Movement conversion device based on vehicle vibration

A technology of motion conversion and motion conversion mechanism, applied in the direction of the mechanism, engine, elastic engine, etc. that generate mechanical power, it can solve the problems of hydraulic pipeline leakage, low applicability, complex structure, etc., so as to prolong the service life and avoid energy The effect of loss, support to restore balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

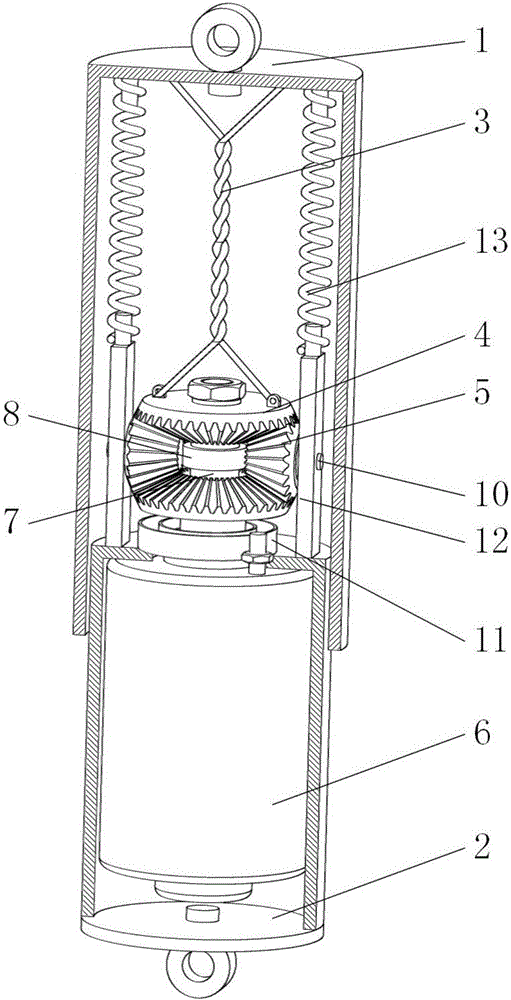

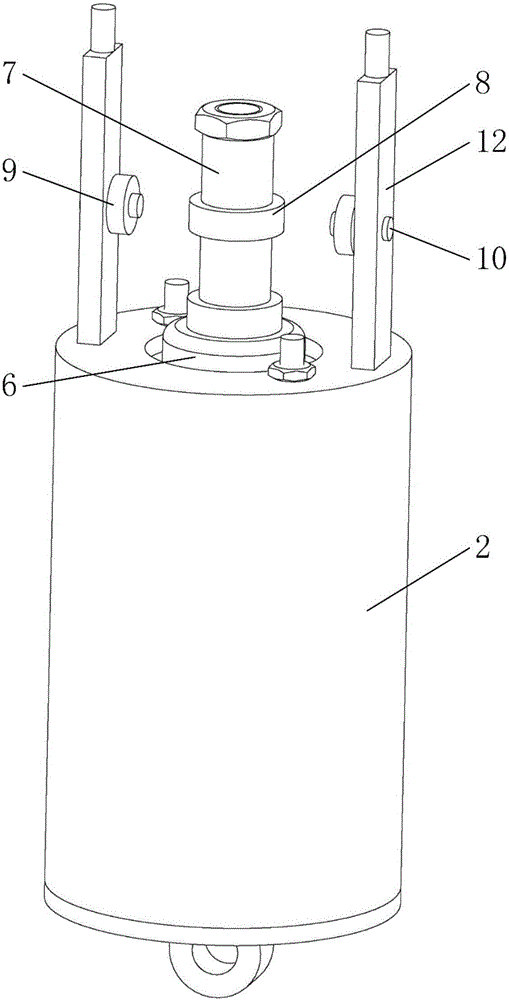

[0021] A motion conversion device based on vehicle vibration, including an upper sleeve 1, a lower sleeve 2, a motion conversion mechanism and a motor 6, the upper sleeve 1 and the lower sleeve 2 are clearance fit; the motor 6 is located on the lower sleeve 2 Inside, the motor shaft faces upward and is exposed at the opening of the lower sleeve 2; a thrust bearing 8 is provided in the middle of the motor shaft, and a one-way bearing 7 is provided above and below the thrust bearing 8; the one-way bearing 7 on the top and The lower one-way bearings 7 are respectively matched with a group of large bevel gears opposite to the tooth surface; one end of the steel wire rope 3 is located on the top inner side of the upper sleeve 1, and the other end is fixed to the axial back of the upper large bevel gear 1-4; the lower sleeve The two sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com