A flexible double-sided packaging substrate and its preparation method

A technology of encapsulating substrates and double sides, applied in chemical instruments and methods, lamination devices, instruments, etc., can solve problems such as stickiness and affecting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

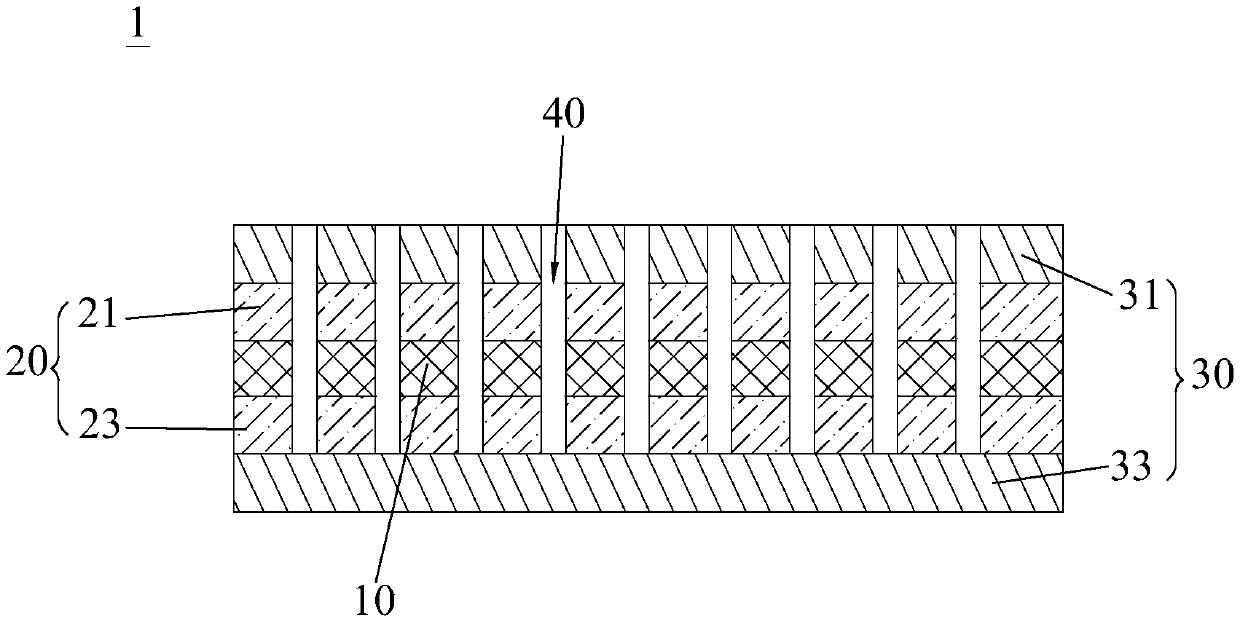

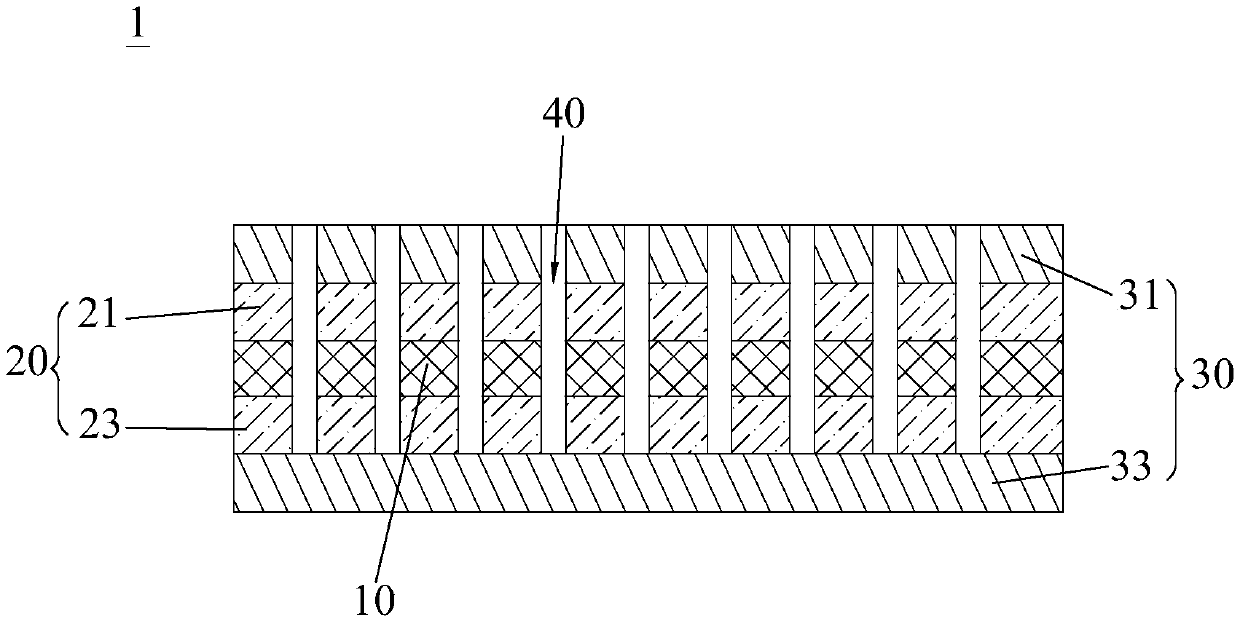

[0047] Production: first use epoxy resin composition, impregnate 1080 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain a prepreg adhesive sheet, and then bake the prepreg adhesive sheet at 190°C for 1.5 hours to obtain Completely cured cured sheet 10, then one side of the cured sheet 10 is first hot-pressed with an adhesive film 21 and then hot-pressed with a copper foil 31 and then cured, and then the other side of the cured sheet 10 is heated with another adhesive film 23 After pressing together, the whole material is punched, and finally the surface of the punched material's adhesive film 23 and another copper foil 33 are hot-pressed and then cured to make a double-interface application. The flexible double-sided packaging substrate 1.

Embodiment 2

[0049]Production: first use epoxy resin composition, impregnate 2116 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain a prepreg adhesive sheet, and then bake the prepreg adhesive sheet at 190°C for 1.5 hours to obtain Completely cured cured sheet 10, then heat press one side of the cured sheet 10 with an adhesive film 21 first, then hot press with copper foil 31 and then cure, and then hot press the other side of the cured sheet 10 with another adhesive film 23 After being combined together, the material is punched as a whole, and finally the surface of the glued film 23 of the punched material is combined with another copper foil 33 by hot pressing and post-cured to make a double-interface application. Flexible double-sided packaging substrate 1.

Embodiment 3

[0051] Production: first use epoxy resin composition, impregnate 3313 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain a prepreg adhesive sheet, and then bake the prepreg adhesive sheet at 190°C for 1.5 hours to obtain Completely cured cured sheet 10, then heat press one side of the cured sheet 10 with an adhesive film 21 first, then hot press with copper foil 31 and then cure, and then hot press the other side of the cured sheet 10 with another adhesive film 23 After being combined together, the material is punched as a whole, and finally the surface of the glued film 23 of the punched material is combined with another copper foil 33 by hot pressing and post-cured to make a double-interface application. Flexible double-sided packaging substrate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com