Self-driven switching type frictional nanometer generator and friction generating method

A nano-generator and triboelectric power generation technology, applied in the direction of triboelectric generators, etc., can solve the problems of inability to obtain high-frequency electrical output, small output current and output power, and inability to meet the needs of high-frequency power supply for electronic devices. The effect of output performance, increasing output current, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

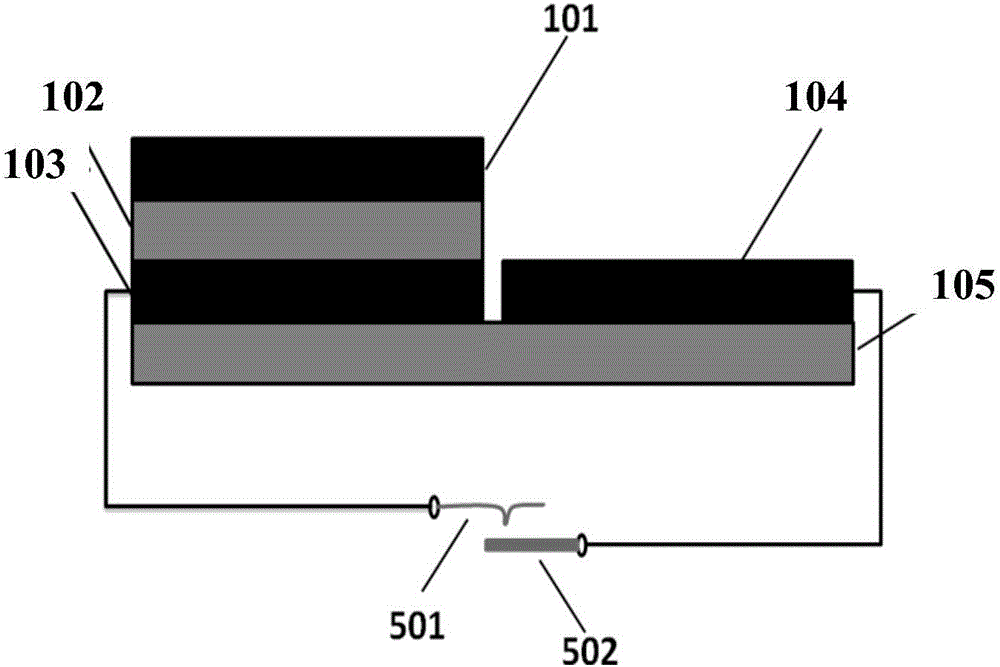

[0060] image 3 It is an embodiment of the triboelectric nanogenerator of the present invention, wherein the triboelectric generating unit adopts a sliding friction layer free-moving structure (SFT) friction generating unit, and the voltage-driven switch K adopts an electrostatic vibration switch, hereinafter referred to as a self-driven electrostatic vibration switch type Frictional nanogenerators. The specific structure is: the triboelectric generating unit includes: a first substrate 101; a friction layer 102; a first electrode layer 103, a second electrode layer 104; . The electrostatic vibration switch includes an elastic vibrator 501 and a contact end 502, wherein the elastic vibrator 501 is connected to the first electrode layer 103 through a wire, and the contact end 502 is connected to the second electrode layer 104 through a wire.

[0061] The length of the electrostatic vibrating switch should be appropriate. Generally speaking, the longer the vibrating switch is,...

Embodiment 2

[0078] In this embodiment, the voltage-driven switch adopts an air ionization switch, and the friction nanogenerator can be called a self-driven air ionization switch type friction nanogenerator. For the specific structure, see Figure 9 , is a typical structure of a self-driven air ionization switch type friction nanogenerator, including: a first substrate 101, a first friction layer 102 arranged on the lower surface of the first substrate 101; a first electrode is arranged on the upper surface of the second substrate 105 in contact layer 103 and the second electrode layer 104; wire 401, the first electrode layer 103 is connected to the discharge needle 201; wire 402, the second electrode layer 104 is connected to the collector plate 202; air ionization switch, including the discharge needle 201, There is an air gap between the collector plate 202 and the discharge needle 201 and the collector plate 202 . When air breakdown occurs between the discharge needle 201 and the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com