Automatic material selector based on rotating hooking manner

A technology of rotary hook and material selector, which is applied in packaging and other directions, can solve the time-consuming and labor-intensive problems of manual sorting of stainless steel welding pieces of window ears, and achieve the effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

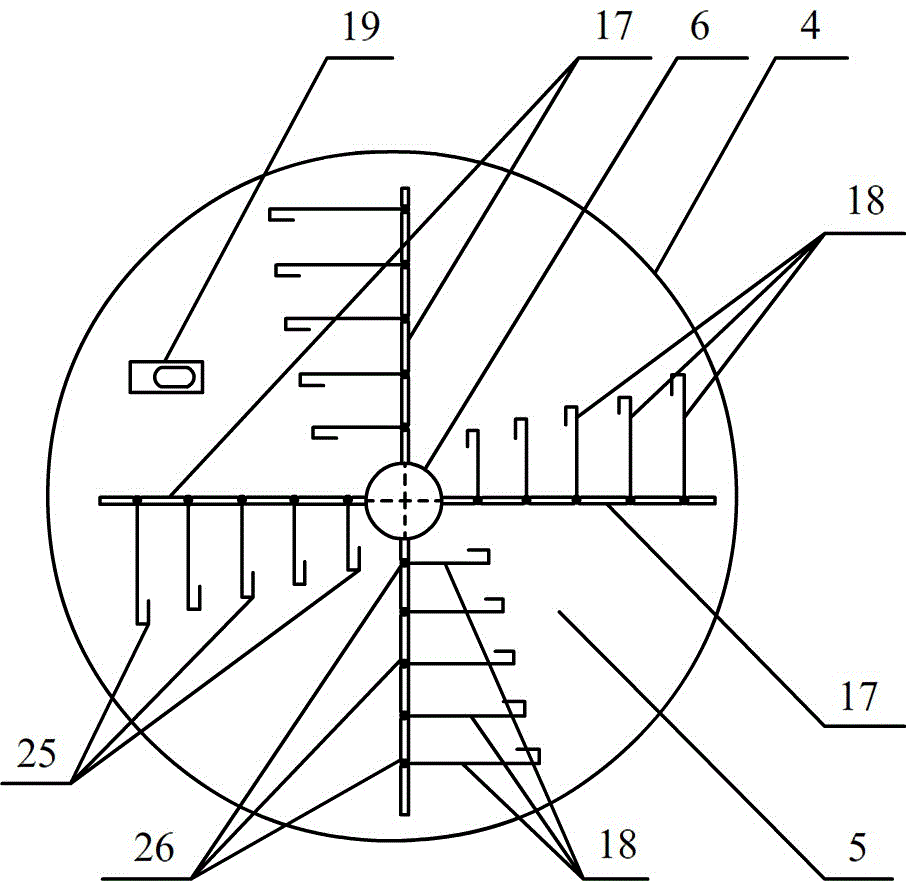

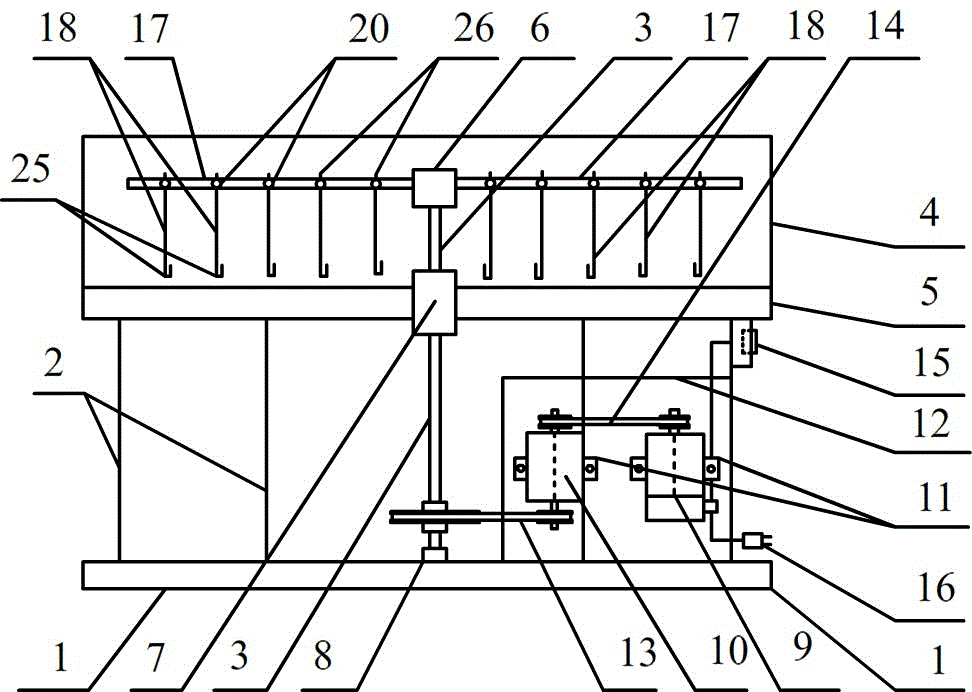

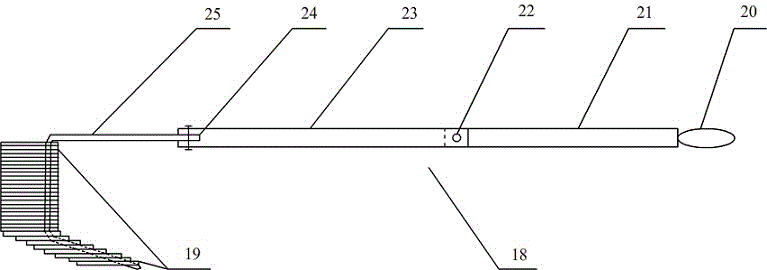

[0014] Example 1, such as figure 1 , figure 2 , image 3 As shown, an automatic material selector based on the rotary hooking method includes a base 1, a vertical support rod 2, a central rotating shaft 3, a material bucket 4, a bottom plate 5, a cross bar bracket 6, a bearing seat A7, and a bearing seat B8. Motor 9, gearbox 10, machine base with holes 11, vertical support plate 12, belt A13, belt B14, switch control box 15, power plug 16, horizontal hanging rod 17, material selection hook 18, window ear stainless steel welding piece 19. Hanging nails 26; the base 1 is a ring-shaped structure, and the bearing seat B8 is installed in the center of the ring, and the bearing seat B8 is fixedly connected with the surroundings of the ring through several horizontal spokes; the base 1 and several vertical spokes are supported by welding The rod 2 is fixedly connected, and the vertical support rod 2 is fixedly connected with the bottom plate 5 of the material bucket 4; a bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com