Environment-friendly furnace core structure and manufacturing method thereof

A production method and environment-friendly technology, applied in the direction of combustion method, combustion type, household stove/stove, etc., can solve the problems of poor versatility, poor heating effect, insufficient coal combustion, etc., and achieve strong practicability, convenient production, good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

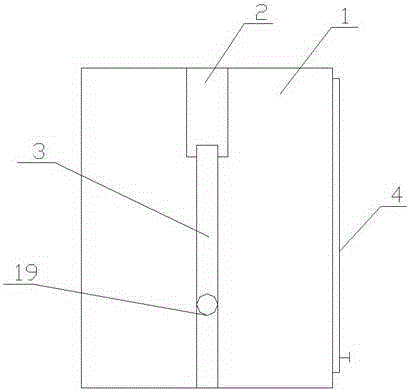

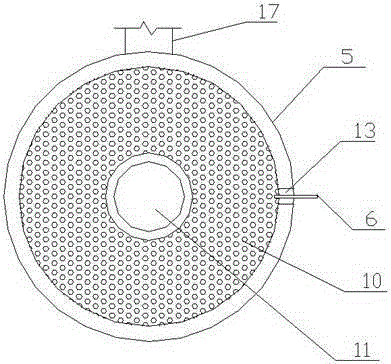

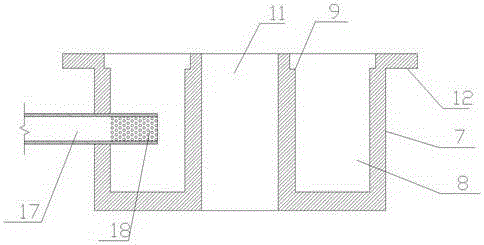

[0019] Embodiments of the present invention: a manufacturing method of an environment-friendly furnace core structure, including a furnace core body, the furnace core body is a cavity structure that penetrates up and down, a notch is provided on one side of the upper edge of the furnace core body, and a gas delivery pipe It is installed on the outside of the furnace core body and the gas outlet end of the gas delivery pipe corresponds to the position of the notch. On the other side of the furnace core body, a line connected to the power supply is provided. The furnace head of the furnace core is placed on the furnace core body through the guide of the notch. Wherein the gas inlet of the burner is communicated with the gas delivery pipe, and the igniter of the burner is communicated with the circuit.

[0020] The burner head of the furnace core includes a burner base, and an annular groove is set on the burner base so that the horizontal section of the burner base is a "back" st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com