Stable small-flow liquid evaporation system and evaporation technology thereof

A liquid evaporation, small flow technology, used in evaporation, evaporator accessories, evaporator adjustment/control, etc., can solve the problems of poor stability, required heat, easy heat loss, etc., to achieve the effect of stable gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

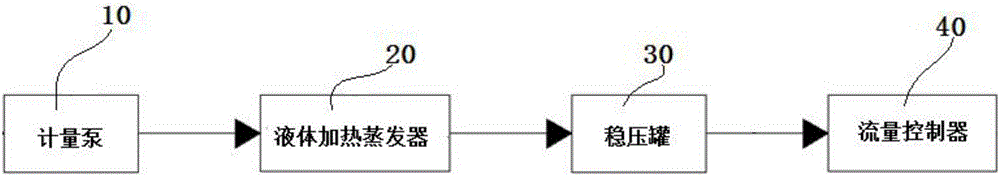

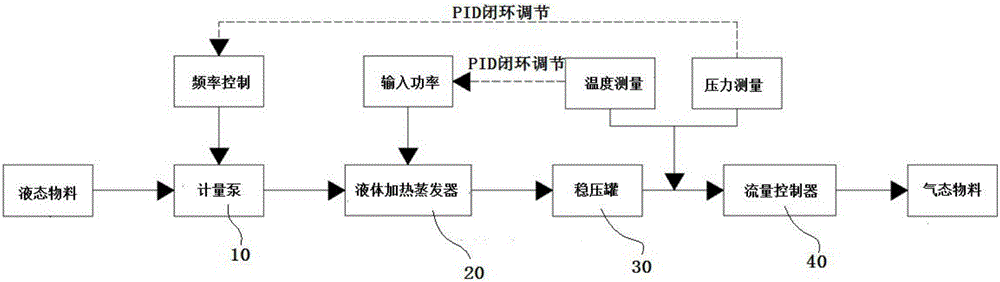

[0033] see figure 1 and figure 2 As shown, the present invention discloses a stable small-flow liquid evaporation system, which includes a metering pump 10 , a liquid heating evaporator 20 , a surge tank 30 and a flow controller 40 .

[0034] The metering pump 10 is used to transport liquid materials to the liquid heating evaporator 20. The metering pump 10 is equipped with a frequency converter. output of liquid materials.

[0035] The liquid heating evaporator 20 has the function of heating and evaporating the material from a liquid state into a gaseous state, and the liquid heating evaporator 20 is used for evaporating the liquid material delivered by the metering pump 10 into a gaseous material.

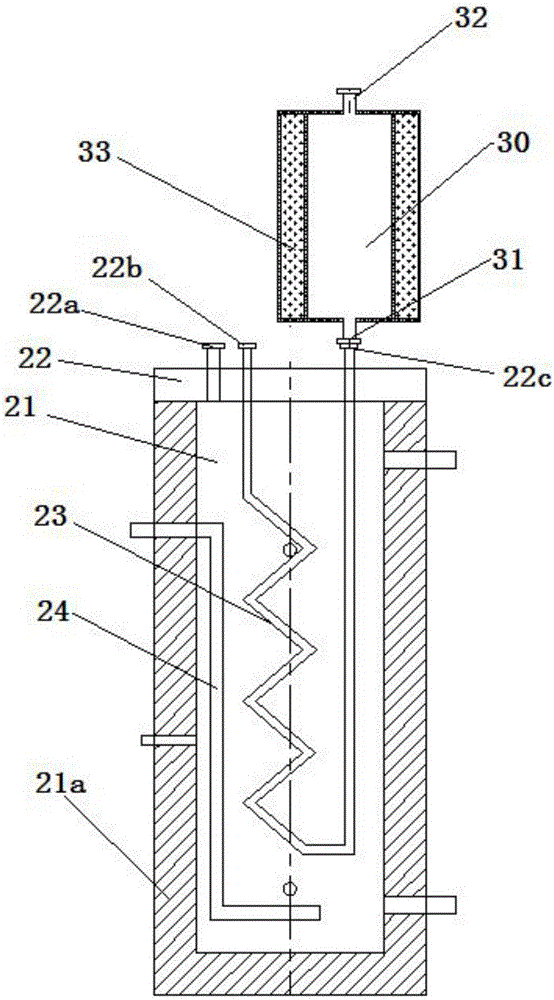

[0036] The liquid heating evaporator 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com