Pulse width adjustable laser

A technology of lasers and solid-state lasers, applied in the direction of lasers, laser components, phonon exciters, etc., to achieve the effect of controllable laser pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

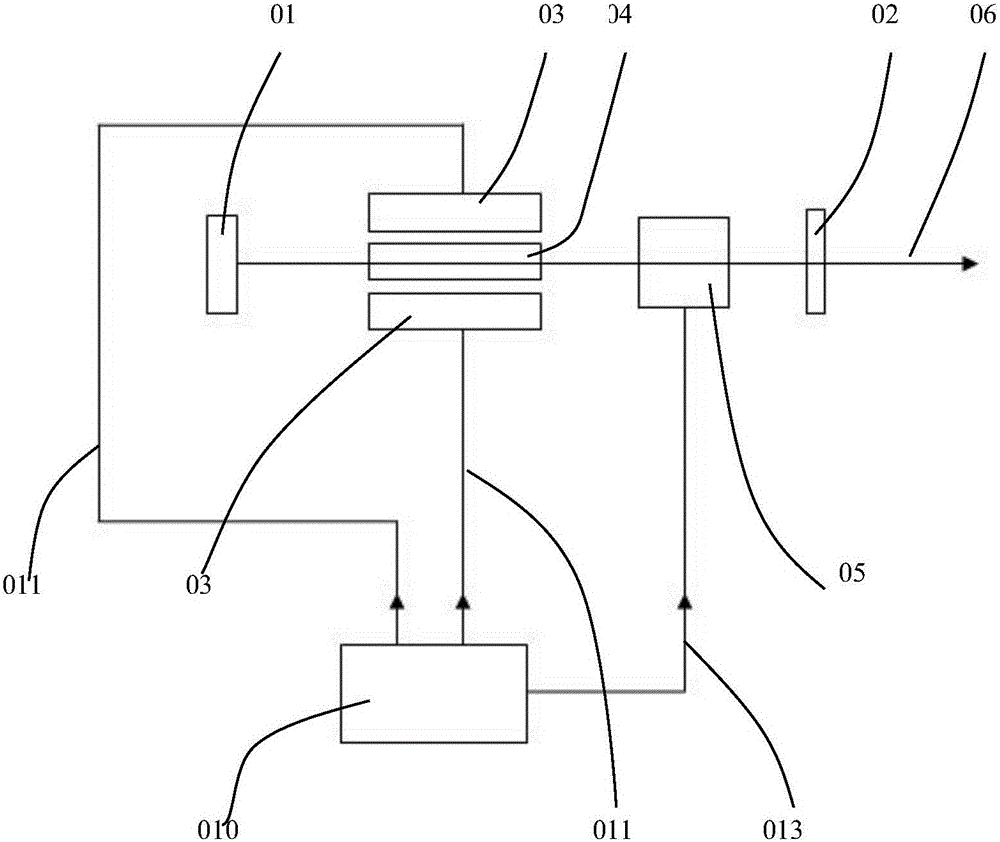

[0013] figure 1 A schematic diagram of a typical side-pumped solid-state laser is shown. Among them, 01 is a laser total reflection mirror, 02 is a laser output mirror, 04 is a solid-state laser working substance, 05 is an acousto-optic Q switch, and 06 is an output laser beam. 03 is a pump laser diode or a laser diode group, including possible optical beam shaping elements (not shown in the figure). The output pump beam (not shown in the figure) is coupled into the side of the laser working material. 010 is the power supply of the laser, its output 011 is used to drive the pumping diode 03, and the input 013 provides the driving electrical signal for the acousto-optic Q switch 05.

[0014] Since the pump light is coupled to the side of the laser working material directly or after being focused, the pump intensity in the pumped area is correspondingly low, which is different from that of laser TEM. 00 The area overlap of the working mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com