Z-direction enhancing method suitable for dry-state fiber preform

A preform and fiber technology, applied in the field of Z-direction reinforcement, can solve the problems of friction, which is difficult to eliminate the effect of cutting shear force, poor pin guiding effect, pin deflection, etc., to reduce the risk of instability and tilt, manufacturing Low cost, avoid tilting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

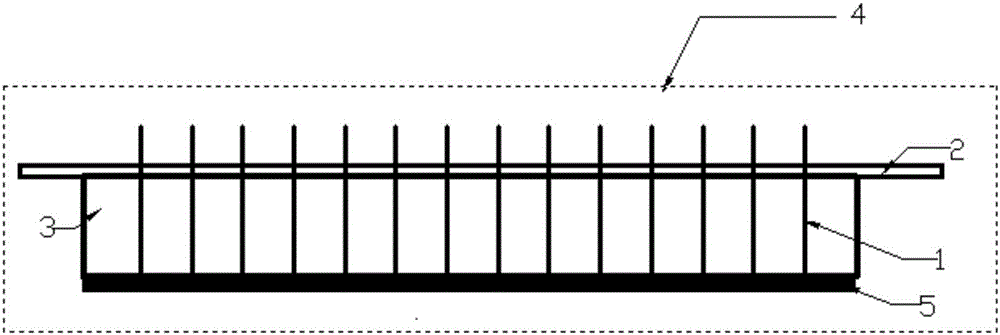

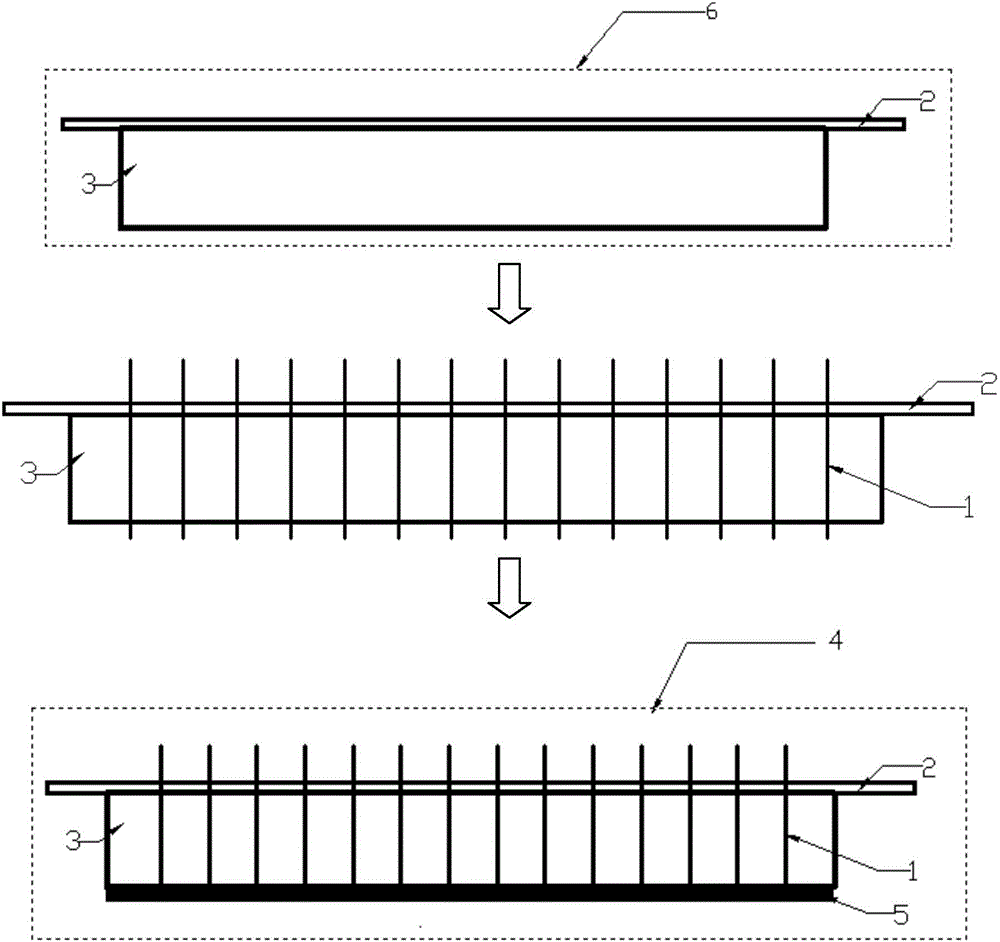

[0045] This embodiment relates to the preparation of Z-Pin implanted preforms.

[0046] 1) The perforated plate 2 is machined into shape by mechanical processing, the material of the perforated plate 2 is LY12CZ, the thickness after processing is 2mm, the hole diameter is 0.3mm, and the row spacing*column spacing of holes is 3mm*3mm;

[0047] 2) Place the foam layer 3 sequentially under the porous plate 2, the preferred material is low-density polystyrene foam to form the carrier layer 6;

[0048] 3) After impregnating QY8911 resin with 1K single-bundle T300 carbon fiber, it is prepared by pultrusion process Pin 1;

