Automotive board light with reflection electric light source

A technology of diffused light and electric light source, applied in the field of automobile diffused light, can solve the problems of easy accident, high power consumption and high failure rate, and achieve the effect of ensuring normal work, increasing life and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

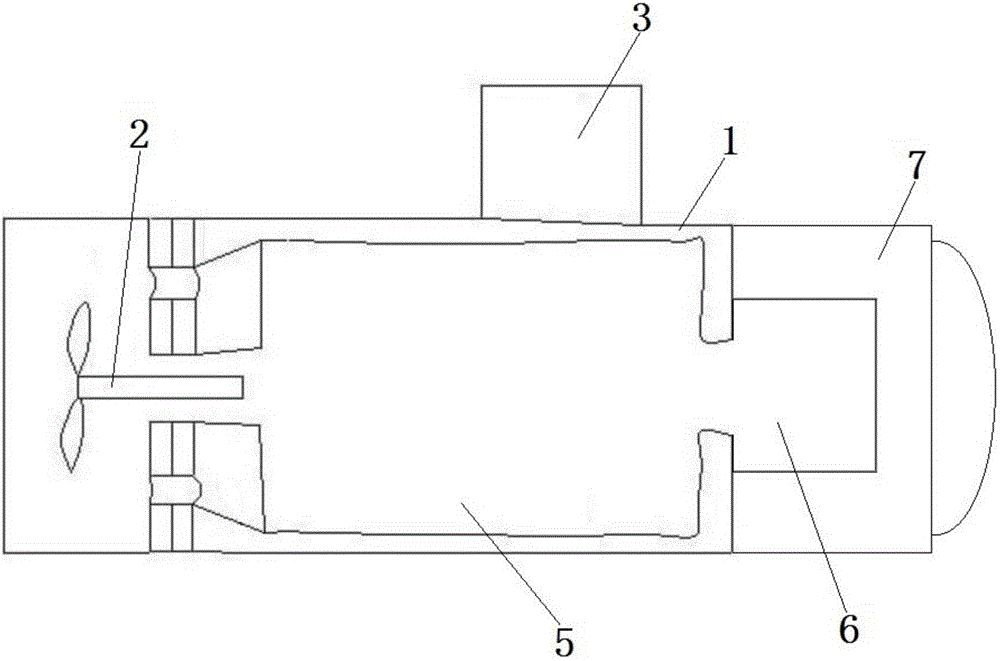

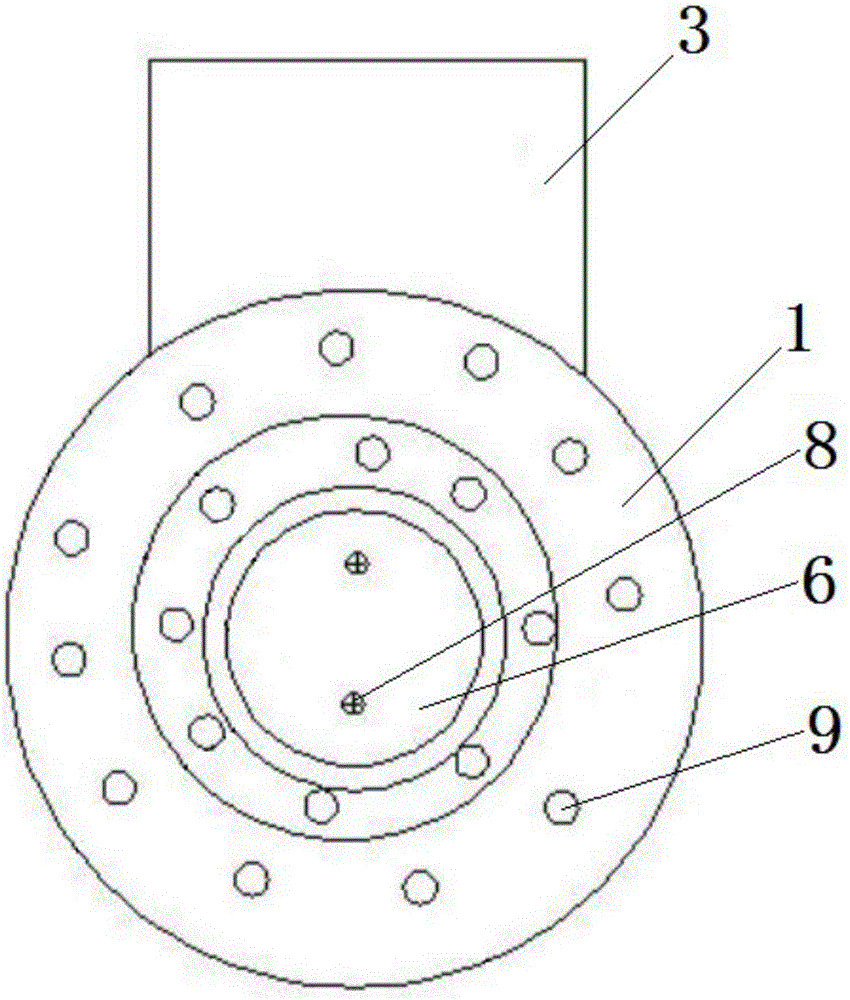

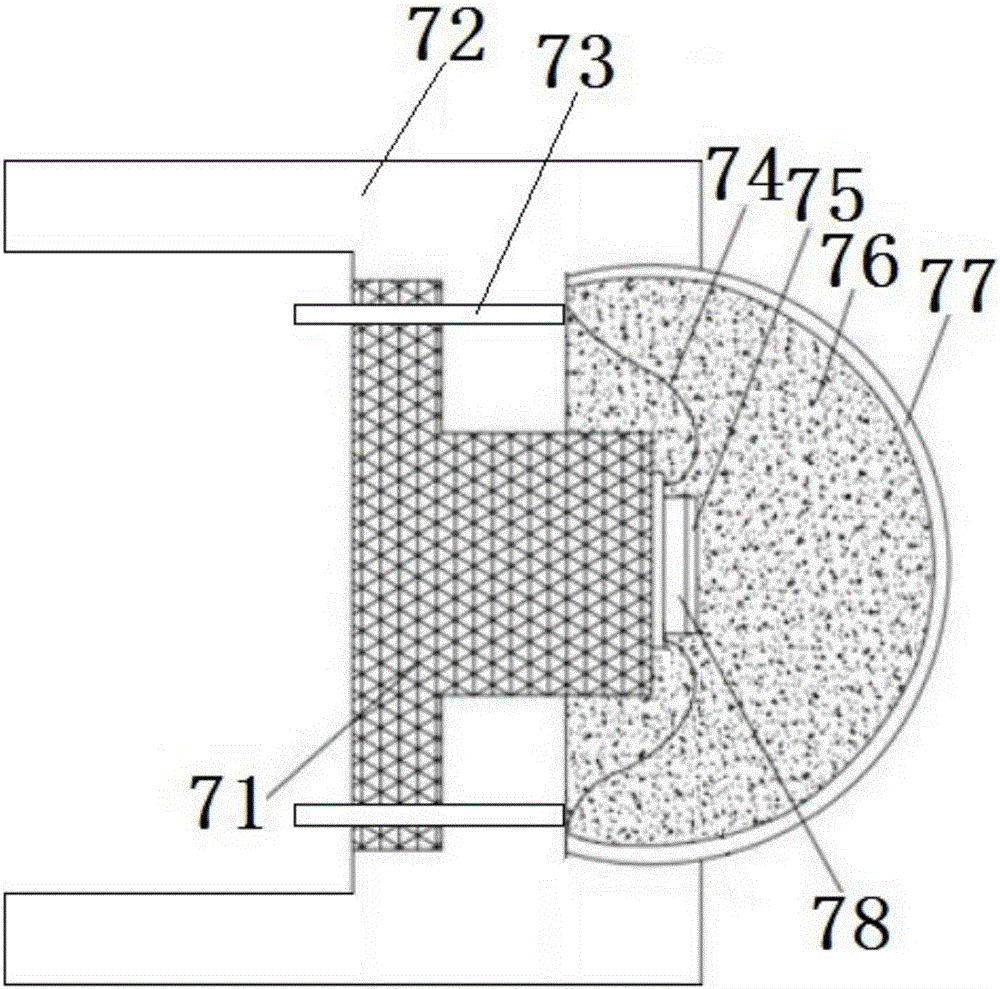

[0025] refer to Figure 1-4 , a kind of automobile diffuse light through reflected electric light source, comprises lamp holder 1 and lamp bead 7, and described lamp holder 1 is made of ceramic material, and above lamp holder 1 is provided with wiring holder 3, and inside lamp holder 1 is provided with cavity 5. The front end of the lamp holder 1 is provided with a lamp bead bayonet 6, and the lamp bead bayonet 6 is provided with a thread, and the lamp bead bayonet 6 is screwed to the lamp bead 7 through the thread, and the lamp bead bayonet 6 is provided with a terminal 8. The lamp holder 1 of ceramic material is the carrier of each part on the lamp holder 1, and at the same time, it can withstand high temperature and maintain the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com