Lithium battery material smashing and deironing device

A technology of lithium battery materials and crushing cylinders, which is applied in solid separation, chemical instruments and methods, grain processing, etc., can solve problems such as endangering health, wasting resources, and less raw materials, and achieves good working performance, simple design structure, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

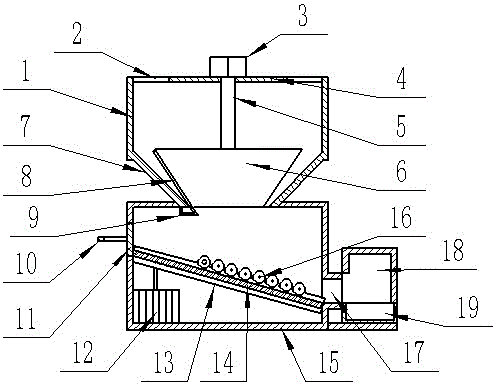

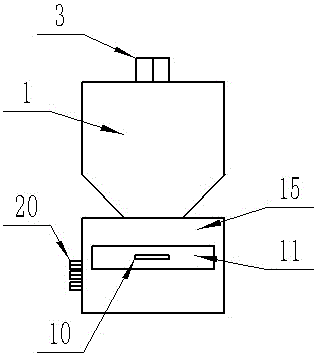

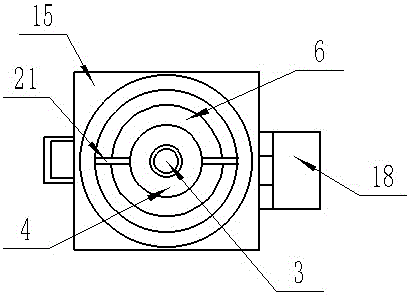

[0018] see Figure 1-4 , a device for crushing and removing iron from lithium battery materials, comprising a crushing cylinder 1 and an iron removal box 15; The first motor 3, the funnel barrel 7, the connecting rod 9 and the scraper 8; the feeding port 2 is arranged on the upper end surface of the crushing tube 1, and the feeding port 2 is convenient for workers to put lithium battery materials into the crushing tube 1; the described There are two support rods 21, which are respectively fixed horizontally in the middle of the front and rear edges of the feed port 2; the motor board 4 is horizontally fixed between the two support rods 21, and the motor board 4 is in the middle of the feed port 2 Position; the rotating shaft 5 is vertically arranged in the middle of the lower end surface of the motor plate 4; the middle position of the upper end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com