Lithium ion battery anode pulp and preparation method thereof

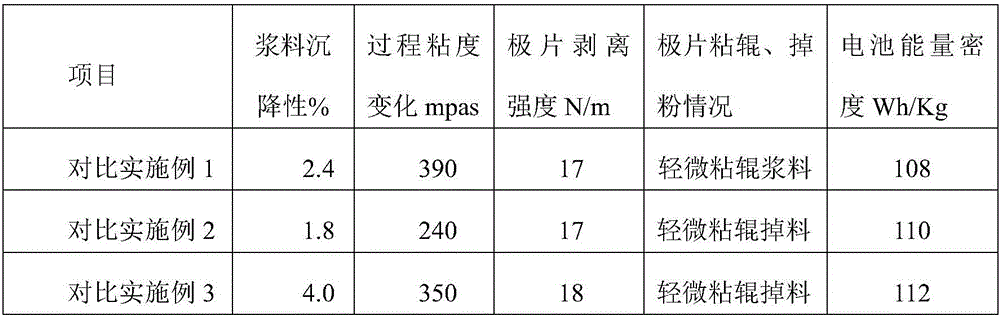

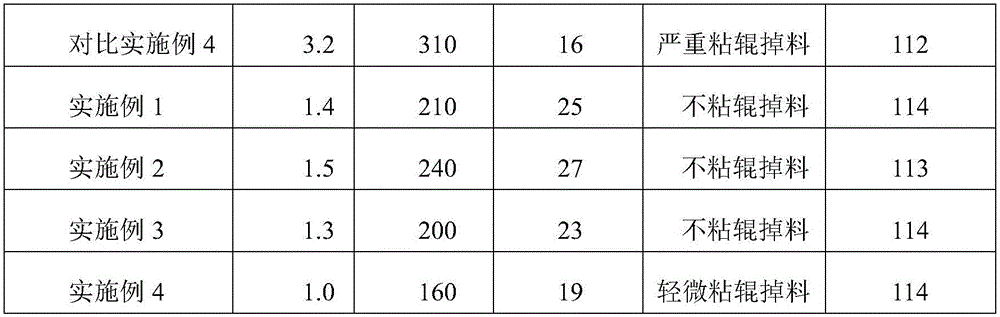

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of sticky roll dropping, low battery energy density, poor process yield, etc., so that it is not easy to drop powder, increase Energy density, the effect of increasing the ratio of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

[0033] (1) add the deionized water of the CMC of 0.5 weight part and 50 weight parts in agitator, stir 3h with the rotating speed of 800rpm, obtain CMC glue after stirring;

[0034] (2) Add 1 weight part of conductive carbon black to the CMC glue, and stir for 90min at a speed of 1500rpm;

[0035] (3) Add two equal parts of 96 parts by weight of artificial graphite into the agitator successively, and the stirring rate is 500rpm when mixing starts. ;

[0036] (4) Add 2.5 parts of LA133 into the stirrer and stir at 800rpm for 30min;

[0037] (5) add deionized water to adjust the viscosity to 1500mpas;

[0038] (6) After evacuating to -0.085MPa for defoaming, the slurry is obtained by filtering through a filter screen, and the viscosity of the slurry is 1250mpas.

Embodiment 2

[0040] This embodiment provides a preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

[0041] (1) add the CMC of 0.8 weight part and the deionized water of 50 weight parts in agitator, stir 3h with the rotating speed of 800rpm, obtain CMC glue after stirring;

[0042] (2) Add 1 weight part of conductive carbon black to the CMC glue, and stir for 90min at a speed of 1500rpm;

[0043] (3) Add two parts of 95.2 parts by weight of artificial graphite into the agitator in turn, and the stirring rate is 500rpm when mixing starts. ;

[0044] (4) Add 2.8 parts of LA133 into the stirrer, stir at 800rpm for 30min;

[0045] (5) add deionized water to adjust the viscosity to 1500mpas;

[0046] (6) After evacuating to -0.090MPa for defoaming, the slurry is obtained by filtering through a filter screen, and the viscosity of the slurry is 1250mpas.

Embodiment 3

[0048] This embodiment provides a preparation method of lithium ion battery negative electrode slurry, comprising the following steps:

[0049] (1) add the CMC of 0.7 weight part and the deionized water of 50 weight parts in agitator, stir 3h with the rotating speed of 800rpm, obtain CMC glue after stirring;

[0050] (2) Add 1 weight part of conductive carbon black to the CMC glue, and stir for 90min at a speed of 1500rpm;

[0051] (3) Add two equal parts of 96 parts by weight of artificial graphite into the agitator successively, and the stirring rate is 500rpm when mixing starts. ;

[0052] (4) Add 2.3 parts of LA133 into the stirrer, stir at 800rpm for 30min;

[0053] (5) add deionized water to adjust the viscosity to 1380mpas;

[0054] (6) After evacuating to -0.085MPa for defoaming, the slurry is obtained by filtering through a filter screen, and the viscosity of the slurry is 1180mpas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com