An anti-dust, anti-wear and anti-corrosion flue gas heat exchanger

A flue gas heat exchanger, anti-wear technology, applied in the direction of heat exchanger, indirect heat exchanger, heat exchanger type, etc., can solve the problem of poor convective heat transfer capacity of dust accumulation, reduce tail dust accumulation, strengthen Convective heat transfer performance, enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the embodiments described in the accompanying drawings.

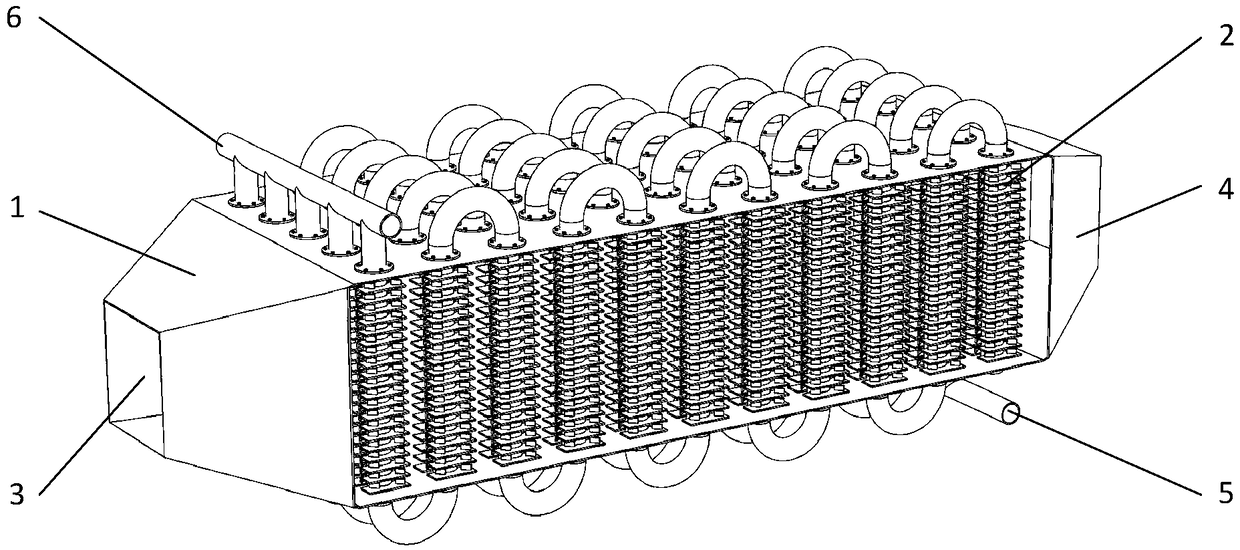

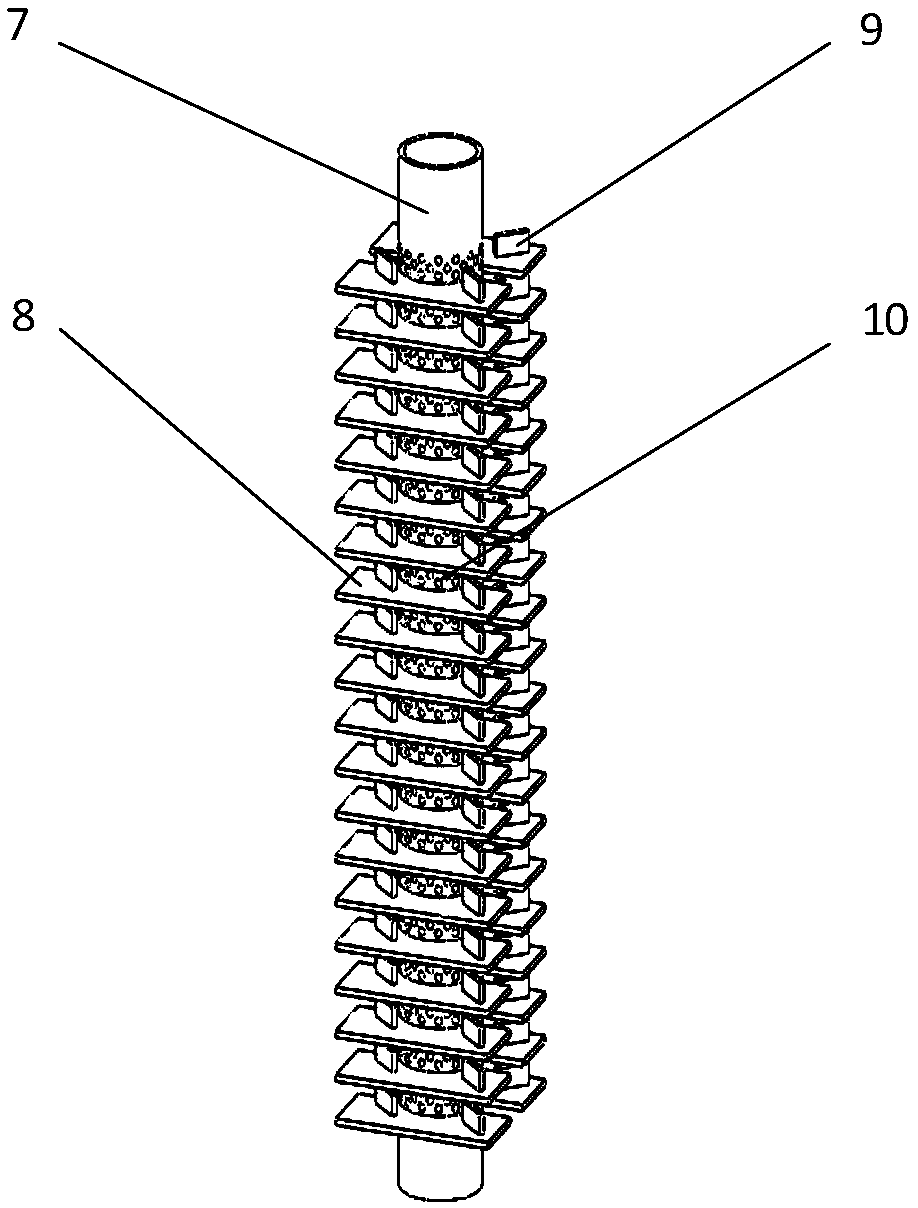

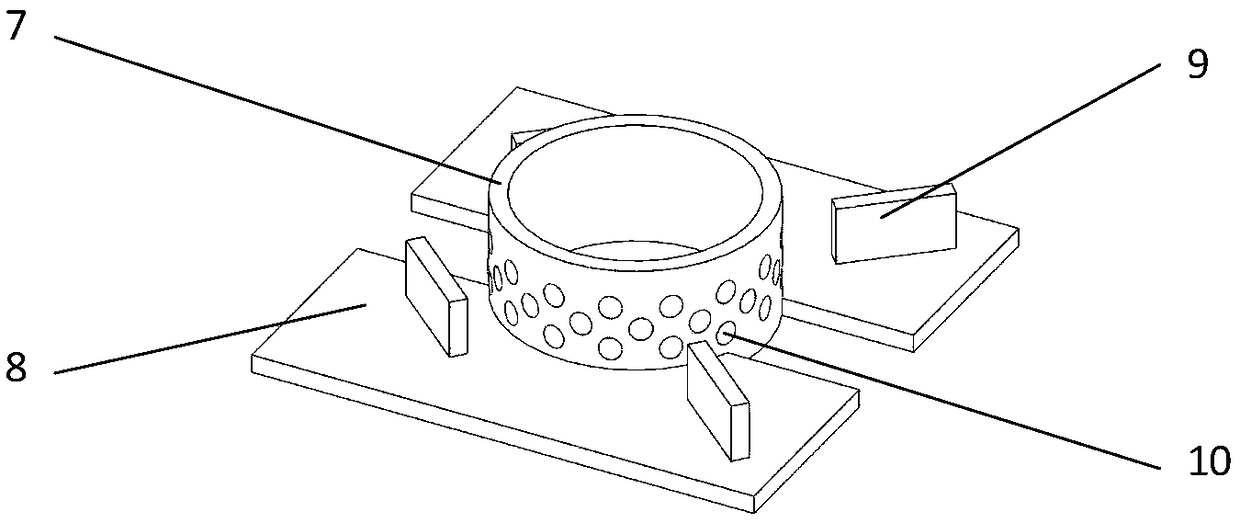

[0028] see figure 1 , 2, 3, the present invention includes a heat exchanger shell 1 and a finned tube bundle 2, wherein the finned tube bundle 2 is arranged in the heat exchanger shell 1 in a row arrangement, and the heat exchanger shell 1 The two opposite sides are respectively provided with an extra-tube medium inlet 3 and an extra-tube medium outlet 4. The finned tube bundle 2 includes a number of connected base tubes 7 and a number of fin groups 8 installed on the base tubes 7. An inlet 5 for medium in the pipe and an outlet 6 for medium in the pipe are arranged on the top. The set of fins 8 is a set of fins connected to the outer wall of the base tube at predetermined intervals along the axial direction of the base tube, wherein each set of fins includes two quadrilateral fins located on both sides of at least one base tube, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com