Anaerobic ammoxidation reaction device utilizing gas production for controlling water intake quantity

An anaerobic ammonium oxidation and reaction device technology, which is applied in the field of anaerobic ammonium oxidation reaction device, can solve the problems of high price, high operation cost, difficult maintenance, etc., and achieves the effect of reducing the time for restarting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

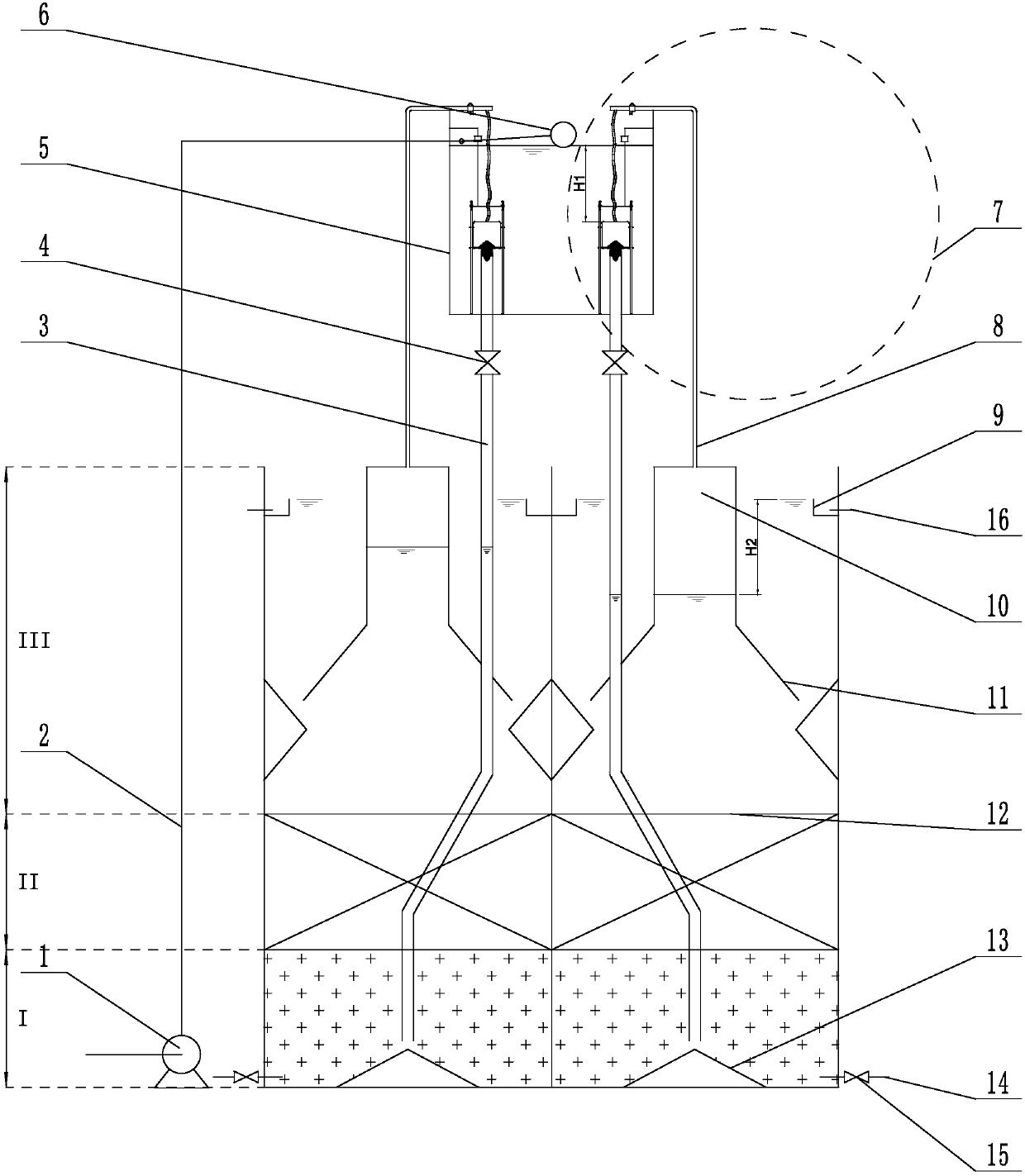

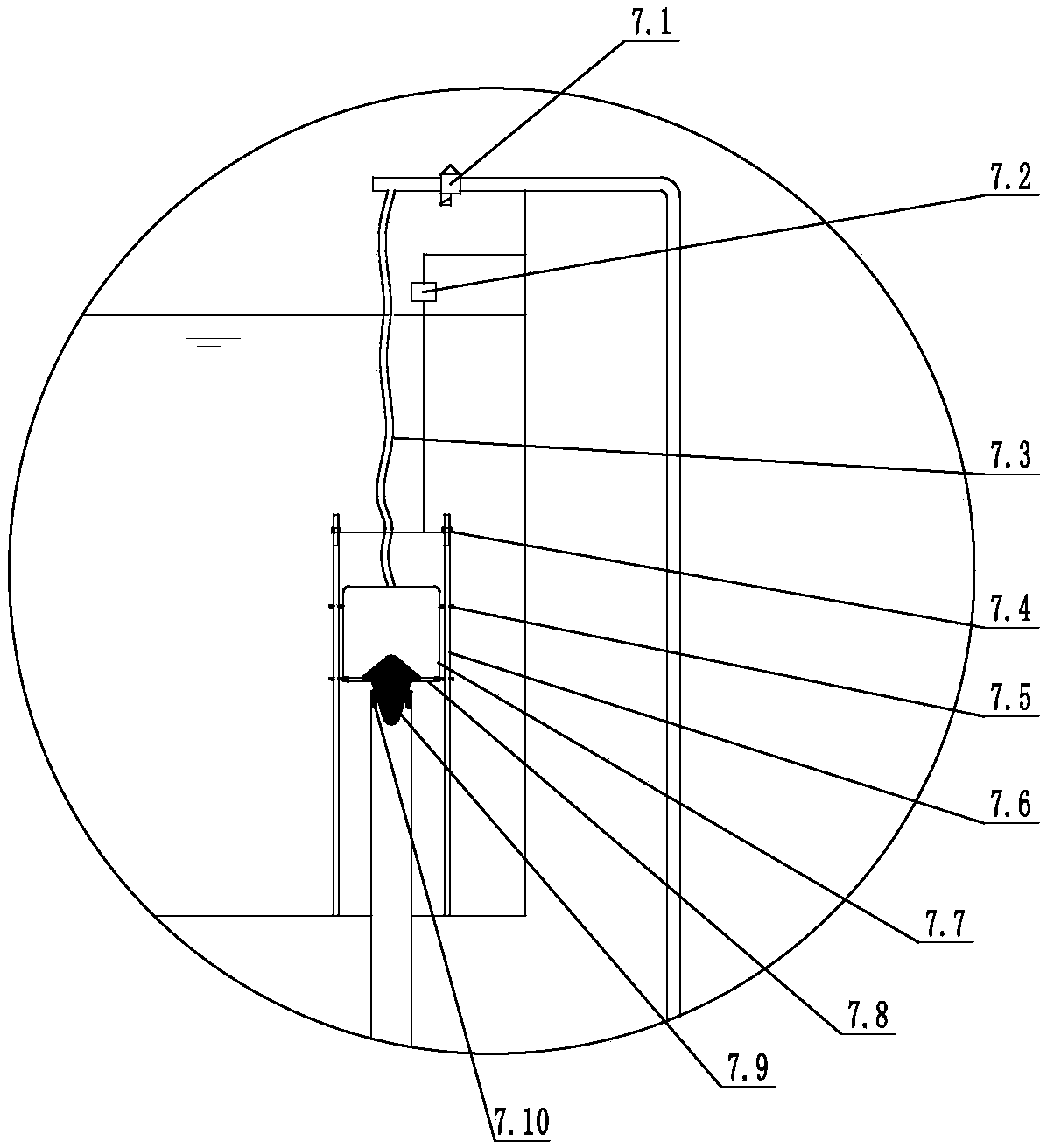

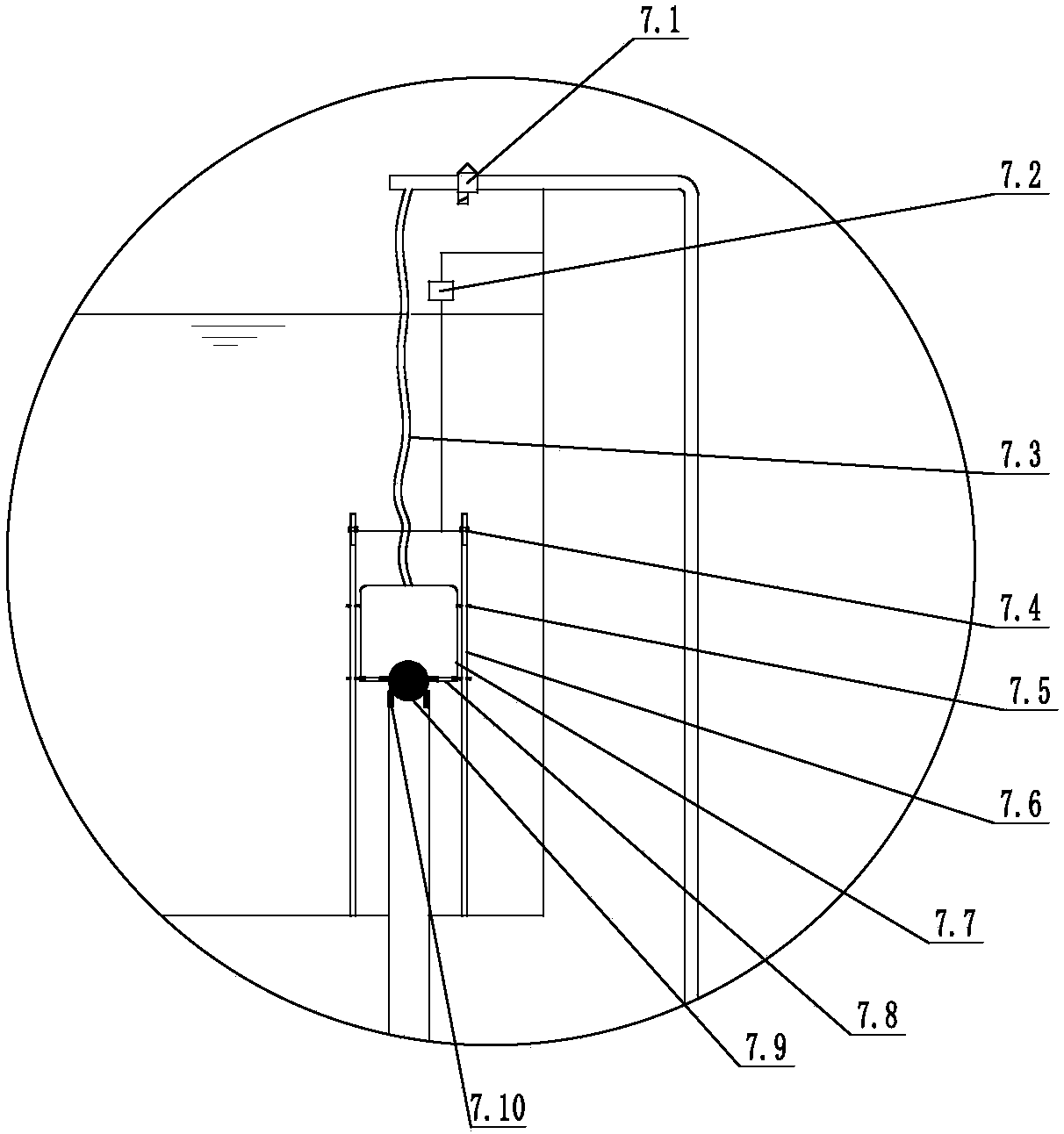

[0028] Such as figure 1 and 2 As shown, an anaerobic ammonium oxidation reaction device that uses gas production to control water intake includes two parallel UASB reaction devices, and a water inlet pump 1 is arranged next to the UASB reaction device; the UASB reaction device is set as a separation zone from top to bottom III. Packing area II and activated sludge area I. A three-phase separator 11 is provided in the separation area III, and an exhaust pipe 8 is provided on the air chamber 10 at the top of the three-phase separator 11; a packing layer 12 is provided in the packing area II The center of the bottom of the activated