Method for collecting latent heat of solidification of cold water

A collection method, cold water technology, applied in the field of energy, can solve problems such as inability to extract solidification latent heat, inability to timely and effectively peel off, high processing precision requirements, etc., and achieve the effects of low investment, improved efficiency, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

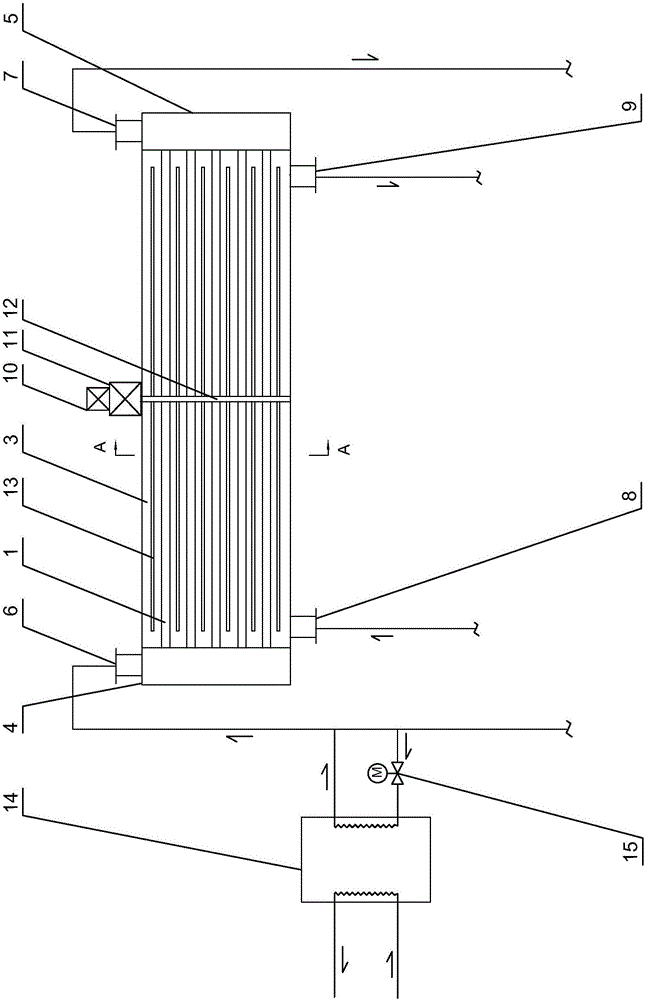

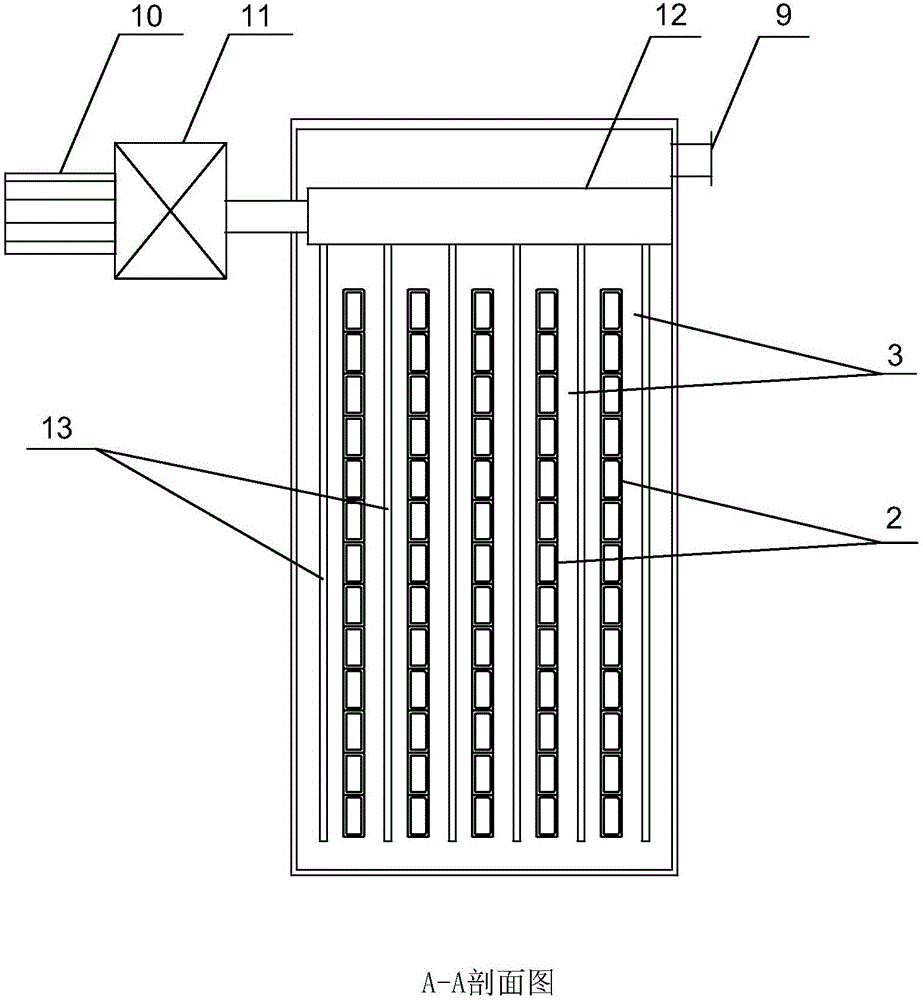

[0033] Specific implementation mode one, such as Figure 1~2As shown, this embodiment consists of the following steps: (1) A plurality of heat exchange tubes 1 form a heat exchange tube row 2 in the vertical direction, and a plurality of heat exchange tube rows 2 are arranged in parallel in the horizontal direction, and the plurality of heat exchange tubes 1 The two ends are respectively connected with the left header 4 and the right header 5, and there is a distance of 10-80 mm between each two heat exchange tube rows 2, and the cold water flows within this distance, which