A 3D model-based multi-attribute decision-making quality detection method

A quality inspection method and multi-attribute decision-making technology, applied in design optimization/simulation, knowledge expression, special data processing application, etc. It has the effect of promoting the core manufacturing capacity, promoting the improvement of product quality and manufacturing efficiency, and reducing resource consumption and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

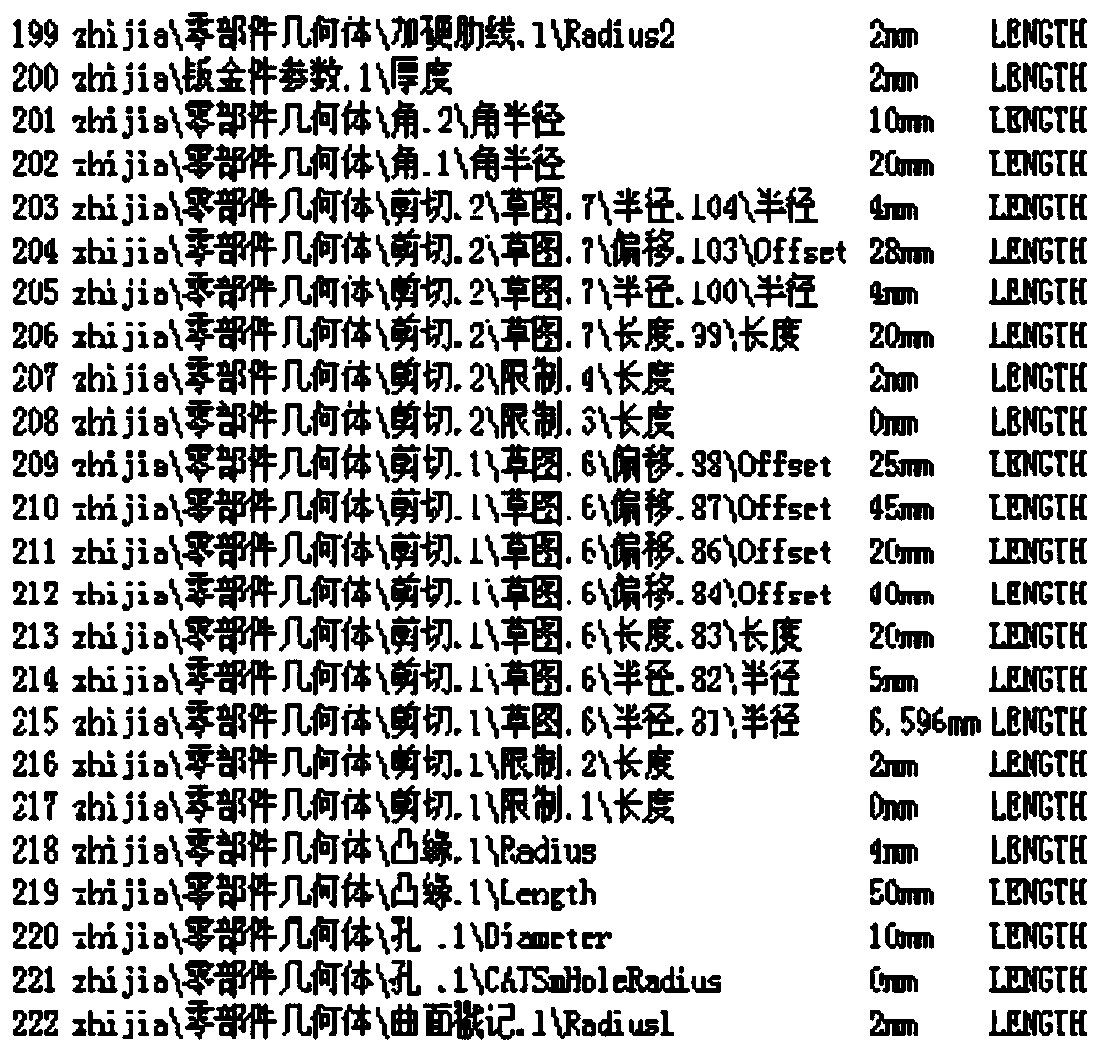

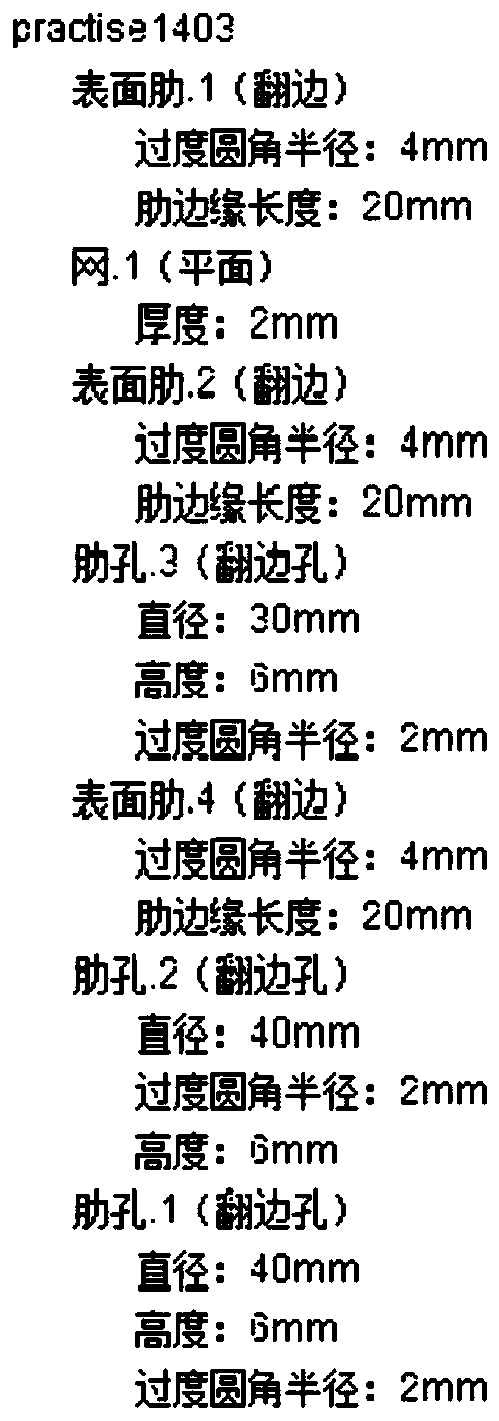

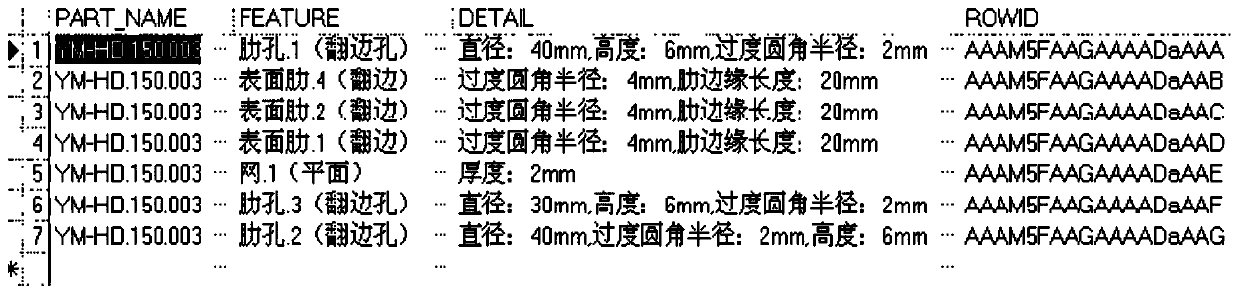

[0029] The purpose of the present invention is to provide an effective approach and method for the rationality, completeness, and quality stability of certain functions and performance levels of complex equipment quality testing in view of the characteristics of complex equipment such as multiple varieties, small batches, and high quality requirements. Aiming at the shortcomings of today's traditional quality inspection methods, this method adopts a method of quality inspection using multi-attribute decision-making means in a digital environment by combining with digital inspection methods. The integrated model of attribute decision-making quality inspection refers to the existing standards and specifications of complex equipment products to establish a quality inspection rule library for digital complex equipment parts, and uses inspection ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com