Continuous preparation device and process of water-collecting net surface with bionic spider silk structure

A preparation device and spider silk technology, which is applied in the field of chemical bionics, can solve the problems of low production efficiency of water-collecting fibers, destruction of bionic water-collecting fibers, and low efficiency of water-collecting technology, so as to facilitate fault maintenance, increase the probability of collision, and reduce waste liquid Recycling efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

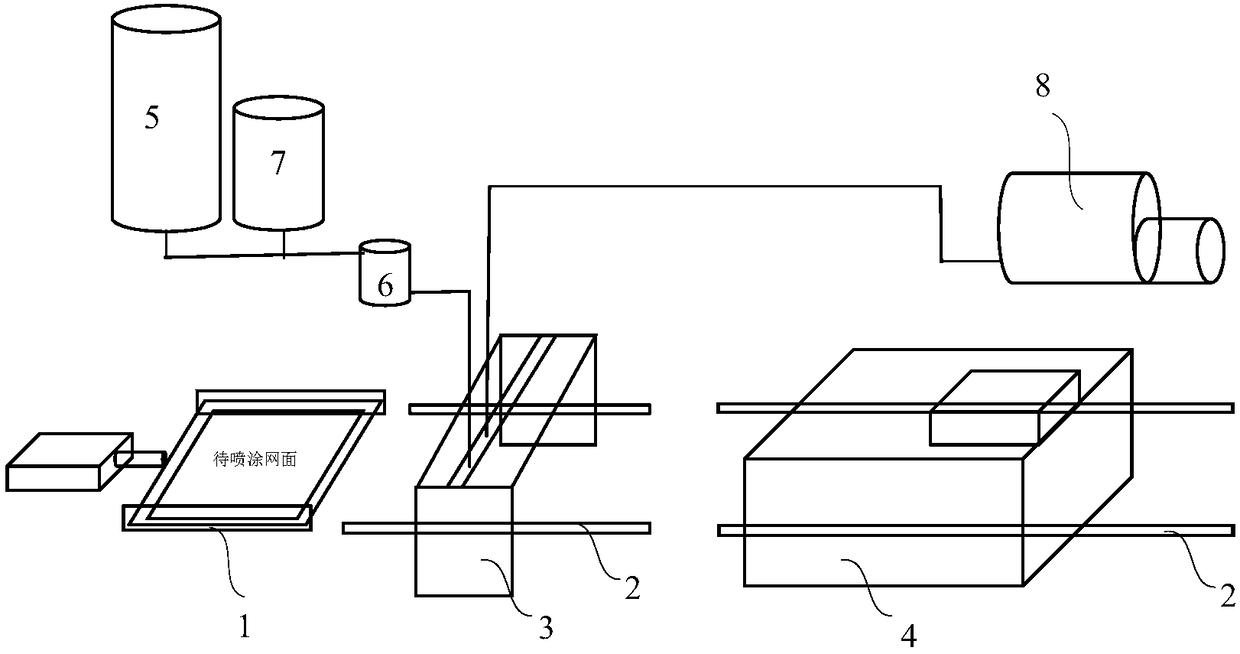

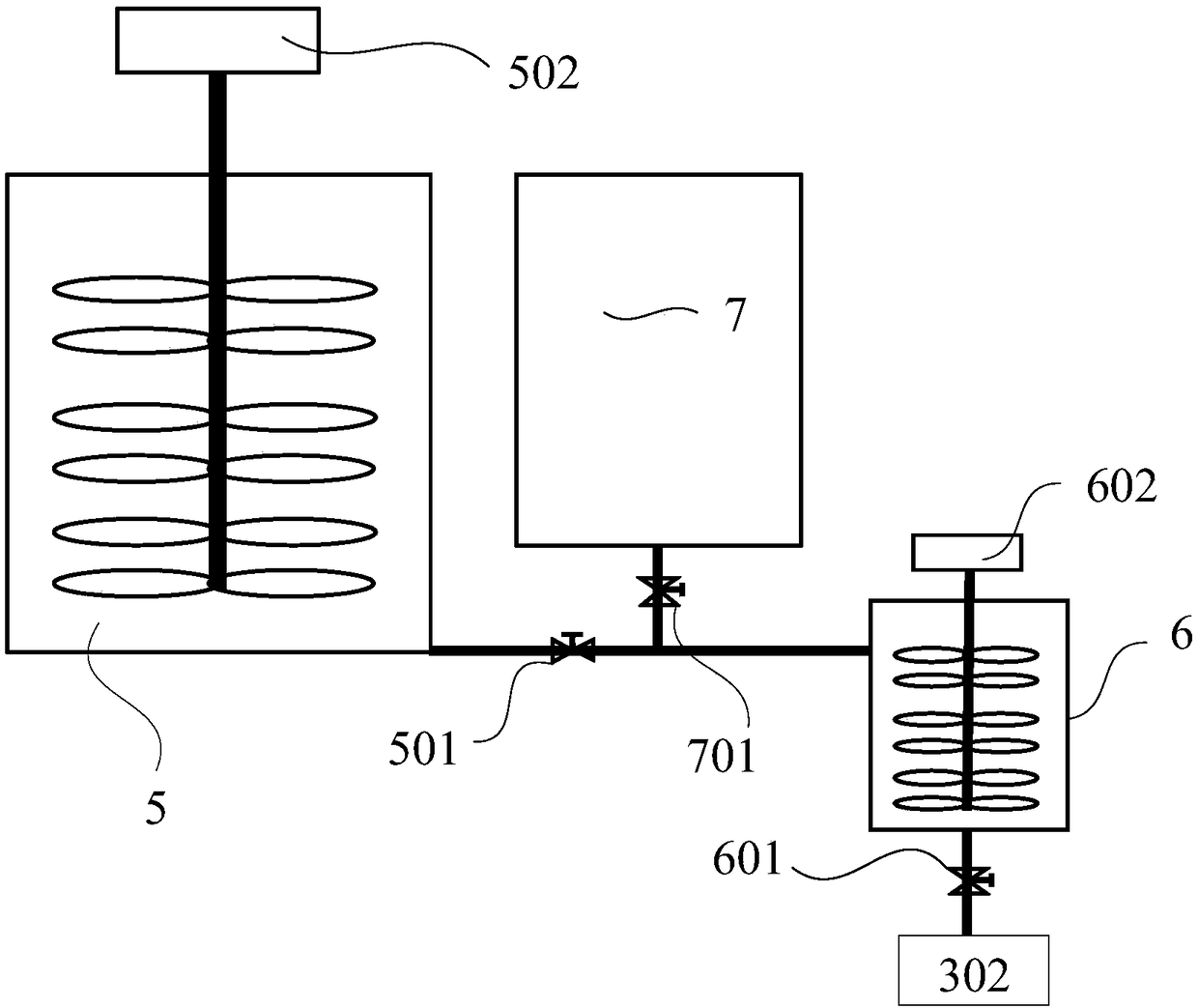

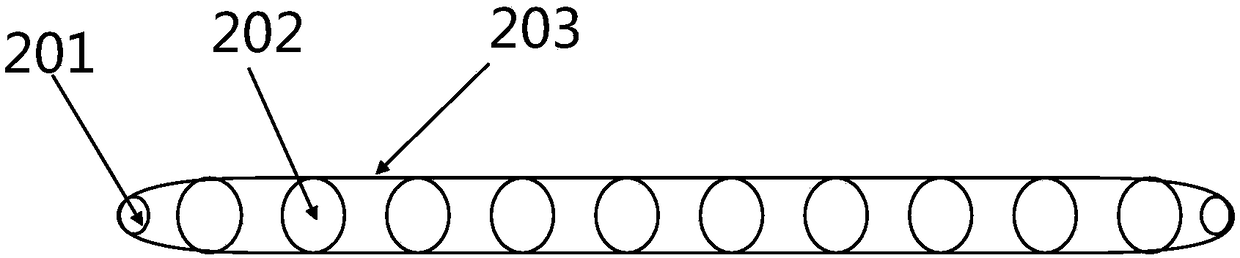

[0038] The present invention firstly provides a continuous preparation device for a water-collecting net surface with a bionic spider silk structure, such as figure 1 As shown, the shown device includes: push-in positioning table 1, transport guide rail 2, high-pressure spraying room 3, drying room 4, primary raw material tank 5, secondary raw material tank 6, cleaning stock solution tank 7 and air compression pump 8 . The push-in positioning table 1 is located on the transport guide rail 2, and the push-in positioning table 1 is fixed to the mesh surface to be sprayed. In the continuous preparation process, the push-in positioning table 1 carries the mesh surface to be sprayed. , along the transport guide rail 2, passing through the high-pressure spraying chamber 3 and the drying chamber 4 in sequence, realizing the continuous preparation of the water-collecting mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com