[0049]4) One end of the Pin needle 1 is implanted into the carrier layer 6 perpendicular to the surface of the porous plate 2 through the micropores of the porous plate 2, the Pin needle 1 penetrates the carrier layer 6, and the two ends of the Pin needle 1 protrude from the carrier layer 6 to form a pin containing pin. Needle carrier layer. Wherein, one end o...

Embodiment 2

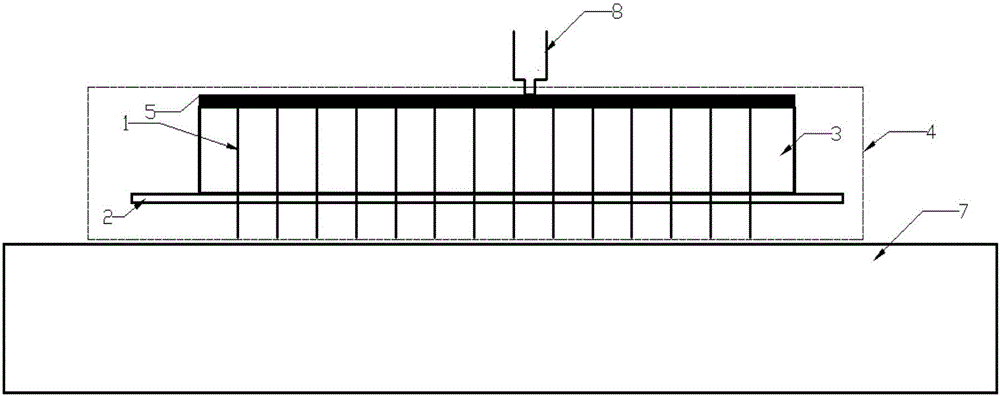

[0052] This embodiment relates to the use of the Z-Pin implanted preform of the present invention to reinforce a dry fiber preform.

[0053] The dry fiber preform to be reinforced is a flat plate structure, and the material is U7192 carbon fiber unidirectional woven fabric. The fabric is a T700 carbon fiber fabric from Daishan Feizhou New Material Co., Ltd. in Zhoushan City, Zhejiang Province. The external dimensions of the dry fiber preform are : 600mm×500mm×7mm (length×width×thickness), the layer is [45 / 0 / -45 / 90] 5s .

[0054] 1) Implant the Z-Pin into the preform 4 and make it according to the method described in Example 1;

[0055] 2) The Z-Pin is implanted into the Pin needle on one side of the porous plate 2 of the preform 4 and attached to the top of the dry fiber preform 7;

[0056] 3) Place the ultrasonic conversion device 8 above the adhesive coating 5 of the Z-Pin implant preform 4, and perform the implantation operation of the Pin needle 1 according to the instru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com