Assembly type segment lining structure of large-section horseshoe tunnel

A horseshoe-shaped, large-section technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of circular tunnels without structural advantages and low space utilization, so as to improve space utilization and structural stability, reduce The effect of volume and overall structure design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

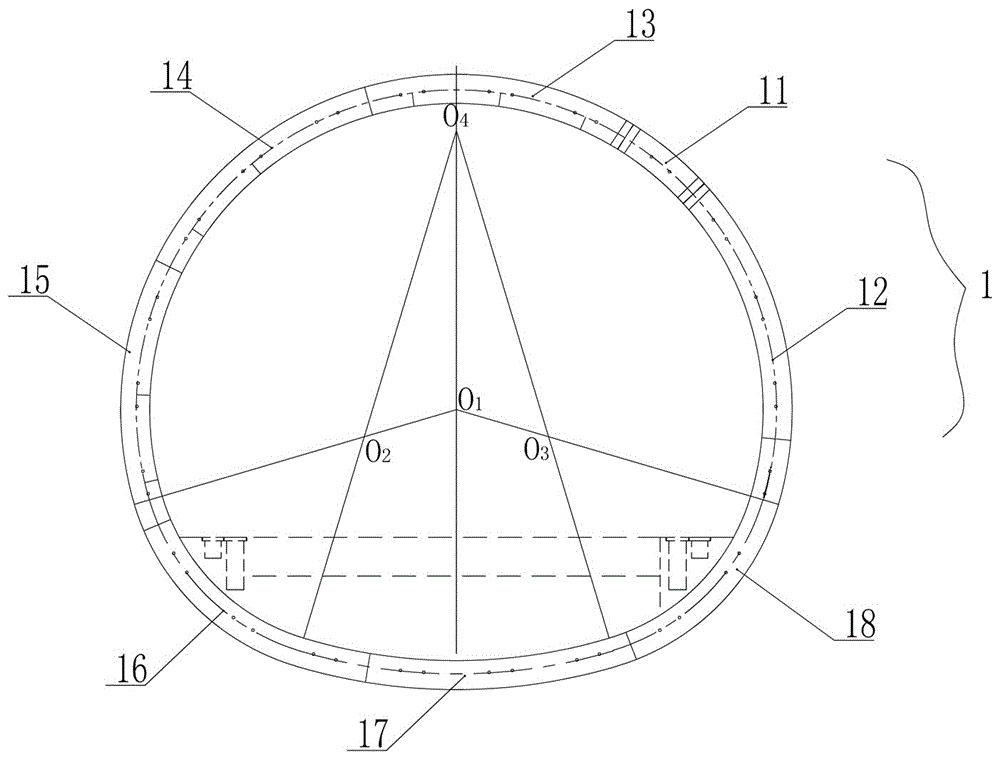

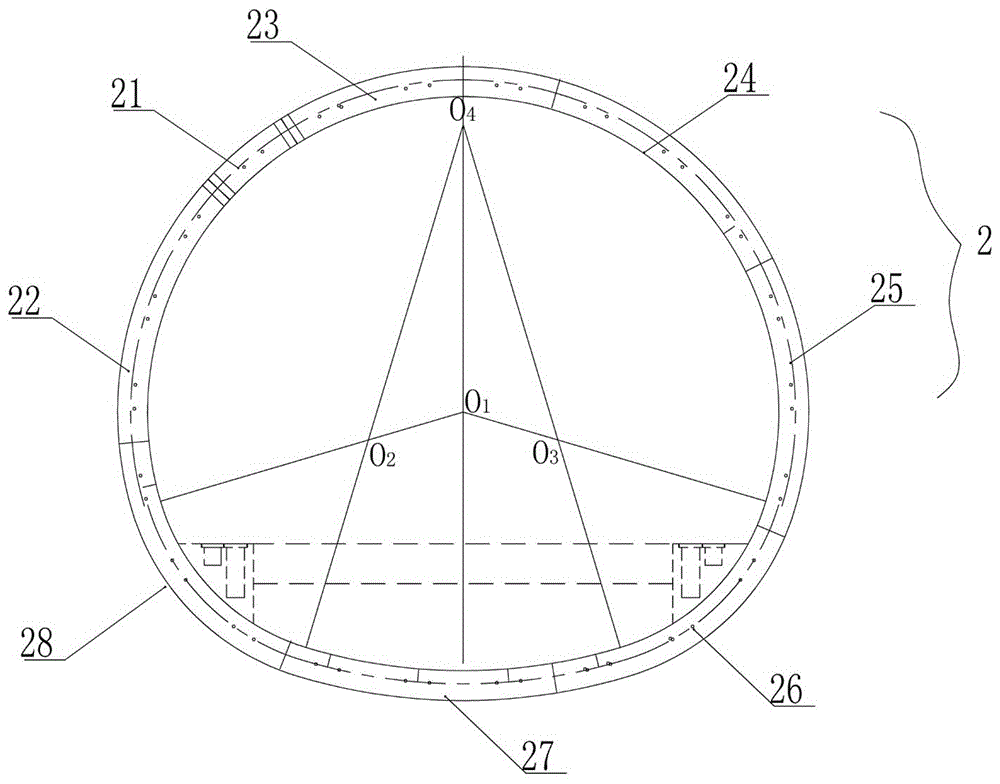

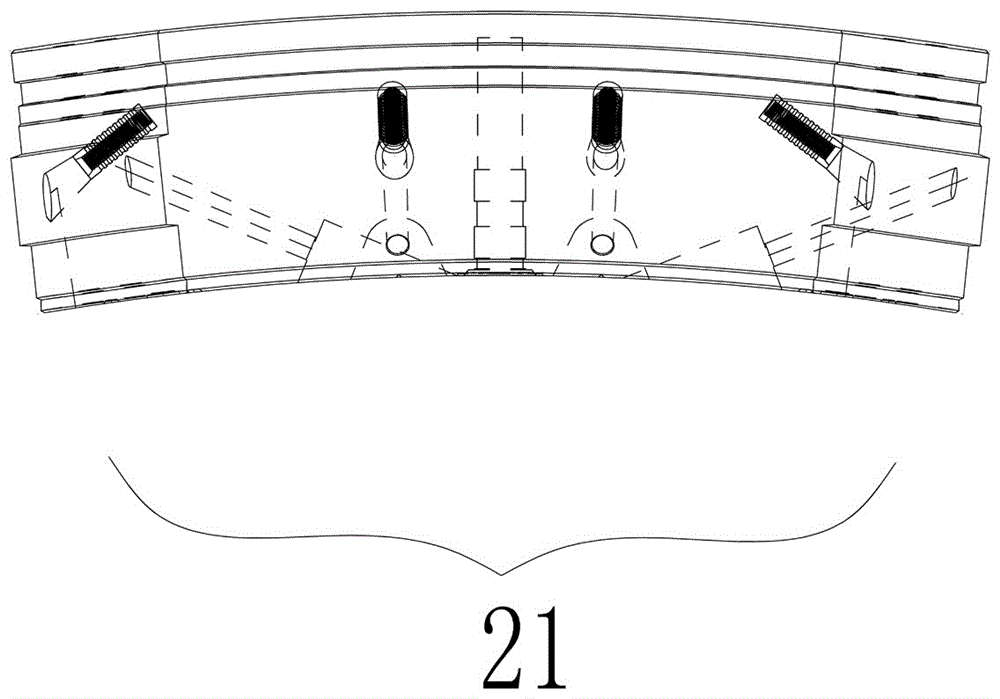

[0040] see Figure 1-Figure 18 , an assembled segment lining structure for a large-section horseshoe-shaped tunnel according to the present invention, wherein the tunnel section of the segment lining is a horseshoe-shaped structure with smooth transitions of multiple circular arcs, and the main body shape of the segment lining consists of a top circular arc and two middle circular arcs. arc and a section of bottom arc are smoothly transitioned to form a horseshoe-shaped structure with four centers and three diameters (arcs with three different radius sizes and four centers), such as figure 1 with figure 2 Shown, O 1 , O 2 , O 3 , O 4 is the center of four circular arcs, the tunnel section of the segment lining is left-right symmetrical, and the layout structure of the segments in the odd-numbered segment ring units and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com