Automobile headlight lampshade bright surface machining method and cutting fluid for machining method

A processing method and bright surface technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of light spots, slow lighting speed, affecting product quality, etc., and achieve good cooling and cleaning effects, High hardness and smoothness, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

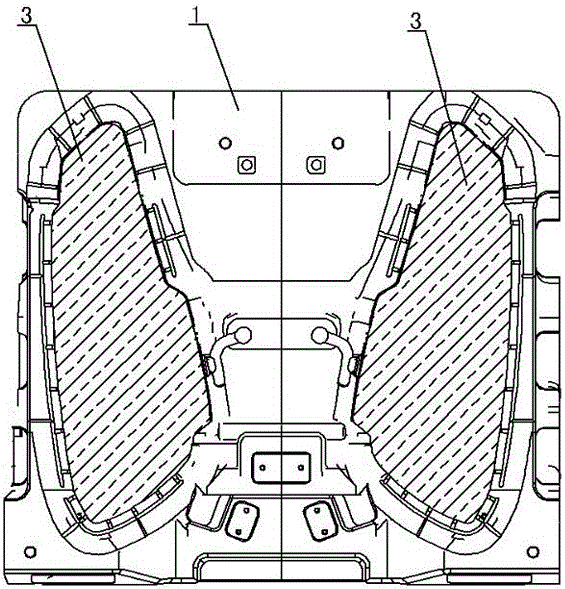

[0017] Example 1: Processing the bright surface of the cavity

[0018] 718 mold material is used, the tool is tungsten steel knife, the cutting amount is 0.2-0.4mm, the speed is 5000 rpm, the feed rate is 2500m / min, and the high temperature of 300-400 ℃ is generated during processing. At this time, spray atomized cutting The liquid will slowly lower the high temperature to 70-80°C. During the process of high temperature generation to lowering, it is equivalent to performing secondary heat treatment on the mold material, so that the hardness and brightness of the mold material are higher. And because the cavity surface is a groove-shaped insert, the atomized cutting fluid is used, and the cutting fluid is atomized during the machining process, and there is no liquid residue.

Embodiment 2

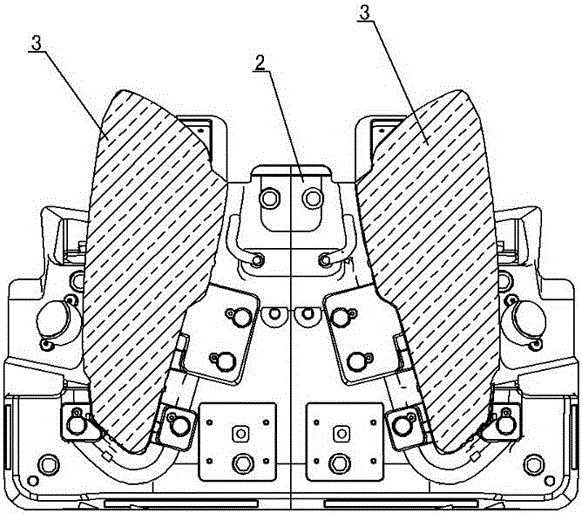

[0019] Embodiment 2: processing core bright surface

[0020] 718 mold material is used, the tool is tungsten steel knife, the cutting amount is 0.2-0.4mm, the speed is 5000 rpm, the feed rate is 2500m / min, and the high temperature of 300-400 ℃ is generated during processing. At this time, the cutting fluid is directly sprayed , because the core surface is a convex insert, the cutting fluid will flow away automatically after being sprayed, and can take away debris without cleaning the core. Its cooling effect is the same as that of the bright surface of the machining cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com