Experimental device of manual pressure source for testing multiple fluid pressure volume temperature relationship

A technology of experimental device and measuring device, applied in the direction of measuring device, teaching model, instrument, etc., can solve the problems of high labor cost, valve opening or closing, inability to carry out, etc., to achieve high experimental efficiency, reduced usage, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

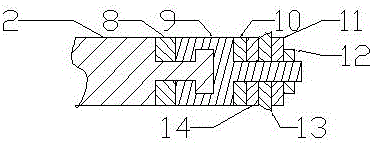

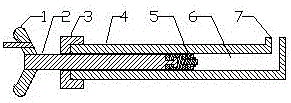

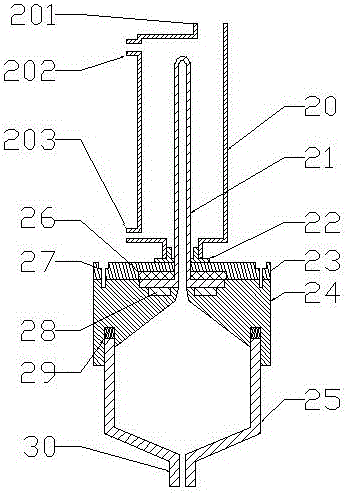

[0031] In order to further understand and illustrate the application of the invention, the relevant content in the manual pressure generator and the measuring device in the application of the invention will be further explained, and the implementation method of the invention will be described.

[0032]Because the bracket for fixing the manual pressure generator and the measuring device, the fixed structure of the manual pressure generator and the measuring device belong to the known, as the manual pressure generator and the measuring device use hexagonal steel to make, or use round steel bar or steel pipe to make the manual pressure generator The outside of the measuring device is processed into a hexagonal shape, or the surface of the manual pressure generator and the measuring device is welded for fixing and installing parts, so the structure and components of the fixing device are not shown in the figure.

[0033] Vacuum valve, inflation valve, pressure gauge and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com