Air filter element cleaning device

A technology of air filter element and cleaning device, which is applied in gas treatment, smoke removal, transportation and packaging, etc., can solve the problems of complicated disassembly and assembly process of air filter element, affecting operation efficiency, increasing environmental protection pressure, etc., so as to improve the cleaning effect and improve the Cleaning efficiency, ensuring the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

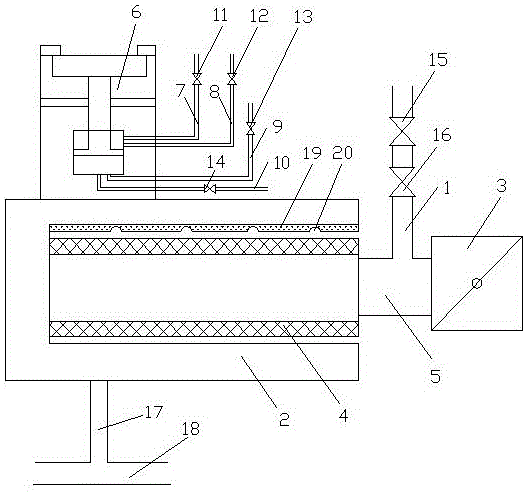

[0043] see figure 1 , an air filter element cleaning device, including a dust removal pipe 1, and also includes a drum cover 2, the dust removal pipe 1 is connected to the pipeline 5 between the intake butterfly valve 3 and the air filter element 4 of the main engine of the air compressor, The drum cover 2 is connected with a pneumatic control valve 6, and the pneumatic control valve 6 is connected with a first plunger inlet pipe 7, a first plunger exhaust pipe 8, a second plunger inlet pipe 9 and a second plunger inlet pipe. The plunger exhaust pipe 10, the first plunger intake pipe 7 is provided with a first intake switch valve 11, the first plunger exhaust pipe 8 is provided with a first exhaust switch valve 12, the second plunger intake pipe 9 is provided with a second intake switch valve 13, the second plunger exhaust pipe 10 is provided with a second exhaust switch valve 14, and the dust cleaning pipe 1 is provided with an intake valve 15 and a pressure reducing valve 16...

Embodiment 2

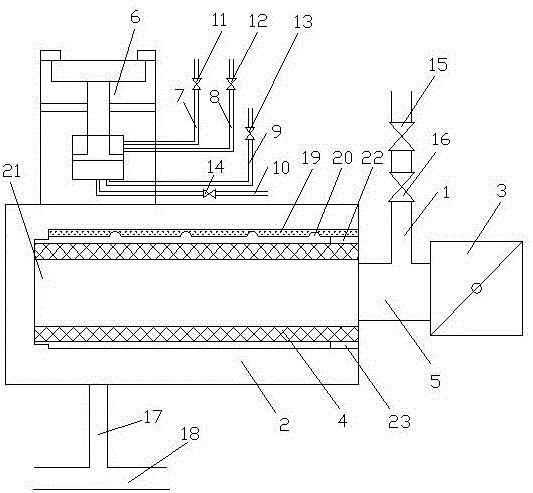

[0046] see figure 2 , an air filter element cleaning device, including a dust removal pipe 1, and also includes a drum cover 2, the dust removal pipe 1 is connected to the pipeline 5 between the intake butterfly valve 3 and the air filter element 4 of the main engine of the air compressor, The drum cover 2 is connected with a pneumatic control valve 6, and the pneumatic control valve 6 is connected with a first plunger inlet pipe 7, a first plunger exhaust pipe 8, a second plunger inlet pipe 9 and a second plunger inlet pipe. The plunger exhaust pipe 10, the first plunger intake pipe 7 is provided with a first intake switch valve 11, the first plunger exhaust pipe 8 is provided with a first exhaust switch valve 12, the second plunger intake pipe 9 is provided with a second intake switch valve 13, the second plunger exhaust pipe 10 is provided with a second exhaust switch valve 14, and the dust cleaning pipe 1 is provided with an intake valve 15 and a pressure reducing valve 1...

Embodiment 3

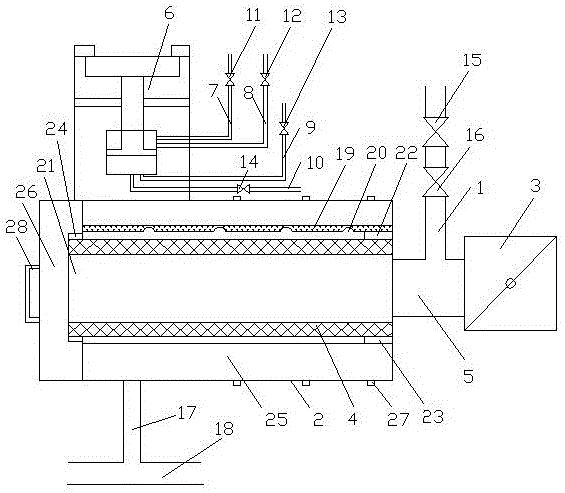

[0051] see image 3 , an air filter element cleaning device, including a dust removal pipe 1, and also includes a drum cover 2, the dust removal pipe 1 is connected to the pipeline 5 between the intake butterfly valve 3 and the air filter element 4 of the main engine of the air compressor, The drum cover 2 is connected with a pneumatic control valve 6, and the pneumatic control valve 6 is connected with a first plunger inlet pipe 7, a first plunger exhaust pipe 8, a second plunger inlet pipe 9 and a second plunger inlet pipe. The plunger exhaust pipe 10, the first plunger intake pipe 7 is provided with a first intake switch valve 11, the first plunger exhaust pipe 8 is provided with a first exhaust switch valve 12, the second plunger intake pipe 9 is provided with a second intake switch valve 13, the second plunger exhaust pipe 10 is provided with a second exhaust switch valve 14, and the dust cleaning pipe 1 is provided with an intake valve 15 and a pressure reducing valve 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com