Improved tungsten-molybdenum flour milling machine

A grinding machine, tungsten and molybdenum technology, applied in the direction of grain processing, etc., can solve the problems of difficult reprocessing, brittle cracking of tungsten and molybdenum processed materials, and affect the life of tungsten and molybdenum, so as to save cleaning labor, speed up, and grind quickly and conveniently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

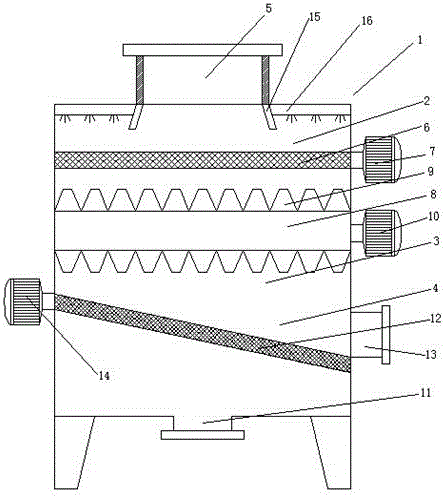

[0016] Such as figure 1 As shown, an improved tungsten-molybdenum mill of the present invention includes a casing 1, and the casing 1 includes a feed bin 2, a grinding bin 3, and a discharge bin 4 sequentially from top to bottom. Connected to the feed port 5, the feed bin 2 is provided with a vibrating screen 6, the side of the casing 1 is connected with a motor A7 that controls the vibrating screen 6, and the grinding bin 3 is provided with a main shaft 8 that runs through the casing 1, and the main shaft 8 Blades 9 are arranged on the top, and a motor B10 that drives the main shaft 8 to rotate is arranged outside the casing 1. The discharge bin 4 is connected to the discharge port 11, and the discharge bin 4 is provided with a discharge screen 12. The discharge screen 12 is connected to the The junction of the casing 1 is provided with a secondary discharge port 13, the discharge screen 12 is placed obliquely in the discharge bin 4, the secondary discharge port 13 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com