Method for predicting instantaneous cutting force of milling based on maximum cutting force

A technology of instantaneous cutting force and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficulty in accurately predicting the instantaneous cutting force and instantaneous maximum cutting force of milling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

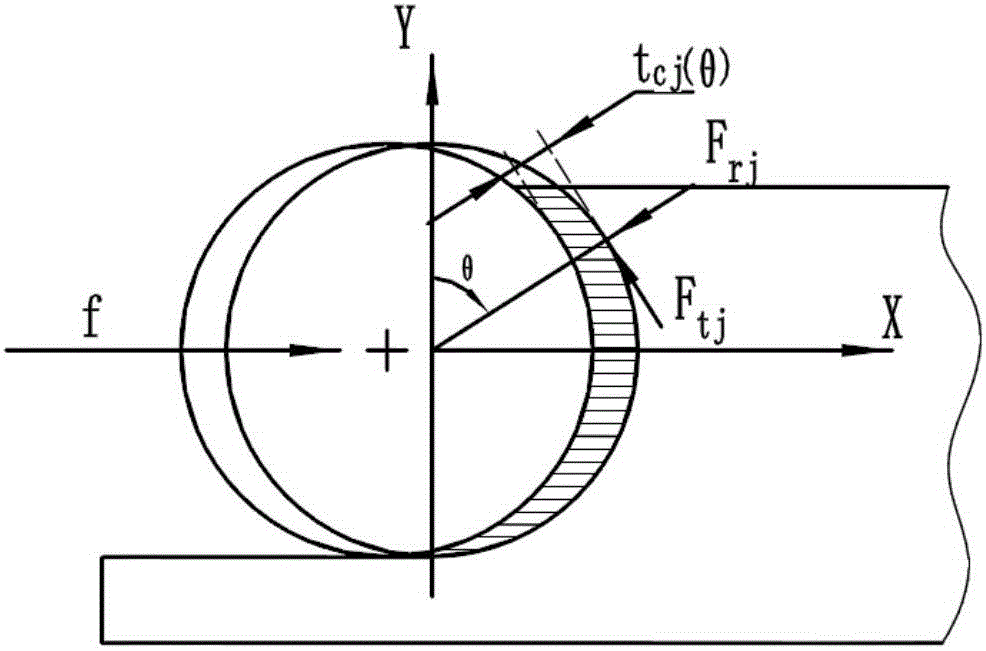

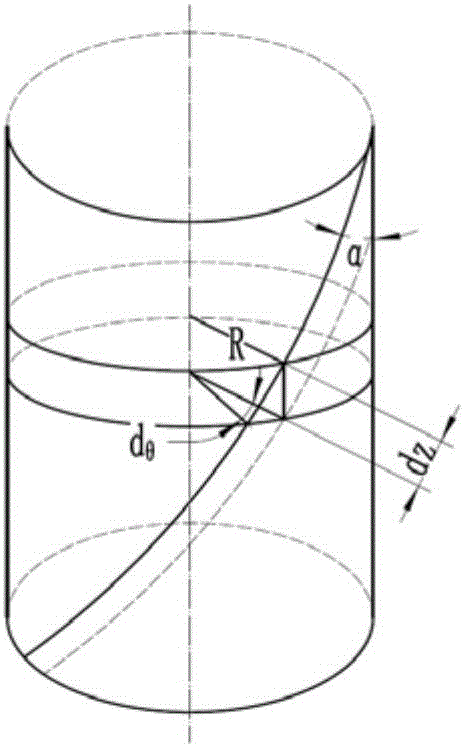

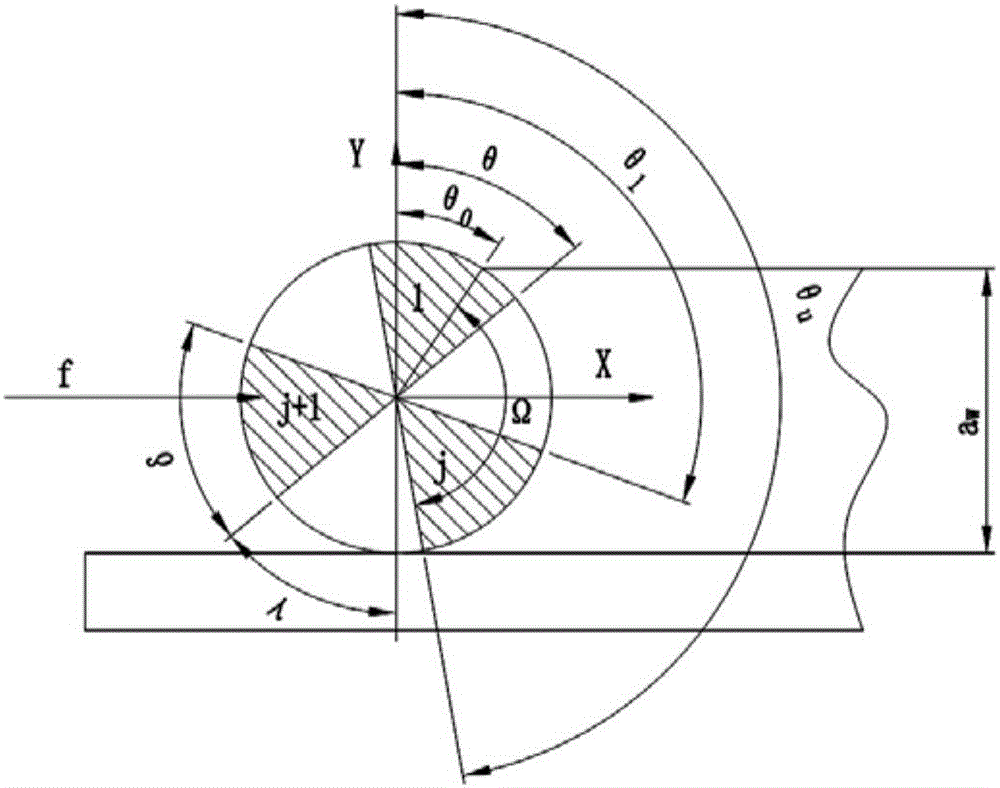

[0061] refer to Figure 1-9 . The specific steps of the milling instantaneous cutting force prediction method based on the maximum cutting force of the present invention are as follows:

[0062] Step 1: Establish the instantaneous cutting force prediction equation for milling aluminum alloy 7050-T7451.

[0063] 1. Decompose the area where the milling cutter participates in cutting along the z-axis into blades placed equivalent to the rake angle of the milling cutter, and act on the tangential microelement cutting force dF of the blade on the jth tooth tj (θ), radial micro-element cutting force dF rj (θ) and axial microelement cutting force dF aj (θ), the calculation formula of micro-element cutting force is as follows:

[0064]

[0065] In the formula, j=1, 2, 3, K t is the tangential cutting force coefficient, K r is the radial cutting force coefficient, K a is the axial cutting force coefficient, t cj (θ) is the radial instantaneous cutting layer thickness at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com