sludge area I is provided with a water inlet distributor 13, and the water inlet distributor 13 is directly above the water inlet pipe 3, and the water inlet pipe 3 is provided with a flow control valve 4 for controlling the flow of water, and the bottom of the activated sludge area I A mud discharge pipe 14 is provided on the side wall, and a mud di...

Embodiment 2

[0030] Such as figure 1 and 2 As shown, an anaerobic ammonium oxidation reaction device that uses gas production to control water intake includes two parallel UASB reaction devices, and a water inlet pump 1 is arranged next to the UASB reaction device; the UASB reaction device is set as a separation zone from top to bottom III. Packing area II and activated sludge area I. A three-phase separator 11 is provided in the separation area III, and an exhaust pipe 8 is provided on the air chamber 10 at the top of the three-phase separator 11; a packing layer 12 is provided in the packing area II The center of the bottom of the activated sludge area I is provided with a water inlet distributor 13, and the water inlet distributor 13 is directly above the water inlet pipe 3, and the water inlet pipe 3 is provided with a flow control valve 4 for controlling the flow of water, and the bottom of the activated sludge area I A mud discharge pipe 14 is provided on the side wall, and a mud di...

Embodiment 3

[0034] Such as figure 1 and 2 As shown, an anaerobic ammonium oxidation reaction device that uses gas production to control water intake includes two parallel UASB reaction devices, and a water inlet pump 1 is arranged next to the UASB reaction device; the UASB reaction device is set as a separation zone from top to bottom III. Packing area II and activated sludge area I. A three-phase separator 11 is provided in the separation area III, and an exhaust pipe 8 is provided on the air chamber 10 at the top of the three-phase separator 11; a packing layer 12 is provided in the packing area II The center of the bottom of the activated sludge area I is provided with a water inlet distributor 13, and the water inlet distributor 13 is directly above the water inlet pipe 3, and the water inlet pipe 3 is provided with a flow control valve 4 for controlling the flow of water, and the bottom of the activated sludge area I A mud discharge pipe 14 is provided on the side wall, and a mud di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com