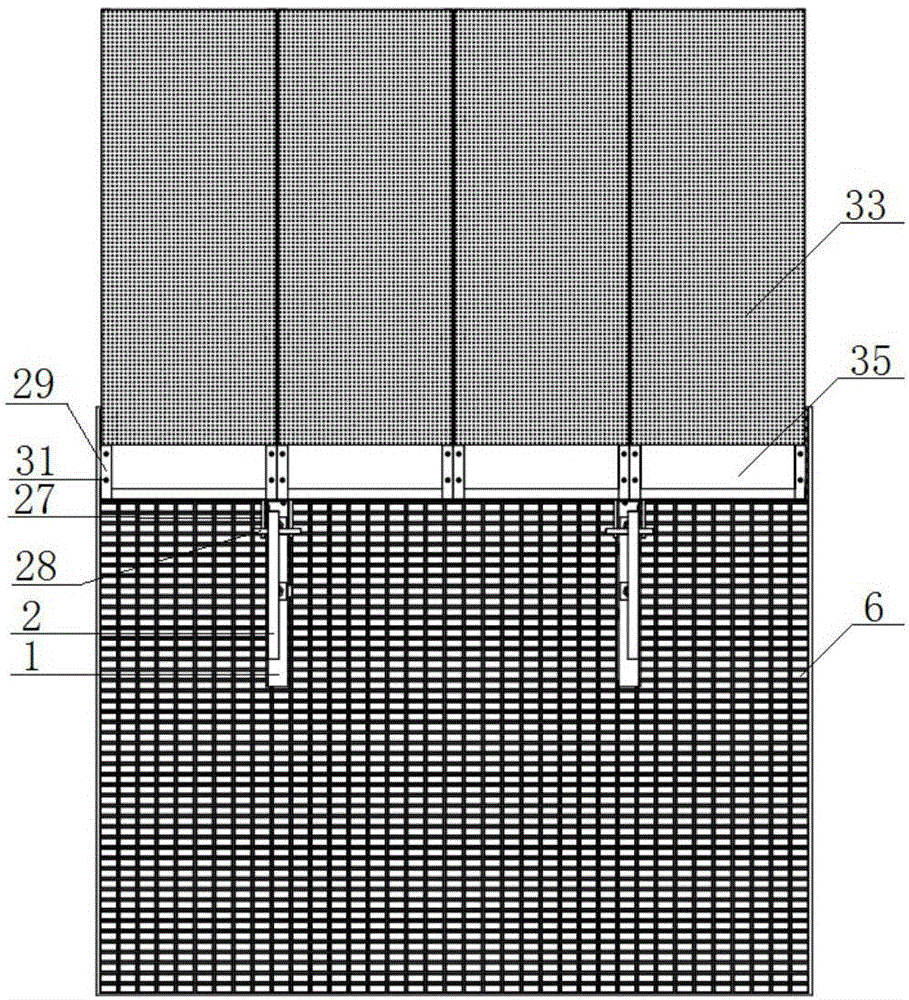

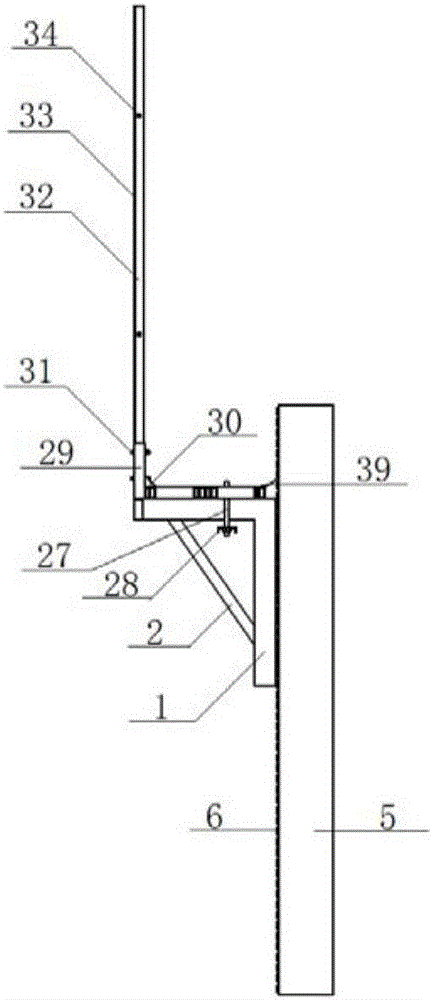

[0036] like Figure 1 to Figure 7 As shown, the outer protective frame system of the present invention is composed of three types of frames: a standard outer protective frame, a bay window outer protective frame, and a balcony outer protective frame. Each type of outer protective frame is composed of three parts: a support device, a horizontal protective device, a vertical protective device, the three types of outer protective frames share the same horizontal and vertical protective devices, and the horizontal and vertical protective devices are customized in the factory using modules, which are combined according to prefabricated components of different sizes and assembled into a frame that meets the size of the enclosure, and designed out the corresponding support device.

[0037] like Figure 1 to Figure 4 , Figure 13 , Figure 16 , Figure 17 As shown, the supporting device of the standard outer protective frame is formed by the combination of the right-angle brace 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com