High-pressure annular electrode

A ring-shaped electrode and electrode technology, applied to electrical components, electric heating devices, heating by discharge, etc., can solve the problems of electrode ablation, bulging deformation, etc., and achieve the effect of improving pressure bearing strength, good cooling, and enhancing magnetic rotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The object of the present invention is to provide a high-voltage annular electrode, which is used to realize the long-term operation of the arc heater under the condition of high arc chamber pressure.

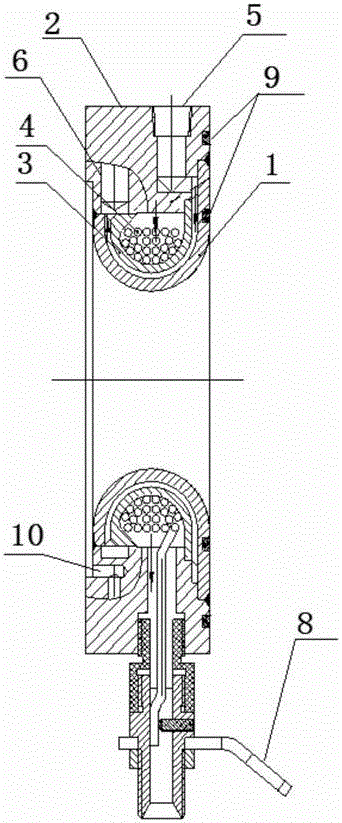

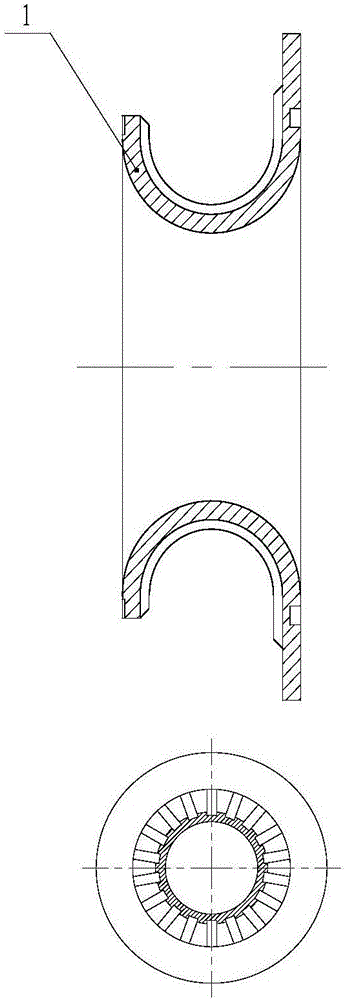

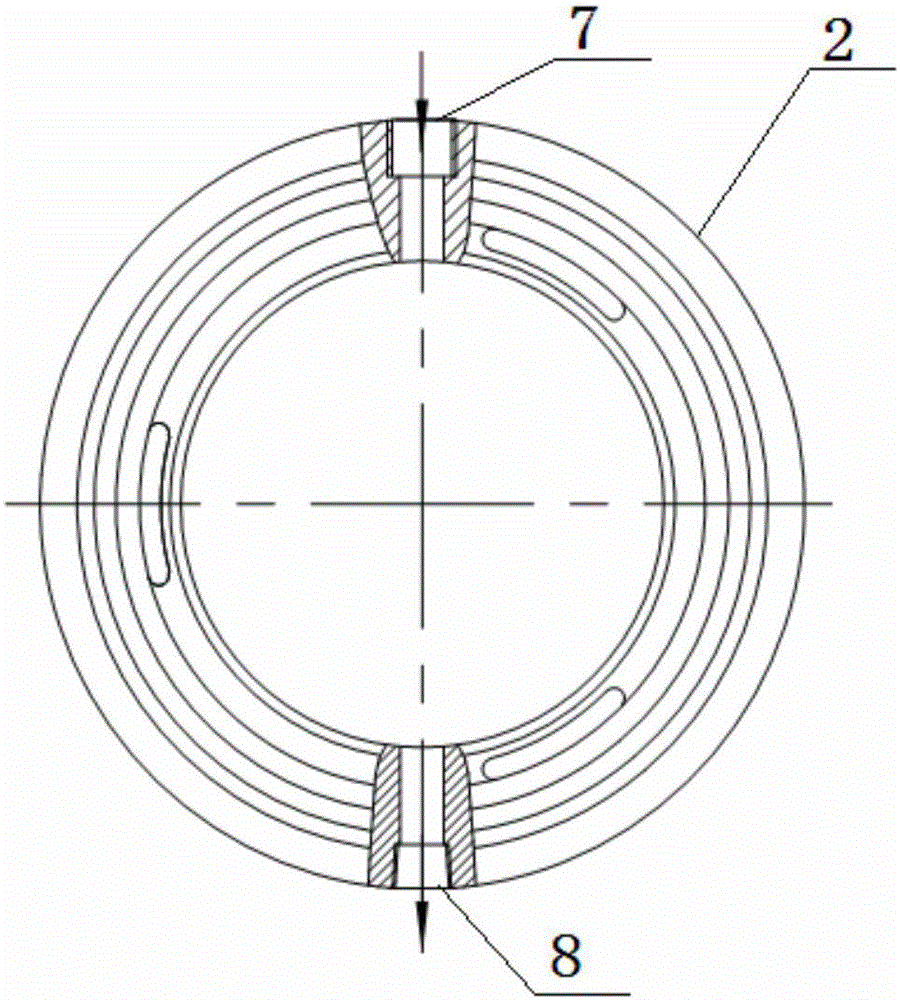

[0025] Such as figure 1 Shown is a schematic diagram of the structure of a high-voltage ring electrode. It can be seen from the figure that a high-voltage ring electrode includes an electrode inner sleeve 1, an electrode outer sleeve 2, a diversion block 3 and a magnetic field coil 4; the electrode outer sleeve 2 is a ring structure; the electrode inner sleeve 1 is fixedly installed on the inner wall of the electrode casing 2; the diversion block 3 is fixedly installed inside the electrode inner casing 1; and the magnetic field coil 4 is wound along the outer wall of the diversion block 3.

[0026] The electrode inner sleeve 1 is a ring s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com