is called the cold water wide flow channel 3. The antifreeze aqueous solution with a temperature between 0°C and -6°C flows in each heat exchange tube, and flows back and forth between the left header 4 and the right header 5 to form a multi-tube flow. The antifreeze aqueous solution is in the During the flow process, heat is exchanged with the cold water through the heat exchange tube wall. After the cold ...

specific Embodiment approach 2

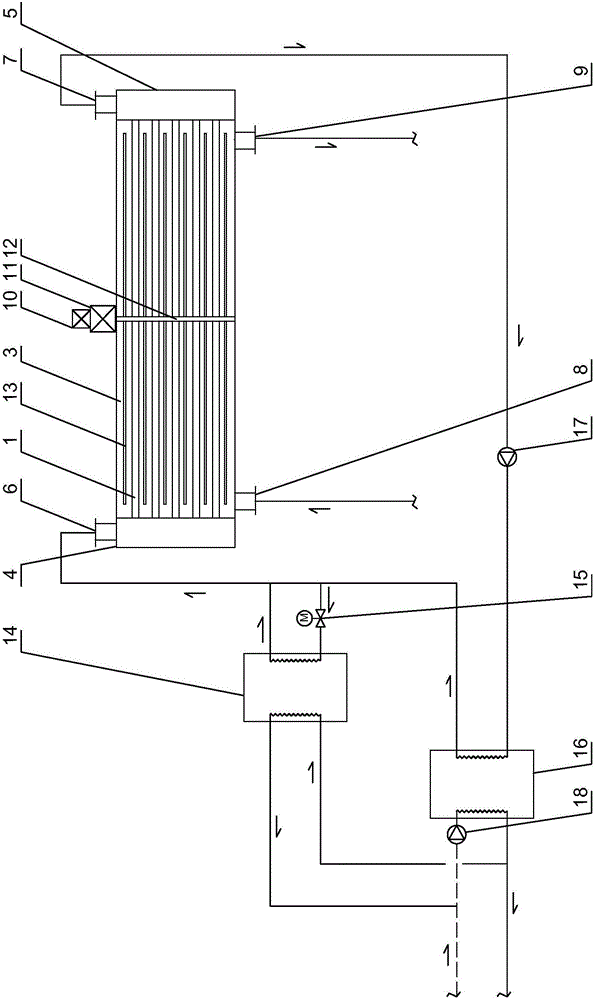

[0034] Specific implementation mode two, such as image 3 As shown, a method for collecting latent heat of cold water solidification in this embodiment is to set an antifreeze aqueous solution circulation pump 17 and a heat pump unit 16 on the basis of the specific embodiment one, and the antifreeze aqueous solution circulates repeatedly between the heat exchange tube 1 and the heat pump unit 16 .

specific Embodiment approach 3

[0035] Embodiment 3. In this embodiment, the distance between two heat exchange tube rows 2 is 20-60 mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap